Pipe group construction process of efficient intelligent cold source system of central air conditioner

A technology of central air conditioning and construction technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of easy to eat dust, difficult to improve efficiency, laborious and other problems, and achieve easy operation, highly stable adjustment, and easy to carry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

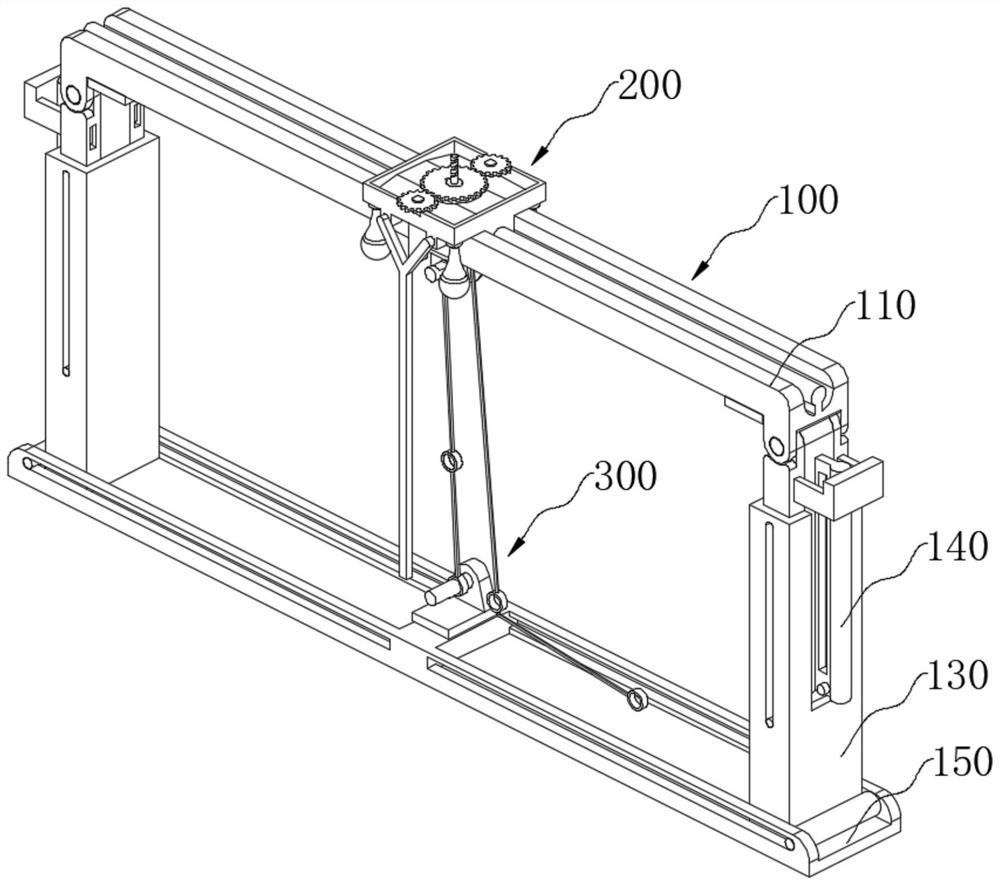

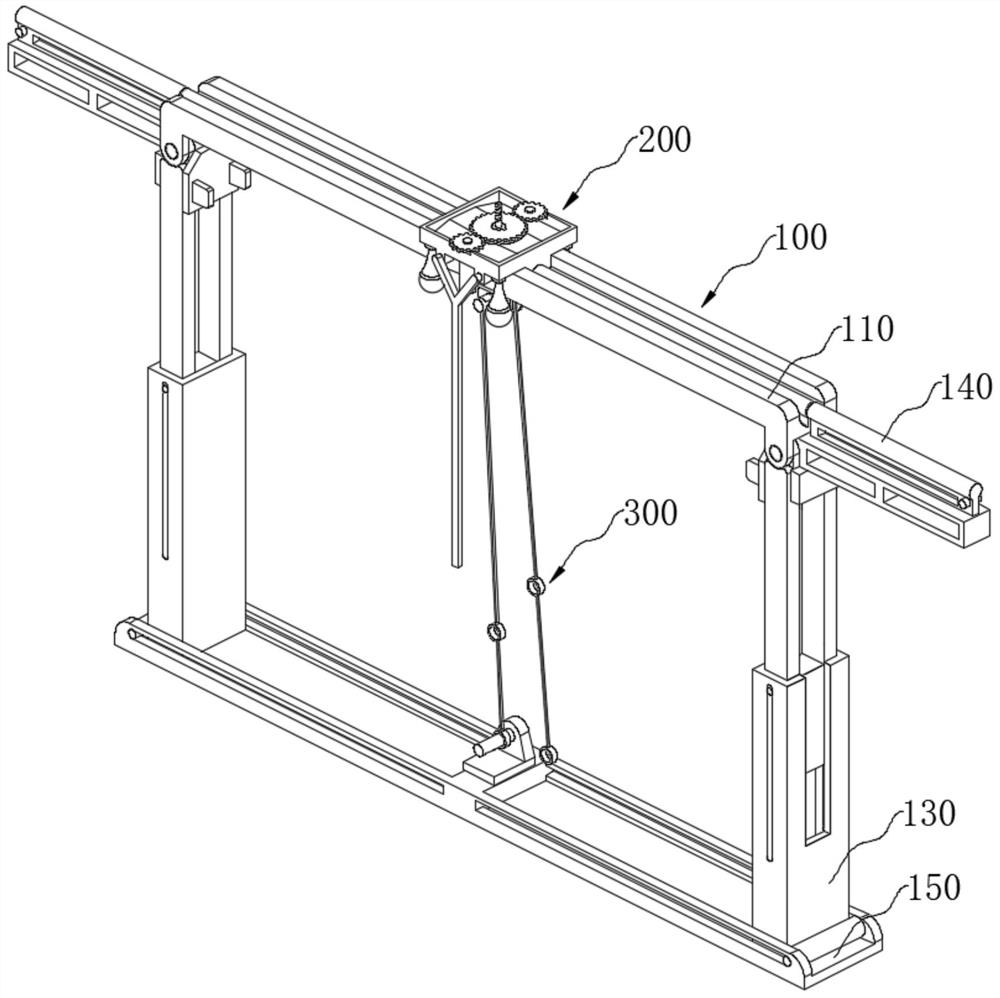

[0054] see Figure 1-Figure 15 As shown, the present invention provides a tube group construction process for a central air-conditioning high-efficiency intelligent cold source system, including the following steps:

[0055] 1. Preparatory stage before drilling:

