Novel automatic tensioning electric control system for monitoring scraper conveyor chain

An electronic control system and scraper machine technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problem of inability to elongate the conveyor chain or compensate for tension, decrease the tension of the conveyor chain, and scraper conveying Problems such as machine jams and chains, to achieve good shock absorption and buffering effects, reduce fluctuations and impacts, and ensure stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

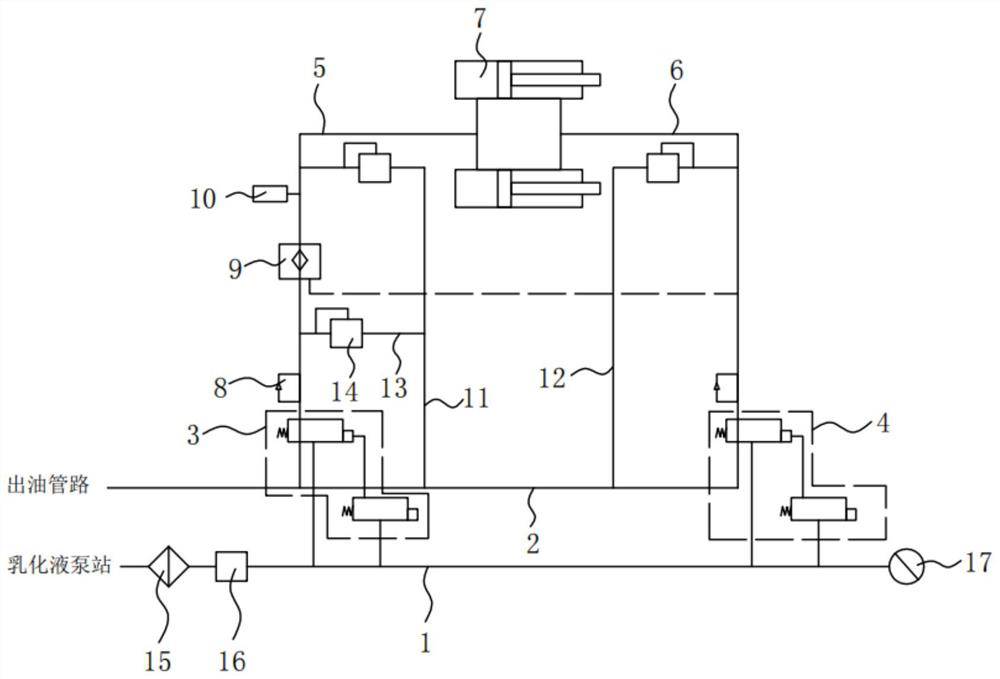

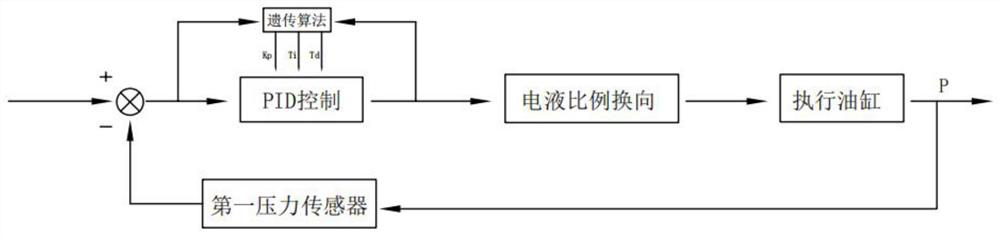

[0028] Please refer to figure 1 , figure 2 ,in, figure 1 Schematic diagram of the structure of the first embodiment of the new monitoring automatic tensioning electric control system for scraper chains provided by the present invention; figure 2 The schematic diagram of PID optimization control based on genetic algorithm for the new monitoring automatic tensioning electric control system of scraper machine chain provided by the present invention. The new electronic control system for monitoring the automatic tensioning of the scraper chain includes: the first pipeline 1 connected to the emulsion pump station and the second pipeline 2 connected to the oil outlet pipeline;

[0029] The first pipeline 1 communicates with the second pipeline 2, a control valve 3 and a recovery valve 4 are arranged between the first pipeline 1 and the second pipeline 2, and the second pipeline 2 communicates with the second pipeline 2. The third pipeline 5 and the fourth pipeline 6, the execut...

no. 2 example

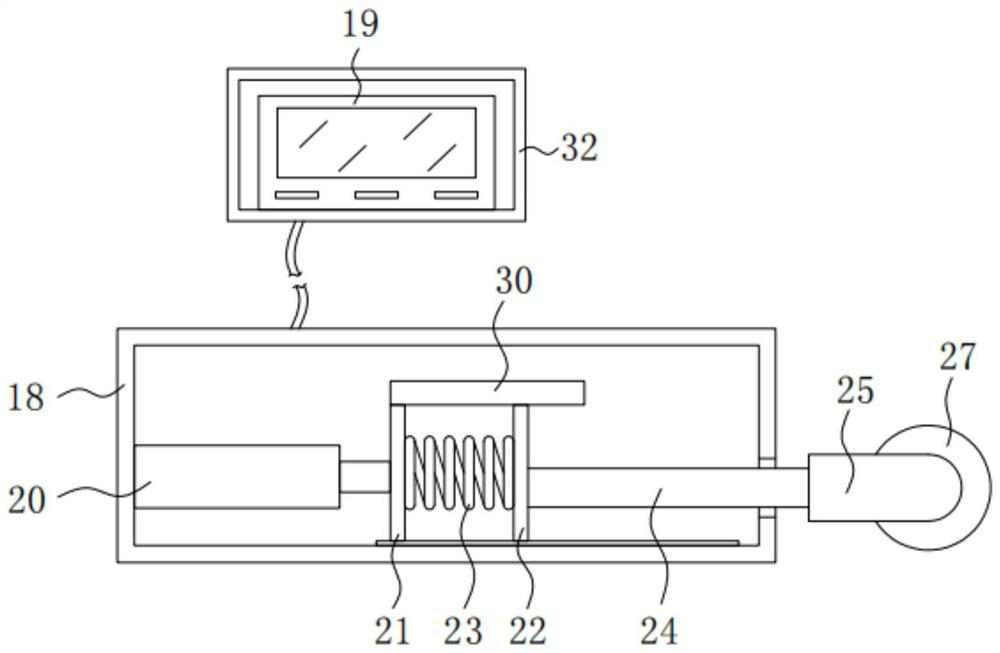

[0036] Please refer to Figure 3-Figure 4, based on the new monitoring electronic control system for automatic tensioning of scraper machine chains provided in the first embodiment of the present application, the second embodiment of the present application proposes another new type of electronic control system for monitoring automatic tensioning of scraper machine chains. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0037] Specifically, the new electronic control system for monitoring the automatic tensioning of scraper machine chains provided by the second embodiment of the present application is different in that it also includes a detection device for testing the tension degree of scraper machine chains. The detection device includes an installation frame 18 and a display 19, the left side of the inner wall of the installation...

no. 3 example

[0046] Please refer to Figure 5 , based on the new monitoring electronic control system for automatic tensioning of scraper machine chains provided in the first embodiment of the present application, the third embodiment of the present application proposes another new type of electronic control system for monitoring automatic tensioning of scraper machine chains. The third embodiment is only a preferred mode of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0047] Specifically, the difference of the new electronic control system for monitoring the automatic tensioning of scraper machine chain provided by the third embodiment of the present application is that it also includes a preheating device, and the preheating device includes a box body 33, and the box body 33 is set on the pipeline of the first pipeline 1, the inside of the box 33 is provided with an electric heating plate 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com