Oyster cleaning system

A cleaning system and technology for oysters, applied in slaughtering, bivalve processing, food science, etc., can solve the problems of inability to clean oysters, increase the cleaning workload, and unfavorable cleaning efficiency, so as to improve transportation stability and improve cleaning. , The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

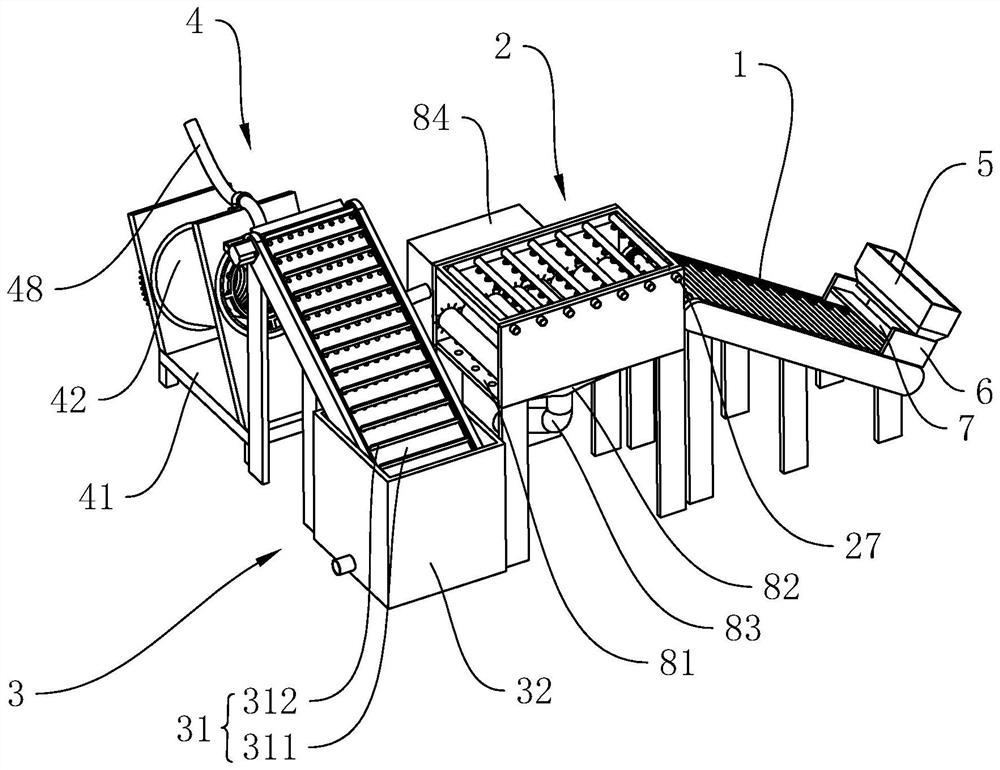

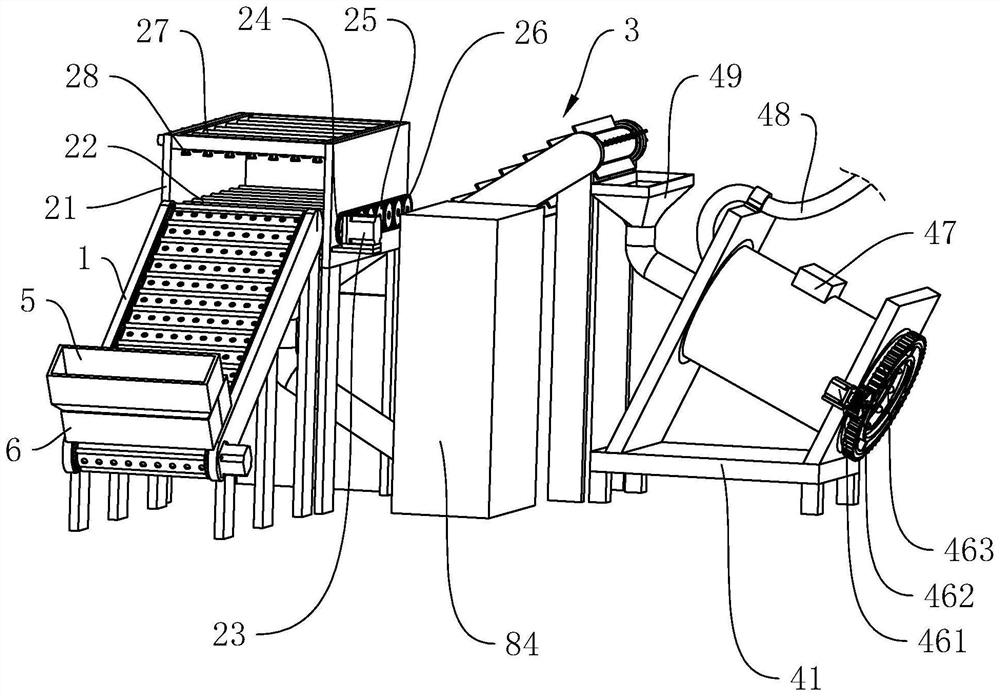

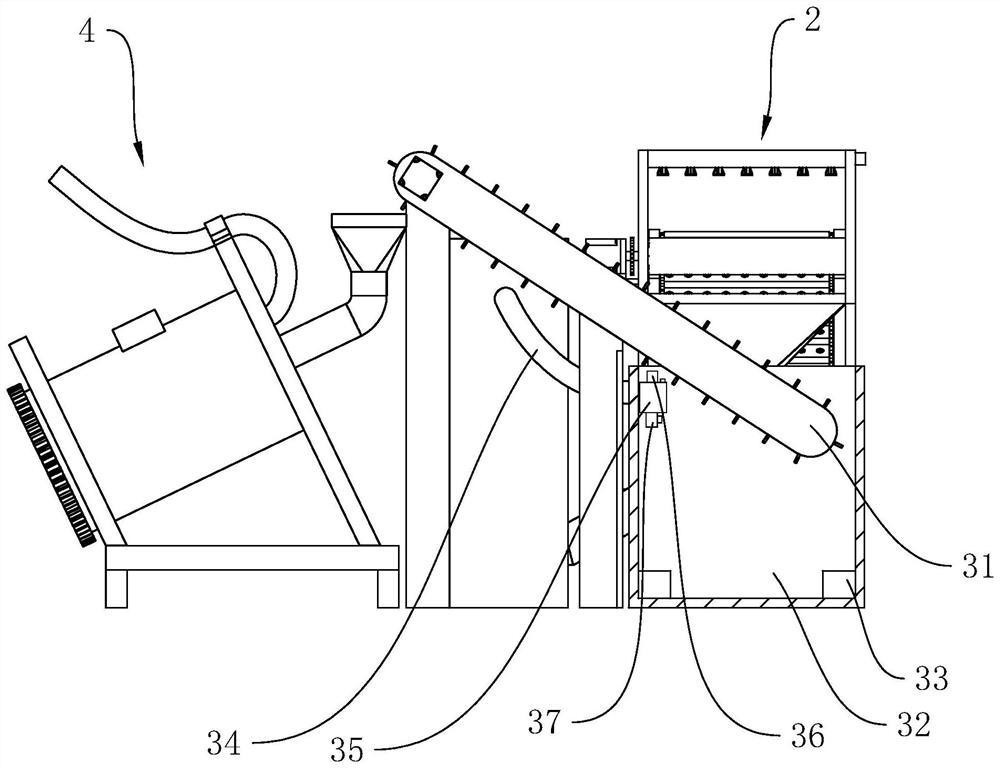

[0039] The following is attached Figure 1-4 The application is described in further detail.

[0040] The embodiment of the present application discloses an oyster cleaning system. refer to figure 1, an oyster cleaning system includes a feeding conveyor belt 1, the discharge end of the feeding conveyor belt 1 is provided with a primary cleaning mechanism 2, the primary cleaning mechanism 2 is used to initially clean the soil on the surface of the oyster, and the discharge end of the primary cleaning mechanism 2 is provided with The vibration cleaning mechanism 3 is used to vibrate and clean the oysters. The discharge end of the vibration cleaning mechanism 3 is provided with a drum cleaning mechanism 4, which is used for rolling cleaning the oysters. When working, put the oysters to be cleaned on the feeding conveyor belt 1, and transfer the oysters to the primary cleaning mechanism 2 through the feeding conveyor belt 1 for preliminary cleaning. The oysters are vibrated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com