Press-fitting wiring terminal equipment for connecting wire

A technology for connecting terminals and connecting wires, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of inability to straighten the connecting wires, unfavorable operation of pressing the terminals, and inability to regulate the specific position and angle of the terminals. Positioning accuracy and press-fitting efficiency, improving positioning accuracy and press-fitting effect, and improving the effect of press-fitting accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

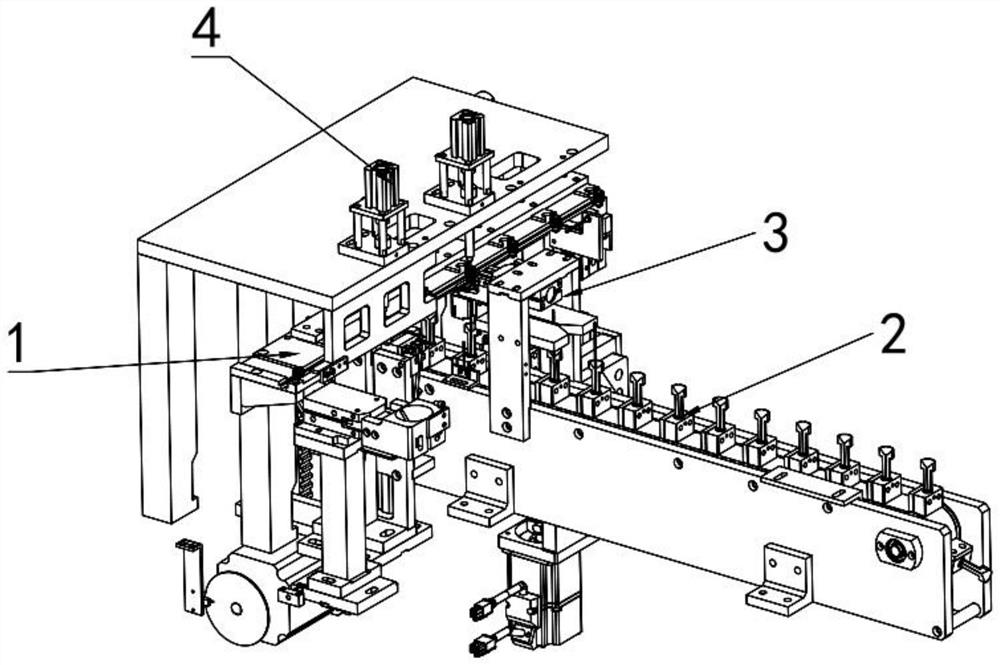

[0055] Example: see Figure 1 to Figure 3 , a press-fit terminal device for connecting wires provided in this embodiment, which includes:

[0056] The first feeding device 1 is used to transport the terminals along the first path;

[0057] a second feeding device 2 for feeding the connection line along the second path;

[0058] The crimping terminal station is formed by the intersection of the first feeding device 1 and the second feeding device 2;

