Double-tower double-circulation in-vitro oxidation efficient desulfurization and dust removal integrated device

A desulfurization and dust removal, double-cycle technology, applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, can solve the problems of short residence time of flue gas, imperfect technology, cumbersome maintenance, etc., and achieve the increase of oxidation reaction time and the use of Effect of range extension, flow rate control reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

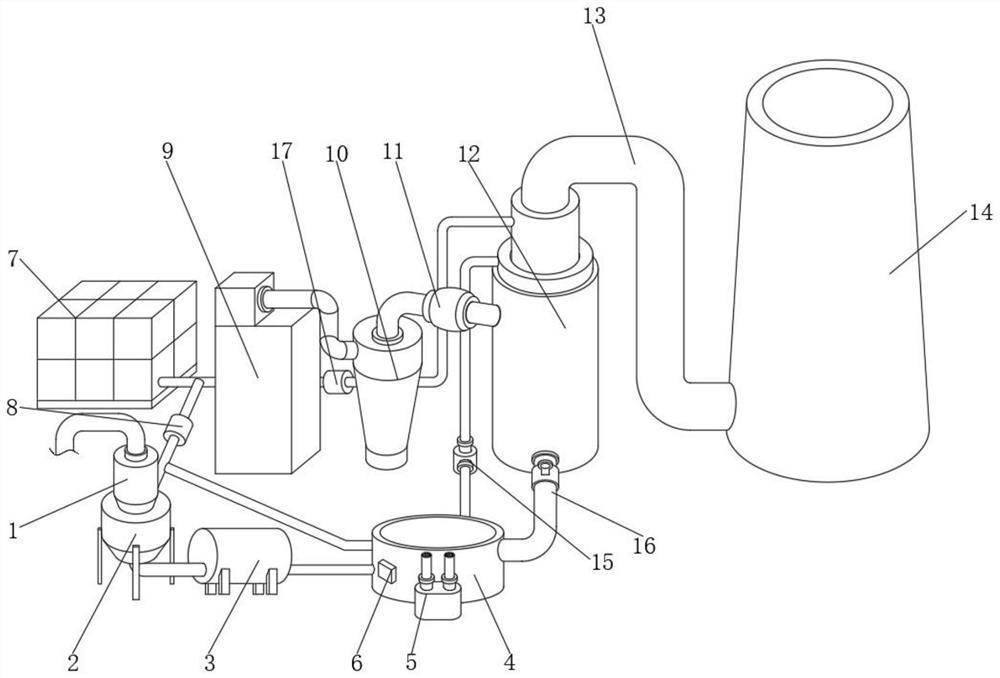

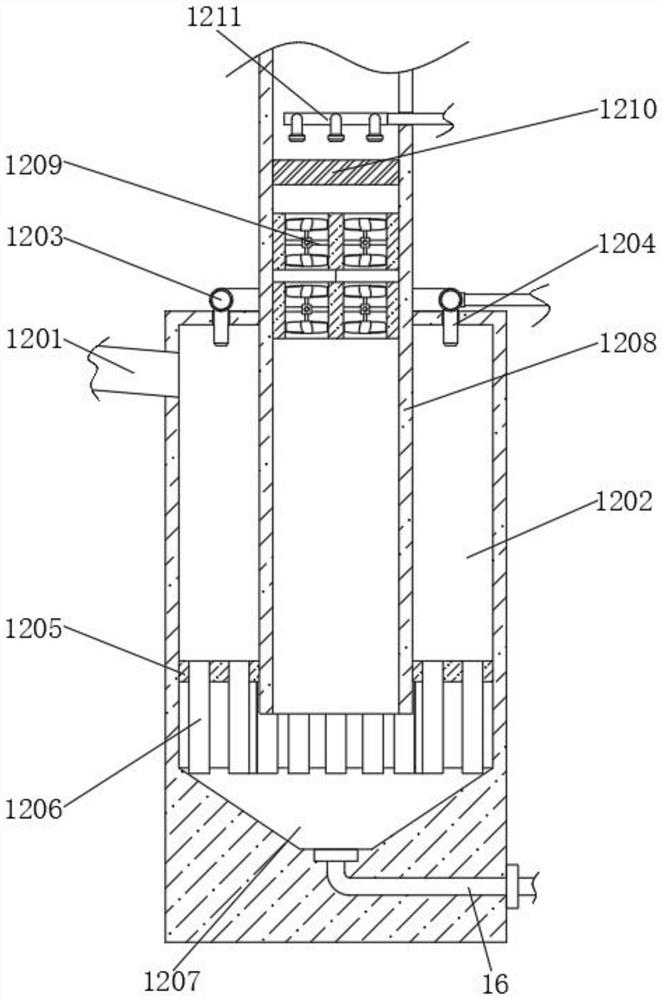

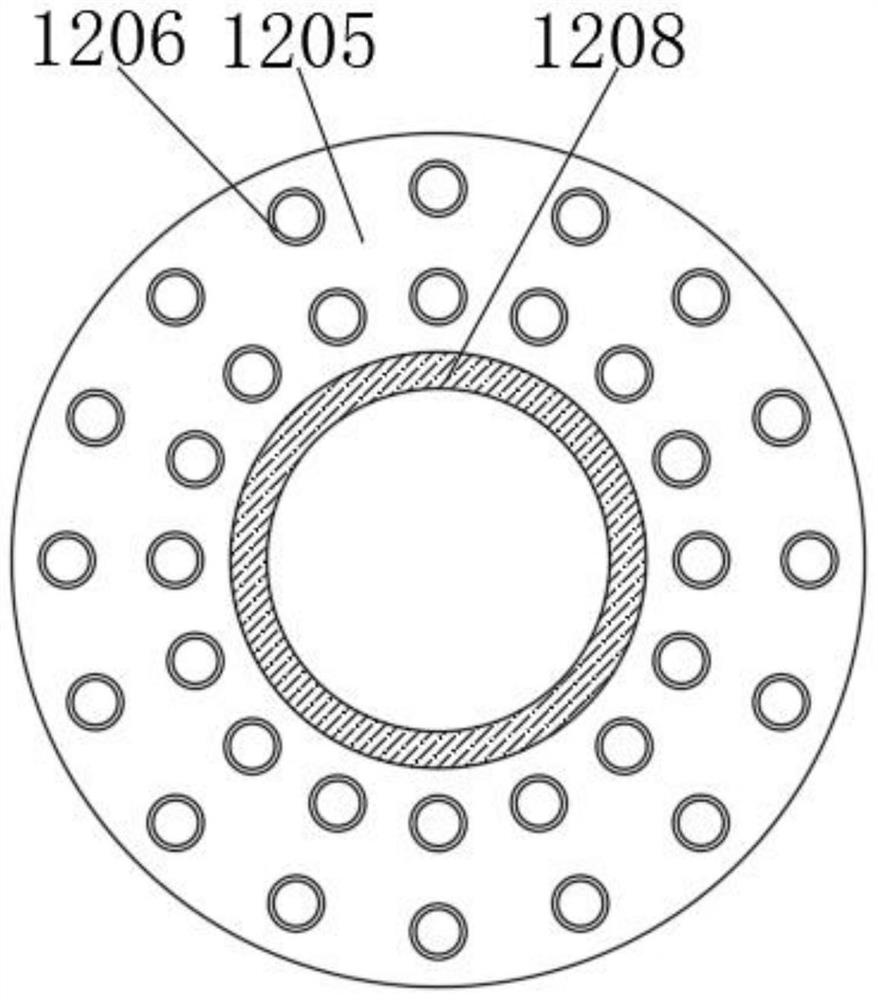

[0032] see Figure 1-4, the present invention provides a technical solution: an integrated device for high-efficiency desulfurization and dust removal of extracorporeal oxidation with double towers and double cycles, including a raw material powder silo 1, a pulping machine 2, a slurry tank 3, a circulating water pool 4, an oxidation fan 5, a density test pump 6, and a water tank 7. Water supply pump 8, boiler main body 9, dust collector 10, induced draft fan 11, main frame 12, air inlet 1201, flue gas pretreatment chamber 1202, annular pipe 1203, nozzle 1204, connecting frame 1205, strengthening channel 1206, slurry pool 1207, inner tower frame 1208, swirl 1209, louver 1210, flushing sprinkler head 1211, air outlet pipe 13, chimney 14, circulation pump 15, discharge pipe 16 and flushing pump 17, raw material powder silo 1 is connected There is a pulping machine 2, and a slurry tank 3 is installed on the pulping machine 2, a circulating water tank 4 is connected to the slurry ...

Embodiment 2

[0036] The working process of the integrated device for high-efficiency desulfurization and dedusting of double-tower and double-circulation extracorporeal oxidation includes the following steps in sequence:

