Injection molding part classification method and system based on image processing

A classification method and image processing technology, applied in the field of image processing, can solve problems such as insufficient filling, complex flow paths of injection molded parts, and many thin-walled areas, and achieve the effect of reducing the amount of calculation and efficient quality inspection of injection molded parts

Active Publication Date: 2022-05-06

江苏海辉塑胶制品有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The flow path of this kind of injection molded parts is complicated, there are many thin-walled areas, the thin ribs are widely distributed, and there are also many deep ribs, so it is easy to have insufficient filling

Existing technology detects insufficient filling of injection molded parts through template matching. On the one hand, template matching has a large amount of calculation. On the other hand, template matching cannot be effective when templates are missing. Difficult to segment out modules for template matching

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0054] This embodiment provides a system for classifying injection molded parts based on image processing, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the computer program is executed by the processor, an image-based classification system is implemented. Steps in the classification method for injection molded parts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

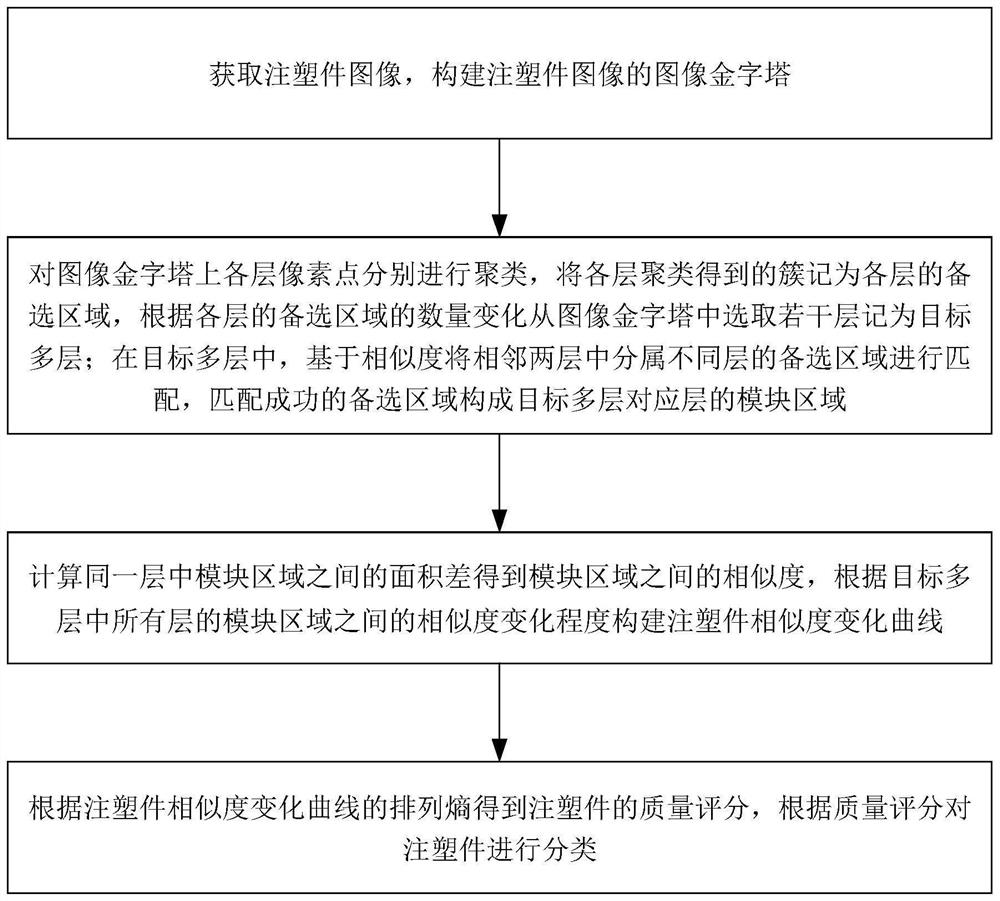

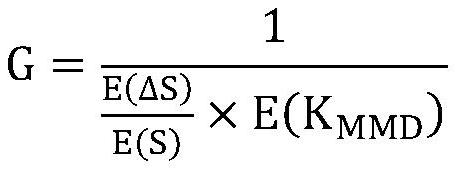

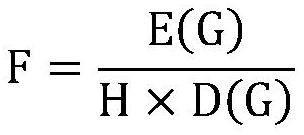

The invention relates to the field of image processing, in particular to an injection molding part classification method and system based on image processing, and the method comprises the steps: obtaining injection molding part images, and constructing an image pyramid of the injection molding part images; clustering pixel points of each layer on the image pyramid to obtain alternative areas of each layer, and selecting a plurality of layers from the image pyramid according to the number change of the alternative areas of each layer to be marked as target multiple layers; in the target multi-layer, obtaining a module area of a layer corresponding to the target multi-layer based on the similarity; the area difference between the module areas in the same layer is calculated to obtain the similarity between the module areas, and an injection molding part similarity change curve is constructed according to the similarity change degree between the module areas of all the layers in the target multiple layers; and obtaining quality scores of the injection molding parts according to the permutation entropy of the similarity change curve of the injection molding parts, and classifying the injection molding parts according to the quality scores. The calculation amount can be reduced, and the quality detection efficiency of the injection molded part is improved.

Description

technical field [0001] The invention relates to the field of image processing, in particular to a method and system for classifying injection molded parts based on image processing. Background technique [0002] Insufficient filling of injection molded parts means that when the molten plastic is injected, it does not completely fill a certain area in the mold cavity, that is, the product is not filled completely, and a part is missing, especially in thin-walled areas, thin ribs, deep ribs or The end region of the flow path. Especially in the production of small-scale and large-volume parts, there are multiple identical cavities on the same injection mold, and multiple parts connected by runners can be obtained in one injection molding, and one part is a module. The flow path of this kind of injection molded part is complicated, there are many thin-walled areas, the thin ribs are widely distributed, and there are also many deep ribs, so it is easy to have insufficient fillin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06T7/00G06T7/62G06K9/62G06V10/764

CPCG06T7/0004G06T7/62G06T2207/20016G06T2207/10004G06F18/23Y02P90/30

Inventor 张桂秋杨鸿登

Owner 江苏海辉塑胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com