Punching device capable of collecting waste materials and used for metal manufacturing and machining

A metal manufacturing and punching device technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of troublesome punch installation, poor positioning effect, easy damage, etc., to achieve convenient installation and disassembly, and convenient adjustment. , The effect of positioning plate stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

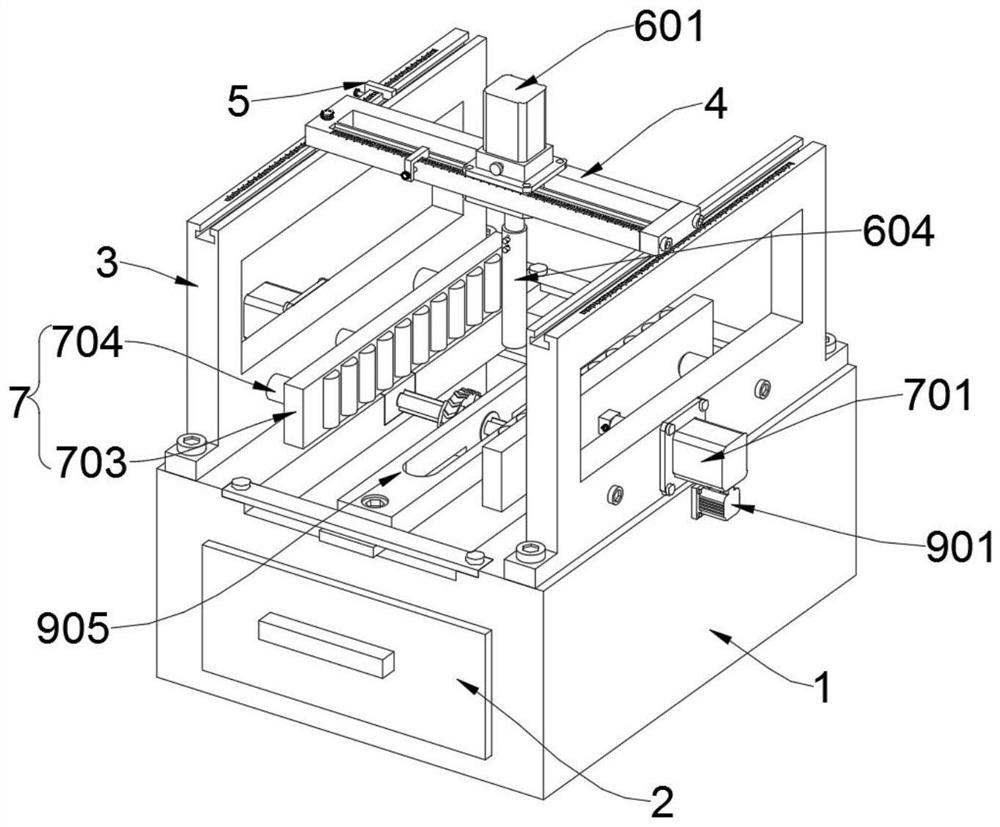

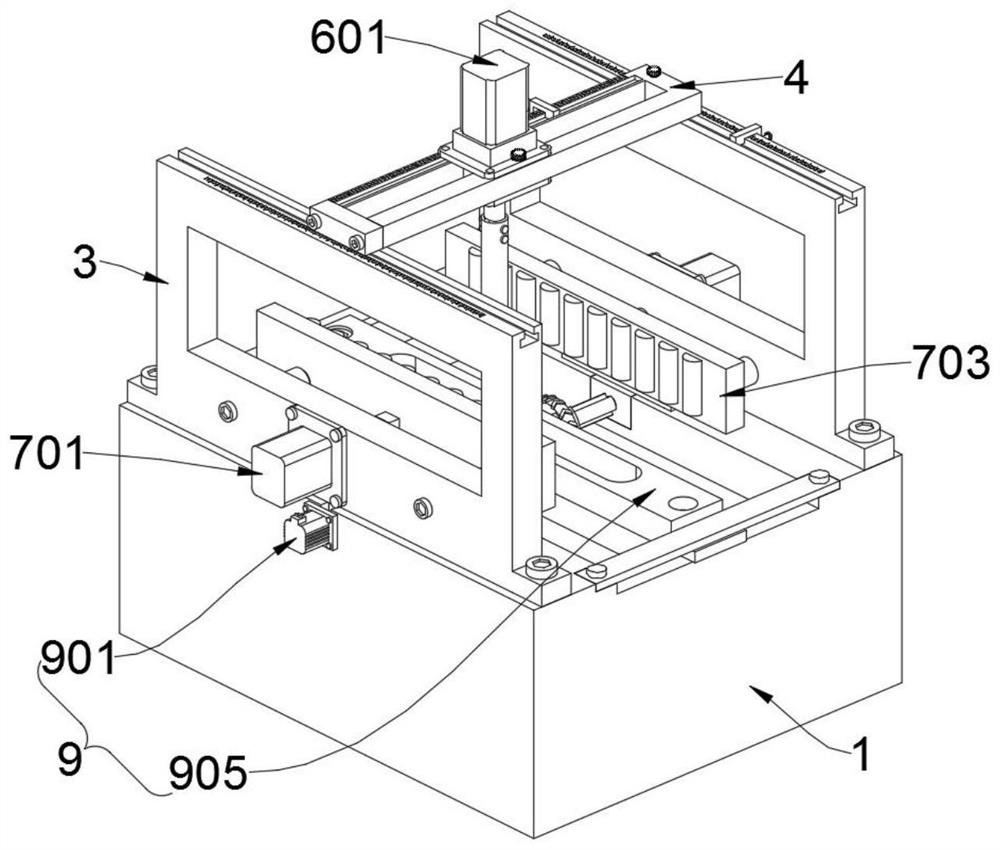

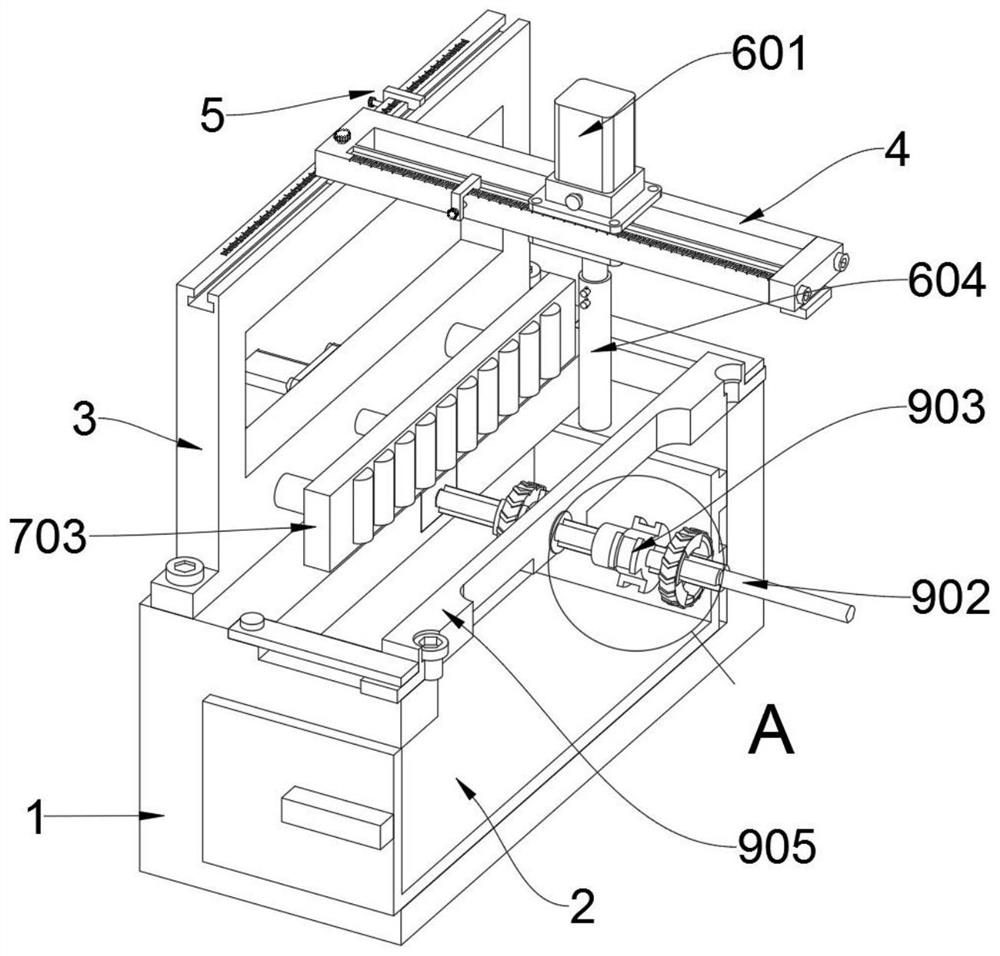

[0068] as attached figure 1 to attach Figure 13 Shown:

[0069] The invention provides a metal manufacturing and processing punching device capable of collecting scrap, including a protective structure;

[0070] A collection box 2 and a supporting vertical plate 3 are installed on the protective structure, and there are two supporting vertical plates 3, and the two supporting vertical plates 3 are symmetrically installed on the edge position above the protective structure through bolts, and the supporting vertical plate 3 is a rectangular structure. And the support vertical plate 3 is provided with a rectangular hole for reducing weight, and the bottom of the support vertical plate 3 is symmetrically provided with two connecting plates of rectangular structure, and a circular bolt mounting hole is provided on the connecting plate. There are rectangular slots matching the bottom of the support vertical board 3 symmetrically. When in use, the slots at the bottom of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com