Gas-liquid two-phase power type separated heat pipe device

A separate heat pipe, gas-liquid separator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as bulky, expensive engineering, and difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

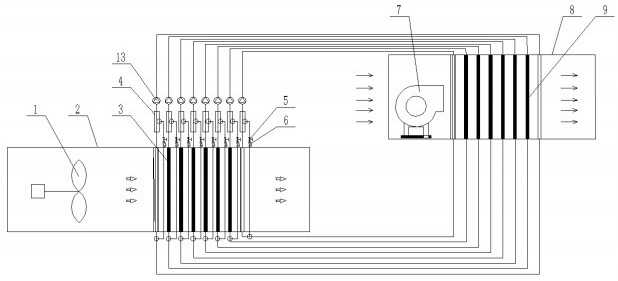

Embodiment 1

[0030] according to figure 1 As shown, a liquid separation circuit is connected to the heat pipe, and the liquid separation circuit includes a gas-liquid separator a4, and the gas-liquid separator a4 is installed on the gas path between the heat pipe evaporation end 3 and the heat pipe condensation end 9; on the gas-liquid separator a4 There is a pipeline a connected, and the end of the pipeline a is connected to the liquid path between the evaporating end 3 of the heat pipe and the condensing end 9 of the heat pipe; the valve group a5 and the check valve a6 are installed on the pipeline a, and the valve group a5 is located at the check valve Between a6 and gas-liquid separator a4. The pumping device is an air pump 13 installed on the air path of the heat pipe, and the gas-liquid separator a4 is located between the air pump 13 and the evaporation end 3 of the heat pipe.

[0031] Working fluid circulation mode:

[0032] The liquid working medium absorbs heat at the evaporatin...

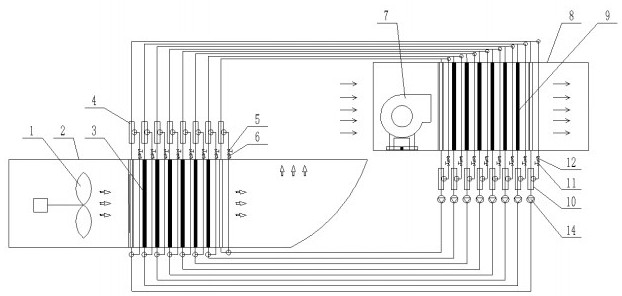

Embodiment 2

[0034] according to figure 2 As shown, a liquid separation circuit is connected to the heat pipe, and the liquid separation circuit includes a gas-liquid separator a4, and the gas-liquid separator a4 is installed on the gas path between the heat pipe evaporation end 3 and the heat pipe condensation end 9; on the gas-liquid separator a4 There is a pipeline a connected, and the end of the pipeline a is connected to the liquid path between the evaporating end 3 of the heat pipe and the condensing end 9 of the heat pipe; the valve group a5 and the check valve a6 are installed on the pipeline a, and the valve group a5 is located at the check valve Between a6 and gas-liquid separator a4. At the same time, a gas separation circuit is connected to the heat pipe, and the gas separation circuit includes a gas-liquid separator b10, which is installed on the liquid path; a pipeline b is connected to the gas-liquid separator b10, and the end of the pipeline b is connected to the gas On t...

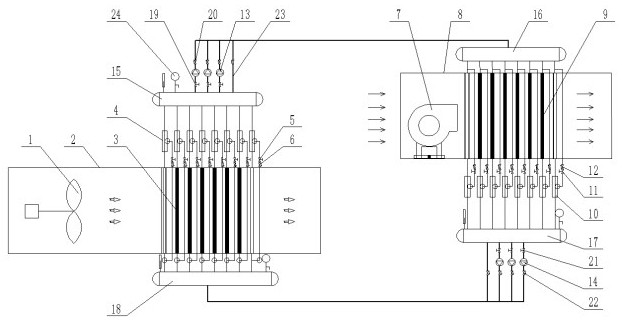

Embodiment 3

[0038] according to image 3 As shown, a liquid separation circuit is connected to the heat pipe, and the liquid separation circuit includes a gas-liquid separator a4, and the gas-liquid separator a4 is installed on the gas path between the heat pipe evaporation end 3 and the heat pipe condensation end 9; on the gas-liquid separator a4 There is a pipeline a connected, and the end of the pipeline a is connected to the liquid path between the evaporating end 3 of the heat pipe and the condensing end 9 of the heat pipe; the valve group a5 and the check valve a6 are installed on the pipeline a, and the valve group a5 is located at the check valve Between a6 and gas-liquid separator a4. At the same time, a gas separation circuit is connected to the heat pipe, and the gas separation circuit includes a gas-liquid separator b10, which is installed on the liquid path; a pipeline b is connected to the gas-liquid separator b10, and the end of the pipeline b is connected to the gas On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com