Experimental device and method for repairing film bag concrete cracks through vacuum grouting

An experimental device and concrete technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of affecting the durability of the project, the inaccessibility of the slurry, and the damage of the project, so as to reduce the difficulty of implementation, ensure the airtightness, and speed up the progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

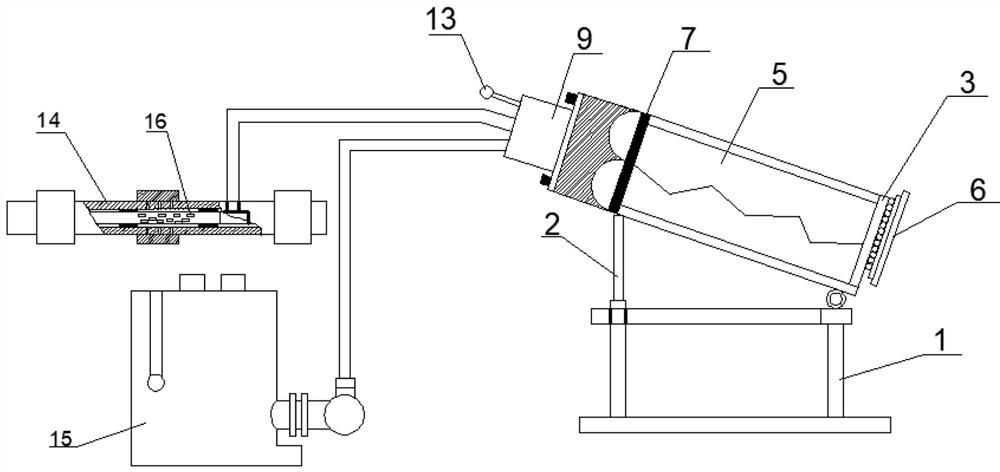

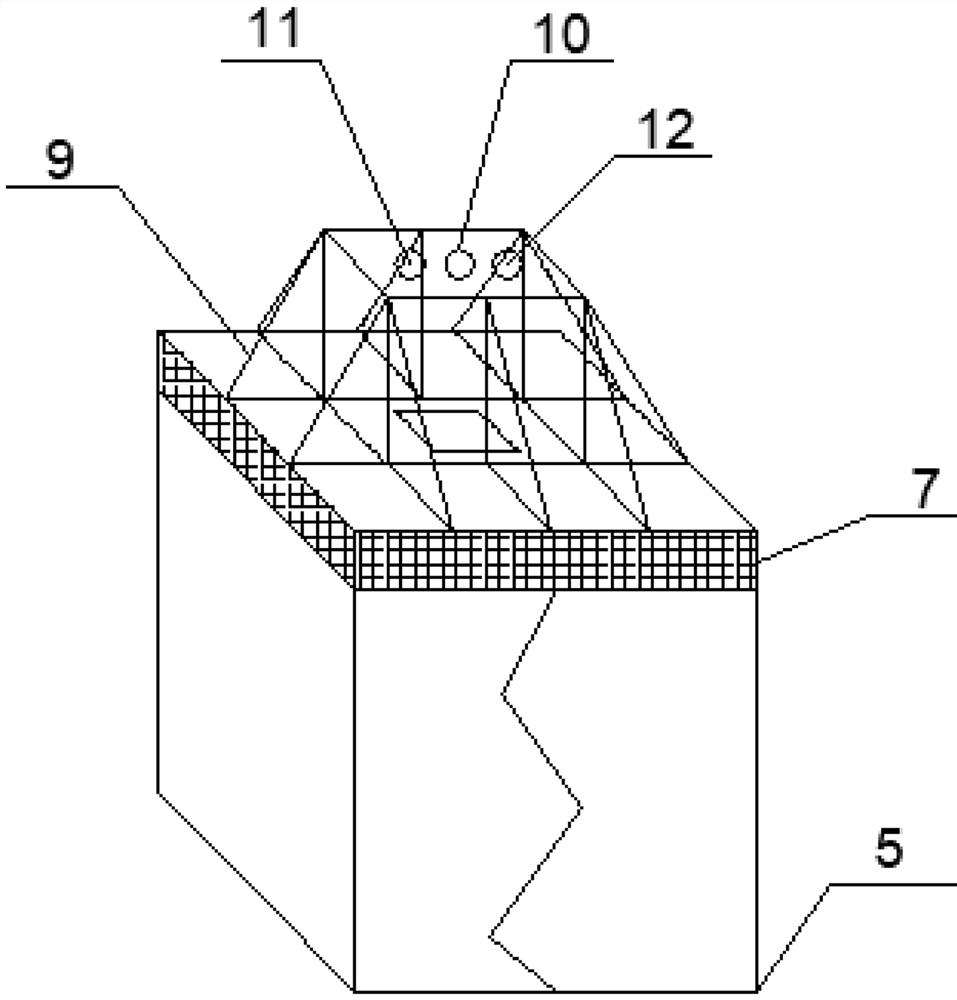

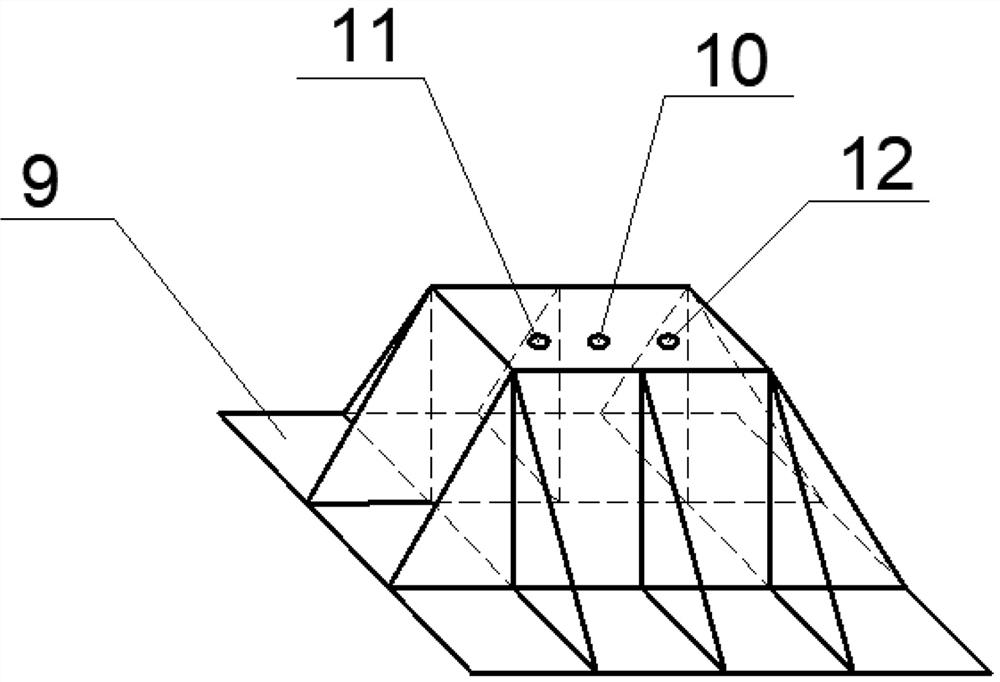

[0044] see Figure 1-4 , an experimental device for repairing membrane bag concrete cracks by vacuum grouting, which includes a main body load-bearing frame 1, a sample fixing frame 3 is installed on the top support of the main body load-bearing frame 1, and a reaction force frame 6 is installed on the sample fixing frame 3 Membrane bag concrete sample 5, silica gel cushion 7 and vacuum cover 9; the vacuum cover 9 is provided with a grouting hole 10, a suction hole 11 and a measuring hole 12; the grouting hole 10 is connected with the grouting equipment 14, and the suction hole 11 is connected with vacuum suction equipment 15; Vacuum pressure gauge 13 is installed on the measuring hole 12. By adopting the above-mentioned experimental device, it can be used to simulate and solve the problem that the grout cannot enter the crack due to the insufficient removal of water vapor inside the crack in the membrane bag concrete crack repair project, and the micro cracks cannot be filled...

Embodiment 2

[0055] Adopt described experimental device to carry out the experimental method of vacuum grouting repair film bag concrete crack, comprise the following steps:

[0056] Step1. Material preparation: Prepare the main load-bearing frame 1, telescopic rod 2, sample fixing frame 3, concrete, membrane bag concrete sample 5, reaction force frame 6, silicone cushion 7, magnet 8, vacuum cover 9, vacuum cover 9. Grouting hole 10, suction hole 11, measuring hole 12, vacuum pressure gauge 13, grouting equipment 14, vacuum suction equipment 15, mortar 16, acrylic board and grid wire;

[0057] Step2. Make the main load-bearing frame 1: The main load-bearing frame 1 is made of stainless steel in the processing plant, and the main load-bearing frame 1 includes the telescopic rod 2 and the sample fixing frame 3;

[0058] Step3. Make membrane bag concrete sample 5: Arrange the membrane bag inside the membrane bag concrete sample mold and fix it, then pour the configured concrete into the mold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com