Shale gas exploration sampling device for micro-grid power generation

A sampling device and shale gas technology, applied in the direction of sampling devices, etc., can solve problems such as inability to subpackage and sample soil layers at different depths, poor accuracy of exploration results, and users cannot quickly know the distribution of shale gas, so as to improve Accuracy, convenient distribution, easy mining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

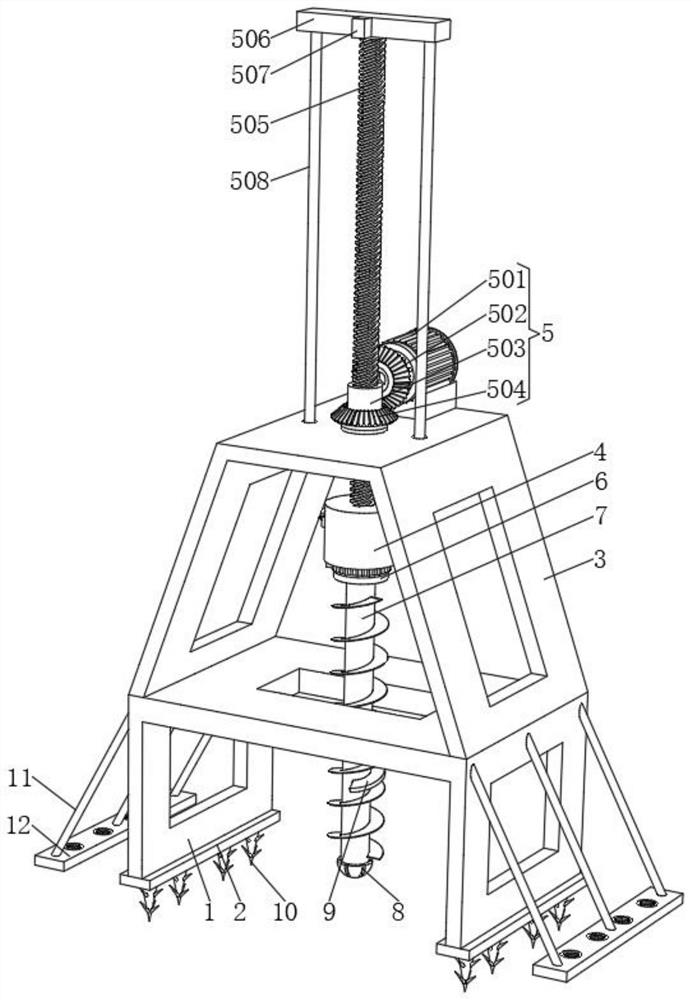

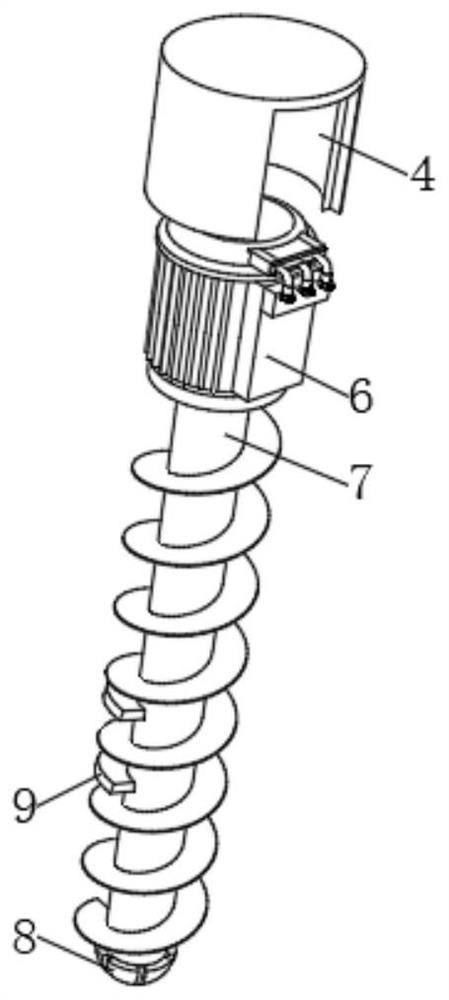

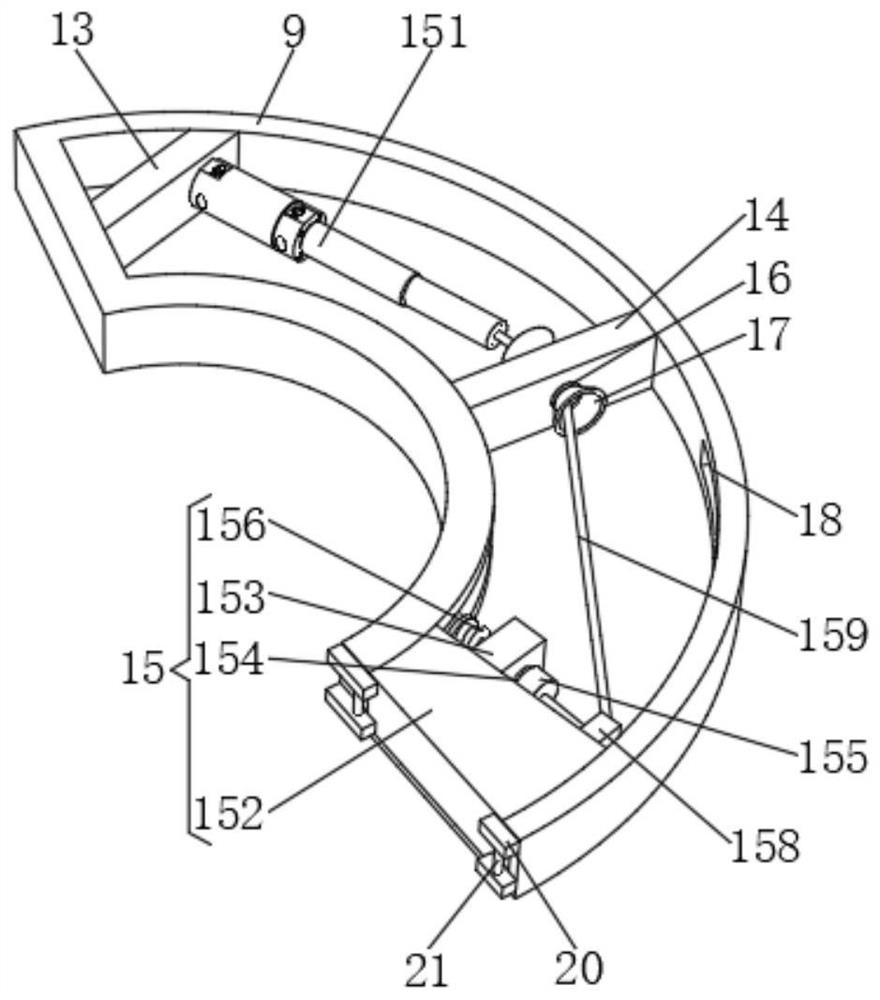

[0033] Such as Figure 1-6 A shale gas exploration and sampling device for microgrid power generation is shown, including a fixed frame 1 and a fixed sleeve 4, both sides of the bottom of the fixed frame 1 are fixedly connected with a bottom plate 2, and the bottom of the bottom plate 2 is fixedly connected with a Multiple sets of auxiliary ground nails 10, the design of multiple sets of auxiliary ground nails 10 improves the fixing effect between the bottom plate 2 and the ground, and further improves the overall stability of the device.

[0034] The support frame 3 is fixedly connected to the fixed frame 1, and the tops on both sides of the fixed frame 1 are fixedly connected with multiple sets of steel wire ropes 11 along the front and rear directions. The end of the steel wire ropes 11 away from the fixed frame 1 is fixedly connected with a pressing plate 12, and the upper edge of the pressing plate 12 is connected to the front and rear. There are multiple sets of locking ...

Embodiment 2

[0042] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, a shale gas exploration and sampling device for microgrid power generation includes a fixed frame 1 and a fixed sleeve 4, both sides of the bottom of the fixed frame 1 are fixedly connected with a bottom plate 2, and the bottom of the bottom plate 2 is fixedly connected with a Multiple sets of auxiliary ground nails 10, the design of multiple sets of auxiliary ground nails 10 improves the fixing effect between the bottom plate 2 and the ground, and further improves the overall stability of the device. The support frame 3 is fixedly connected to the fixing frame 1, and the fixing frame 1 The tops on both sides are fixedly connected with multiple sets of steel wire ropes 11 along the front and rear direction, and the end of the steel wire rope 11 away from the fixed frame 1 is fixedly connected with a pressing plate 12, and multiple sets of locking holes are embedded in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com