Multifunctional filling vertical pipe for fluid tank car butt joint

A multi-functional, vertical tube technology, applied in liquid distribution, conveying or transfer devices, packaging, transportation and packaging, etc., to achieve the effect of solving sealing requirements, solving scraping problems, fast matching and docking installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

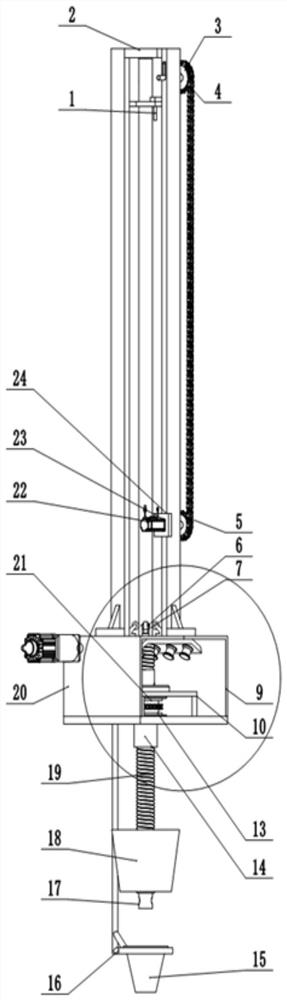

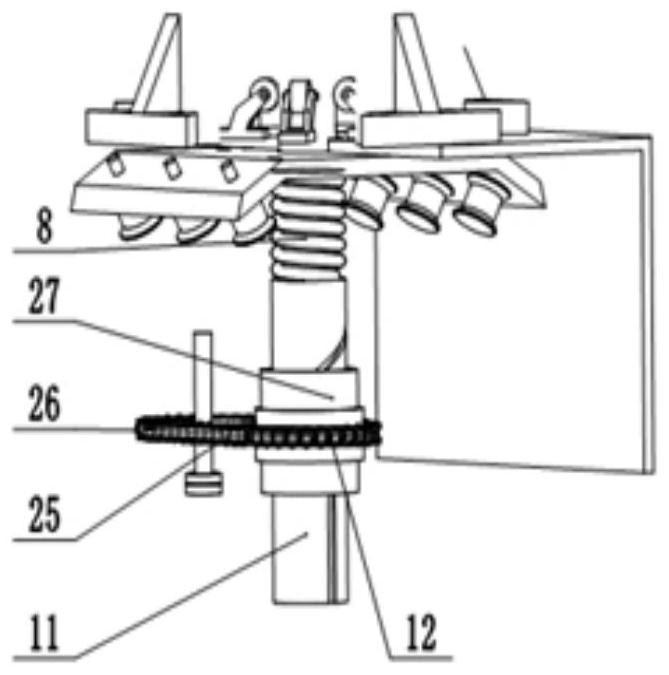

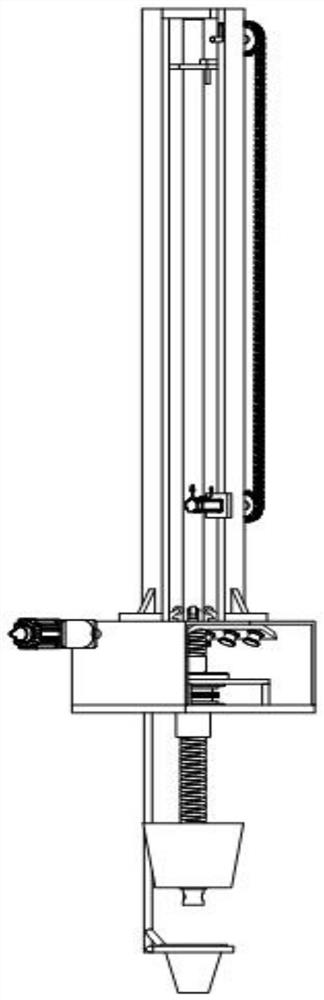

[0038] Such as figure 1 , figure 2 As shown, this embodiment discloses a multifunctional filling drop pipe for docking of a fluid tanker, including a drop pipe 17 and a liquid holding bucket 15, and is characterized in that it includes a frame, a power drive mechanism, a rotating mechanism, a transmission member and a mounting The scraper liquid holding mechanism on the vertical pipe;

[0039] Wherein the frame includes chain and vertical pipe mounting seat 1, chain and vertical pipe mounting frame 2, vertical pipe pressing wheel base 7, external fixed support part one 9, external fixed support part two 20, reducer mounting seat 24;

[0040] The power drive mechanism includes a servo motor 22 and a reducer 23, wherein the servo motor 22 and the reducer 23 are installed on the reducer mount 24 on the chain and vertical pipe installation frame 2 to provide power for the whole system;

[0041] The rotating mechanism includes an outer spiral track moving part 11, a rotating gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com