[0056] S1. First move the construction device of the central air-conditioning tube group to the side of the wall, then untie the height adjustment device 300 and lift the track frame 110 to make the folded tube 130 turn from horizontal to vertical to increase the height of the track frame 110;

[0057] S2, then open the folding rail 140 and turn it to a horizontal state, which is used to extend the drilling range of the rail frame 110, and insert the slot piece 170 into the top of the strut 112 to limit the folding rail 140 and keep the folding rail 140 spread out horizontally;

[0058] Second, the punching stage:

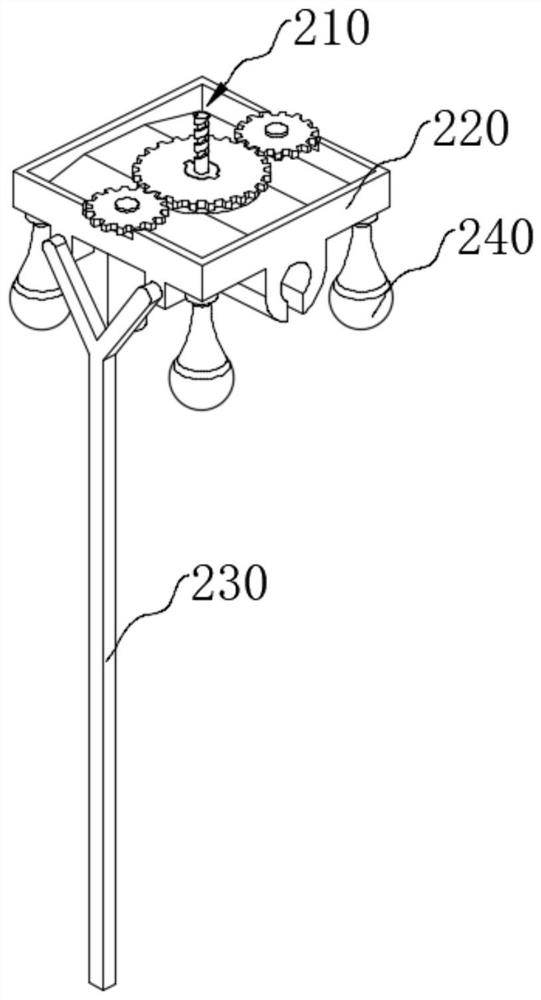

[0059] S3. Move the ash collecting table 220 to one of the folding rails 140, and start the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com