Dynamic pressure air bearing test platform

A technology of air bearing and test platform, used in mechanical bearing testing, measuring device, electromagnetic measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

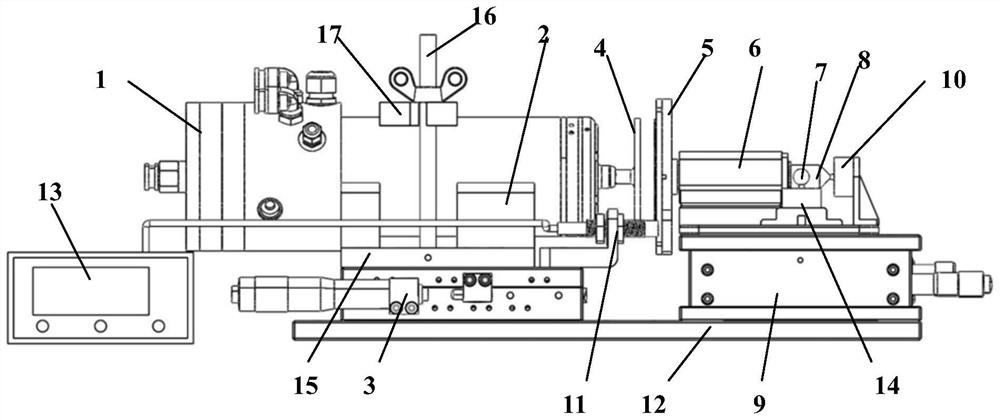

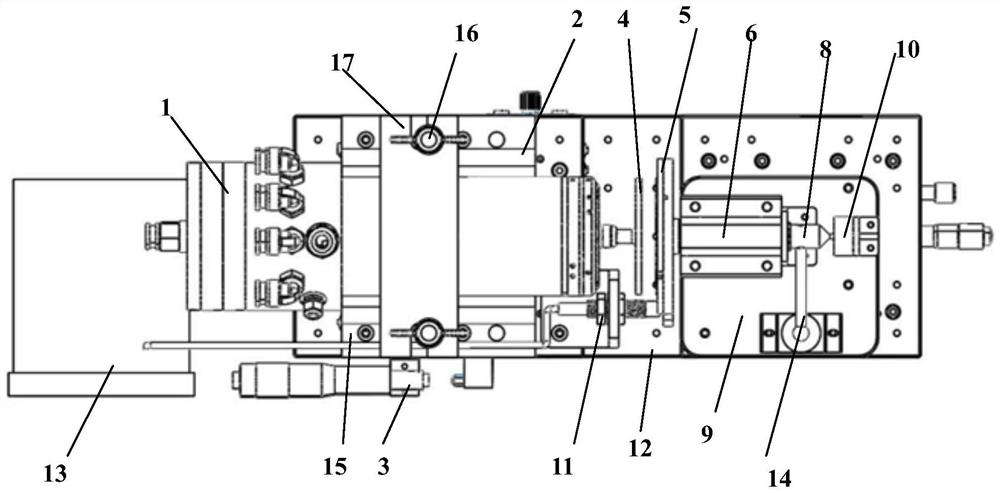

[0036] see figure 1 , a dynamic pressure air bearing test platform, including a platform body 12, an X-axis fine-tuning mobile platform 3, a Z-axis fine-tuning lifting platform 9, a thrust plate 4, a data display instrument 13 and a bearing fixing seat 5. The platform body 12 is a high-precision optical flat plate.

[0037] The X-axis fine-tuning mobile platform 3 and the Z-axis fine-tuning lifting platform 9 are respectively fixed on the left and right sides of the platform body 12 . A high-speed motor 1 with adjustable speed and a non-contact measuring eddy current sensor 11 are fixed on the X-axis precision fine-tuning mobile platform 3; the power output shaft of the high-speed motor 1 is connected with the thrust disc 4; the non-contact measuring eddy current sensor 11 is fixed on the X through a fixed block. The X-axis precision fine-tuning mobile platform 3 is used to measure the thickness of the air film. Before the test, adjust the X-axis precision fine-tuning mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com