Perforation well completion method for improving productivity of medium-high permeability oil and gas reservoir

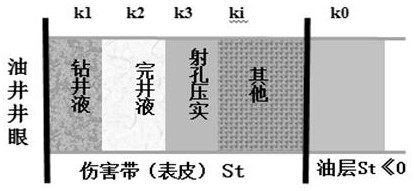

A technology for oil reservoirs and perforating charges, which is used in earth-moving drilling, wellbore/well components, and production fluids. The problems of limited pore volume and crushing zone treatment range can improve the conductivity and flow efficiency, reduce the pressure drop funnel near the wellbore, and improve the energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The perforation completion method includes: matching and loading shaped charges, high-energy particles and ignition devices in the perforating gun according to the optimized perforation density, and the installation quantity ratio of perforating charges and high-energy particles is 1:1;

[0040] The deep-penetrating perforating bullet is used to implement energy-concentrating perforation on the casing, cement sheath and formation of the target reservoir, and the ignition device is used to realize the internal ignition of the perforating gun.

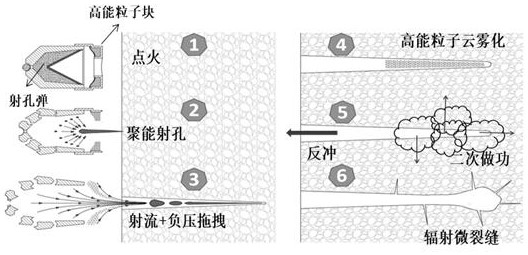

[0041] After ignition, the specific reaction process is as follows figure 1 Shown:

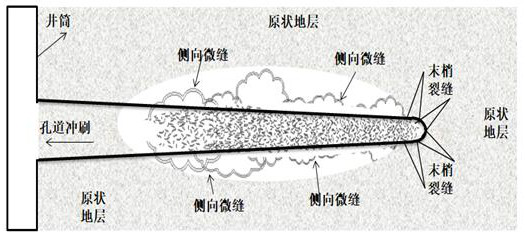

[0042]The internal ignition of the perforating gun is realized by the ignition device, and the energy-shaping perforating bullets are formed through high-temperature and high-pressure metal jets extruding the formation to form channels to start energy-enhancing perforation; the high-pressure metal jet extrudes the formation to complete the energy-...

Embodiment 2

[0052] Taking two wells F-1 and F-2 in the same layer in the rectangular (well spacing: row spacing = 2:1) drainage area of a medium permeability oil reservoir as an example, the original formation pressure of the block is 27.8MPa, and the drainage The radius is 80m, the wellbore radius is 0.1m, the viscosity of formation crude oil is 5mPa.s, the volume coefficient of formation crude oil is 1.2, and the corresponding coefficient of drainage shape is 0.668. Well F-1 reservoir is buried at a depth of 2810m, and the reservoir permeability is 52×10 -3 μm 2 , the thickness of the oil layer is 14.5m; the middle depth of the reservoir of F-2 well is 2785m, and the permeability of the oil layer is 57×10 -3 μm 2 , the oil layer thickness is 15.6m. Well F-1 adopts the perforation completion method described in Example 1 of the present invention, with a perforation thickness of 14.5m and a perforation density of 16 holes / m. Hole completion method, perforation thickness 15.6m, perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com