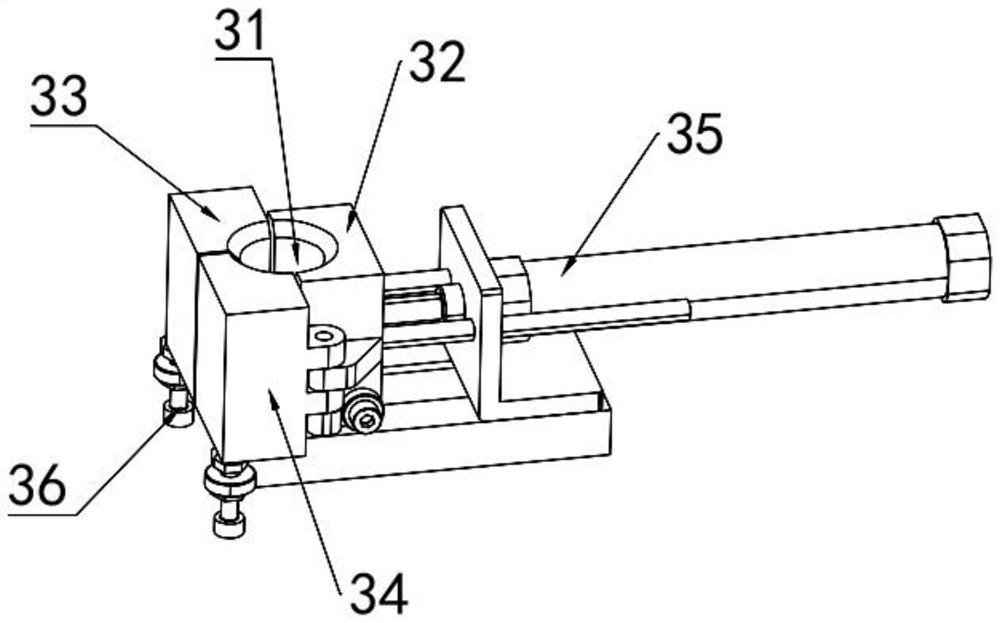

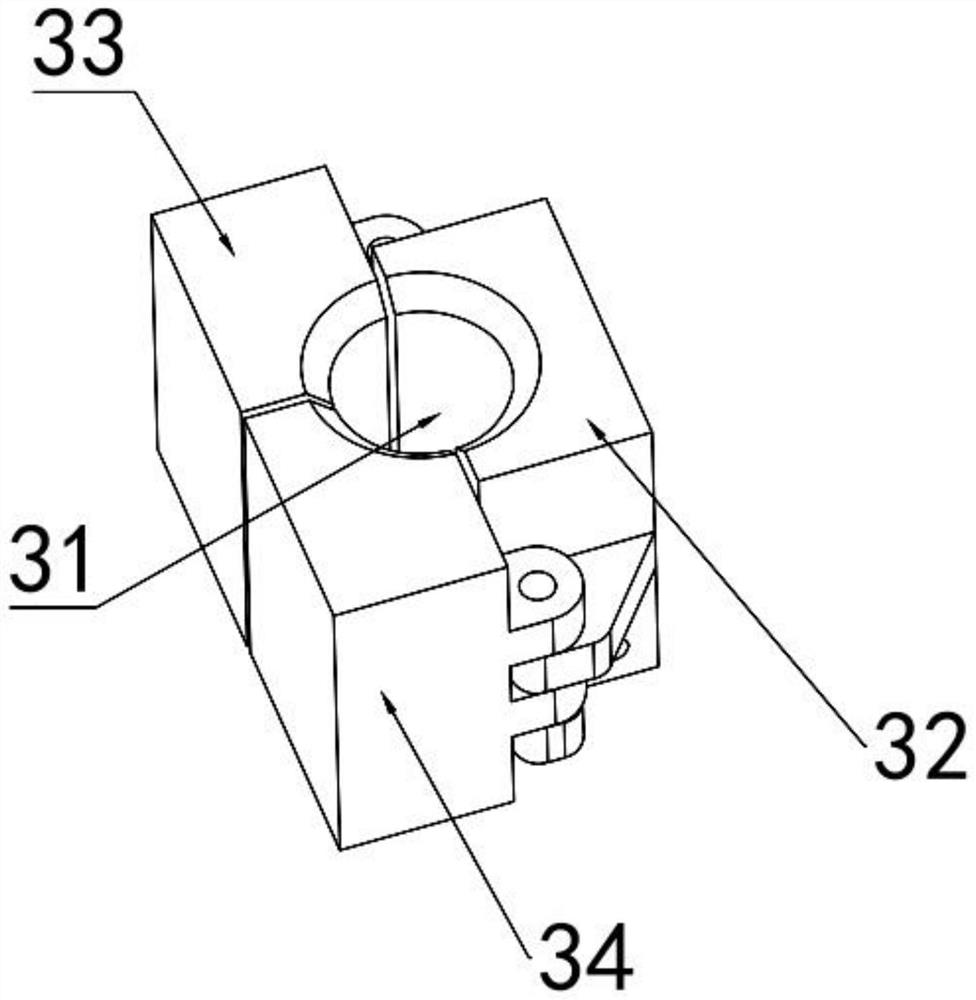

[0059] The positioning guide device 3 is arranged on the terminal crimping station, and is used to adjust the angle and position of the terminal to be crimped to accurately align the connecting wire to be crimped;

[0060] The crimping device 4 is arranged on the terminal crimping station corresponding to the positioning guide device 3, and is used for crimping the terminal on the connecting wire.

[0061] Specifically, by arranging the first feeding device 1 and the second feeding device 2, the terminals to be press-fitted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com