[0037] (A) First, the material in the raw material powder silo 1 is transported to the pulper 2 through the feeder, and at the same time, the water in the water tank 7 is injected into the pulper 2, and then the pulper 2 is started to prepare slurry , the prepared slurry is discharged into the slurry tank 3 and waits for standby, and the slurry raw material adopted is calcium hydroxide or sodium hydroxide or magnesium oxide or liquefied ammonia;

[0038] (B) Next, the flue gas discharged from the boiler is subjected to preliminary dust removal treatment through the dust collector 10, and the treated flue gas enters the inside of the flue gas pretreatment chamber 1202 from the top of the outer tower to the tangential direction through the induced draft fan 11 at a correspo...

Embodiment 3

[0045] The working process of the integrated device for high-efficiency desulfurization and dedusting of double-tower and double-circulation extracorporeal oxidation includes the following steps in sequence:

[0046] (A) First, the material in the raw material powder silo 1 is transported to the pulper 2 through the feeder, and at the same time, the water in the water tank 7 is injected into the pulper 2, and then the pulper 2 is started to prepare slurry , the prepared slurry is discharged into the slurry tank 3 and waits for standby, and the slurry raw material adopted is calcium hydroxide or sodium hydroxide or magnesium oxide or liquefied ammonia;

[0047] (B) Next, the flue gas discharged from the boiler is subjected to preliminary dust removal treatment through the dust collector 10, and the treated flue gas enters the inside of the flue gas pretreatment chamber 1202 from the top of the outer tower to the tangential direction through the induced draft fan 11 at a correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com