Near-net forming method and device for multi-axis and axis variable zero component

A near-net-shaping, multi-axis technology, which is applied in the direction of grinding drive devices, processing drive devices, and parts of grinding machine tools, can solve problems such as the reduction of transmission and machining accuracy, the difficulty in realizing the inner wall of parts, and the seizure of worktables. , to achieve the effect of expanding the scope of work and business, improving production flexibility, and preventing high-temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

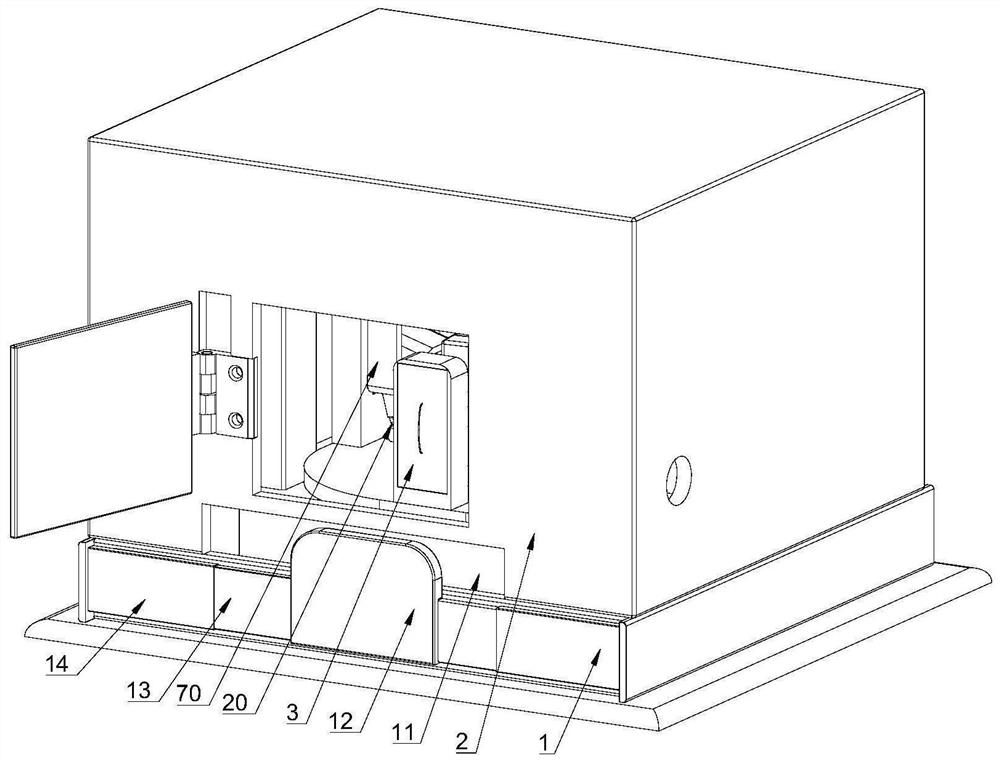

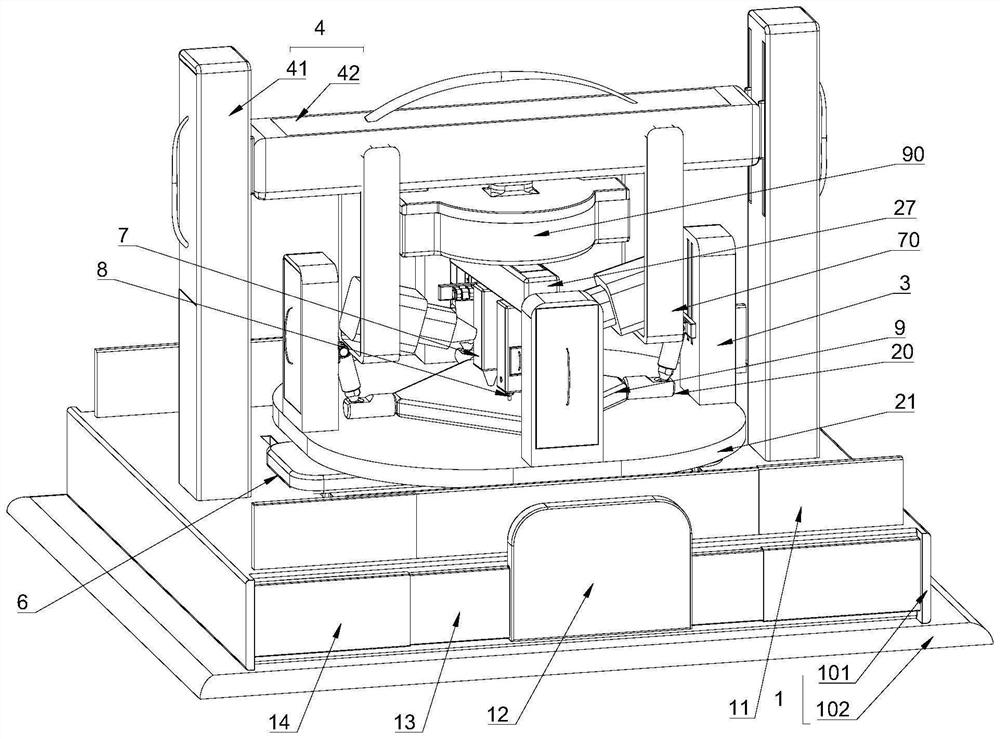

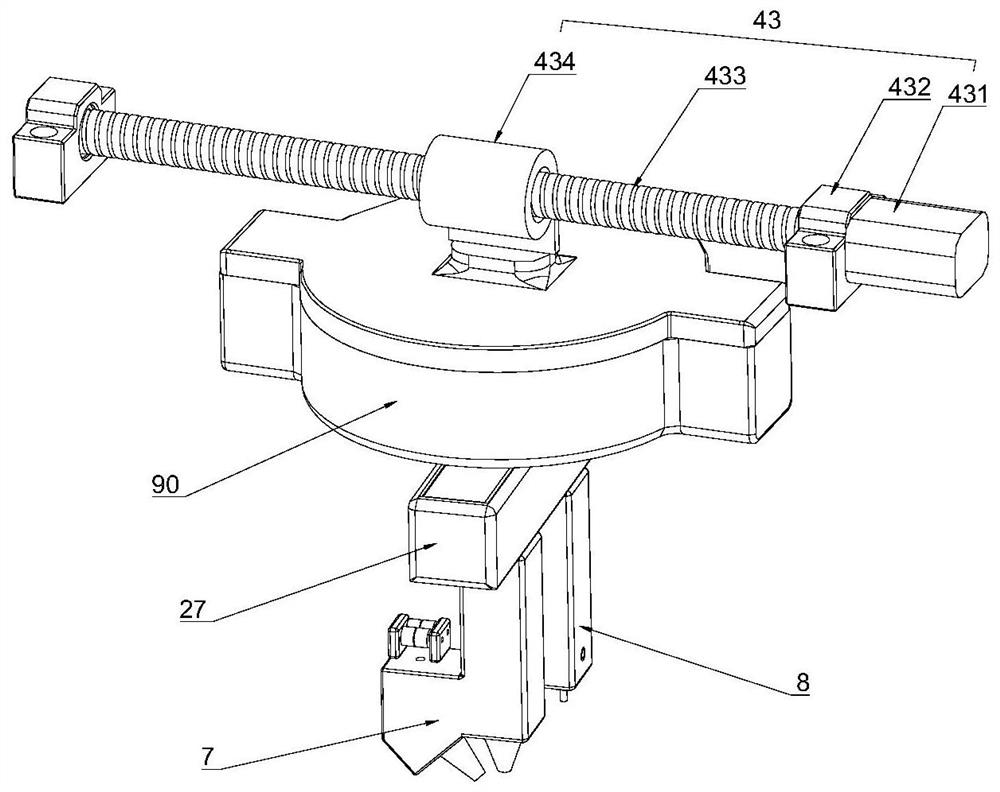

[0079] Such as Figures 1 to 35As shown, the near-net-shape device for multi-axis and variable axis zero components in this embodiment includes a fixed base 1, a first column 3, a gantry crane 4, an additive module 7, a composite mobile platform, a laser subtractive module 70, a grinding Cutting material module 8, workbench 9, first connector 20, linkage beam 27, rotating beam 90; gantry crane 4 includes gantry crane beam 41 and gantry crane column 42, gantry crane column 42 is located at both ends of gantry crane beam 41 and fixed on the fixed base 1 ; The gantry crane column 42 is provided with the first driving mechanism 17 for driving the gantry crane beam 41 to move up and down; Mechanism 16, the lower mobile platform 6 is connected to the bottom of the upper mobile platform 5 and can move horizontally relative to the fixed base 1 under the drive of the third drive mechanism 16, and the upper mobile platform 5 is relatively movable relative to the fixed base 1 under the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com