Waterproof anchoring structure

An anchoring and structural technology, applied in the direction of installation of anchor rods, shaft equipment, wellbore lining, etc., can solve the problems of affecting the stability of geotextile sticking, affecting the stability of sticking, and detachment of geotextiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

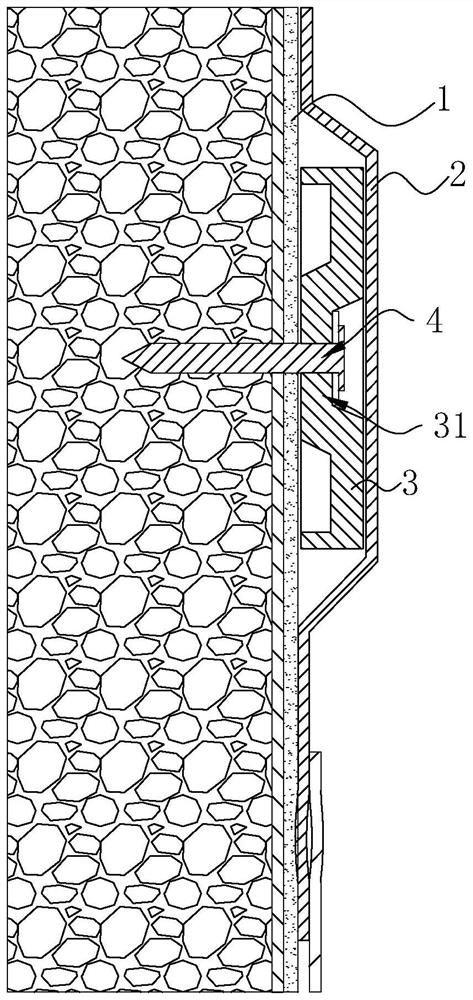

[0037] refer to figure 1 The waterproof anchoring structure includes a geotextile 1 and a waterproof board 2 sequentially arranged from the inner wall of the tunnel outward, and a plurality of geotextiles 1 and waterproof boards 2 are provided and cover the inner wall of the tunnel. The geotextile 1 is pierced with an anchor component for fixing it to the inner wall of the tunnel.

[0038] The anchor assembly includes a backing plate 3 and an anchor 4 arranged between the geotextile 1 and the waterproof board 2. The anchor 4 is penetrated through the geotextile 1 and inserted into the inner wall of the tunnel, so as to connect the geotextile 1 and the backing plate 3 Fixed connection to the inner wall of the tunnel.

[0039] Specifically, the backing plate 3 is made of hot-melt sealing material, such as EVA plastic, HDPE and other hot-melt plastics. The middle part of the backing plate 3 is recessed toward the inner wall of the tunnel to form a recessed part 31 , the recesse...

Embodiment 2

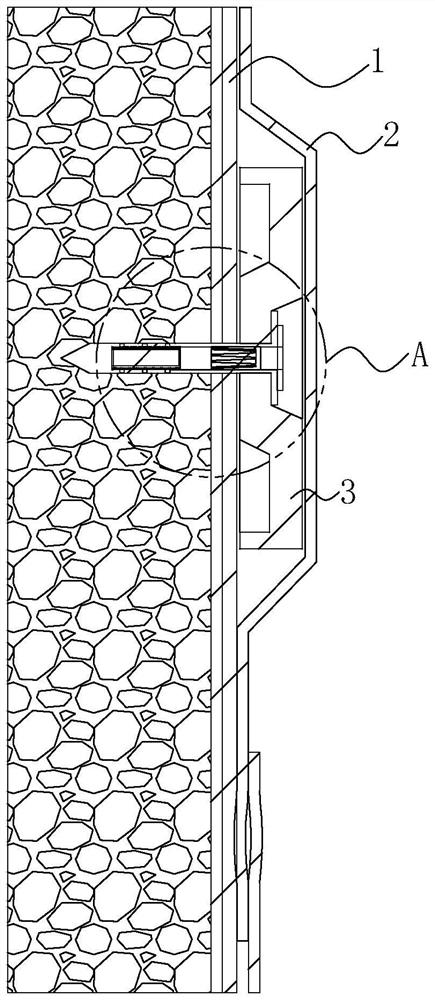

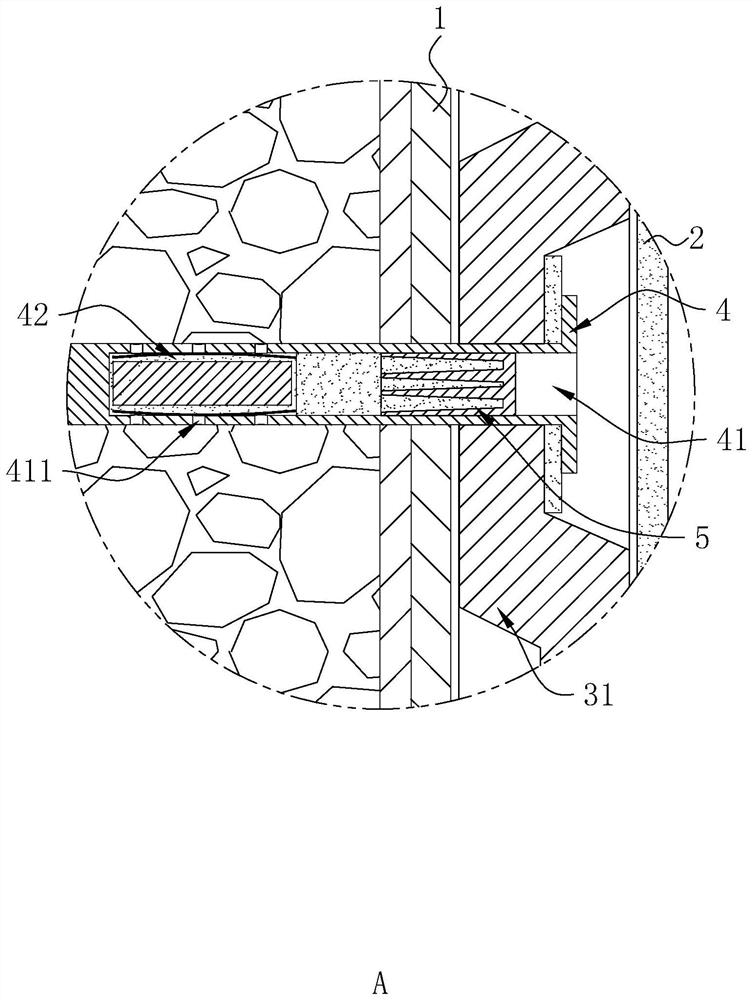

[0044] refer to figure 2 and image 3 The difference between this embodiment and Embodiment 1 is that the anchor 4 has a rod-shaped structure, and one end of the anchor 4 inserted into the inner wall of the tunnel has a tapered structure, and the end of the anchor 4 located outside the inner wall of the tunnel is T-shaped. And the big end is pressed into the concave portion 31 of the backing plate 3 .

[0045] An anchoring hole 41 extending along the length direction of the anchoring piece 4 is provided inside, and one end of the anchoring hole 41 facing the outer side of the inner wall of the tunnel is opened. An adhesive box 42 is disposed in the anchor hole 41 , and the inside of the adhesive box 42 is hollow and filled with compressed temperature-resistant structural glue. Wherein, the anchor hole 41 is also provided with an extrusion component 5 that extrudes the structural glue in the adhesive box body 42 when heated. The extrusion component 5 is located on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com