Porous ceramic heating element with embedded atomizer and preparation process of porous ceramic heating element

A technology of porous ceramics and heating elements, applied in the direction of tobacco, etc., can solve the problems of slow heating speed, slow atomization speed, uneven heating of the heating body, etc., and achieve good user experience, fast atomization speed, and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

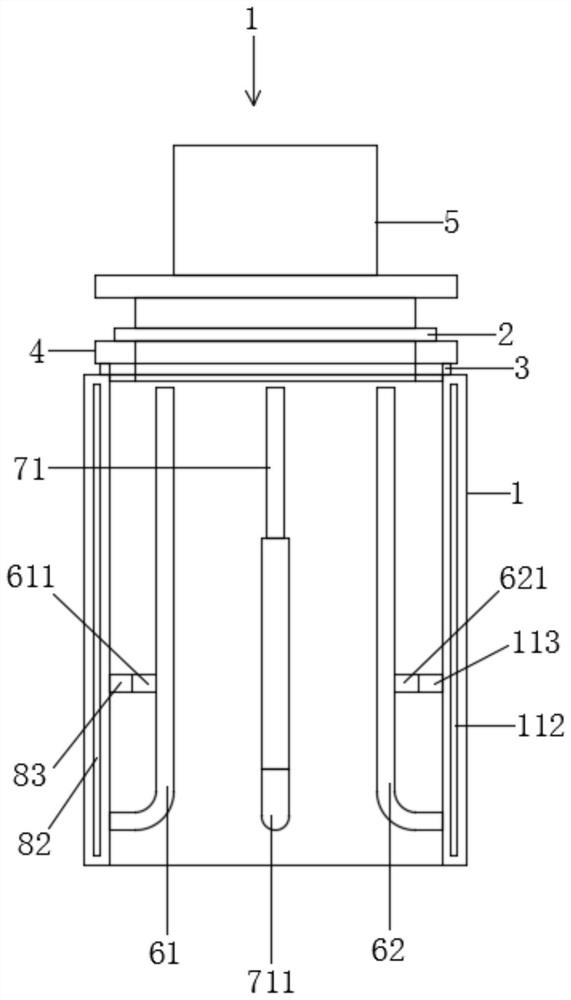

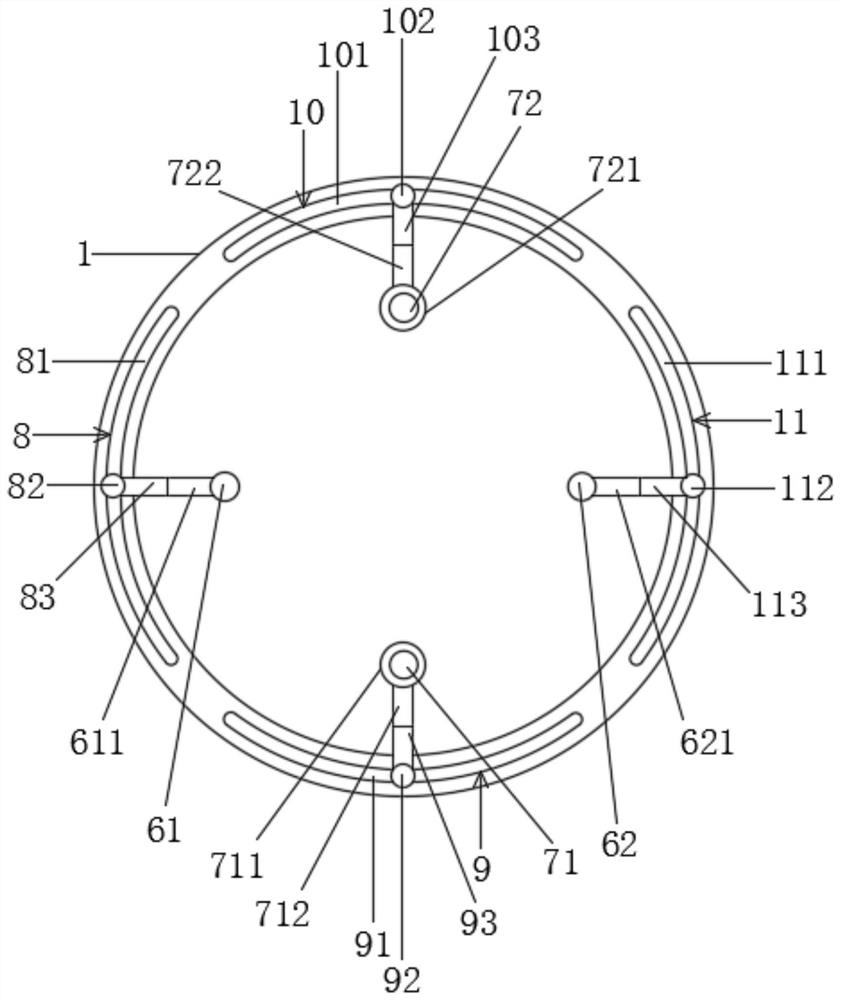

[0038] The present invention provides a porous ceramic heating element with a built-in atomizer, please refer to Figure 1-4 , including a cylinder body 1 and an electrode 5, the electrode 5 is provided with two positive pole interfaces and two negative pole interfaces, the cylinder body 1 and the electrode 5 are detachably connected, and the inner cavity of the cylinder body 1 is provided with two conductive leads The foot group is respectively the first conductive pin group composed of the first conductive pin 61 and the second conductive pin 62, and the second conductive pin group. The second conductive pin group consists of the first rod body 71, the first The internally threaded pipe body 711, the second rod body 72 and the second internally threaded pipe body 721 are formed, the inner wall of the first internally threaded pipe body 711 is threadedly connected to the first rod body 71, and the inner wall of the second internally threaded pipe body 721 is threadedly connect...

Embodiment 2

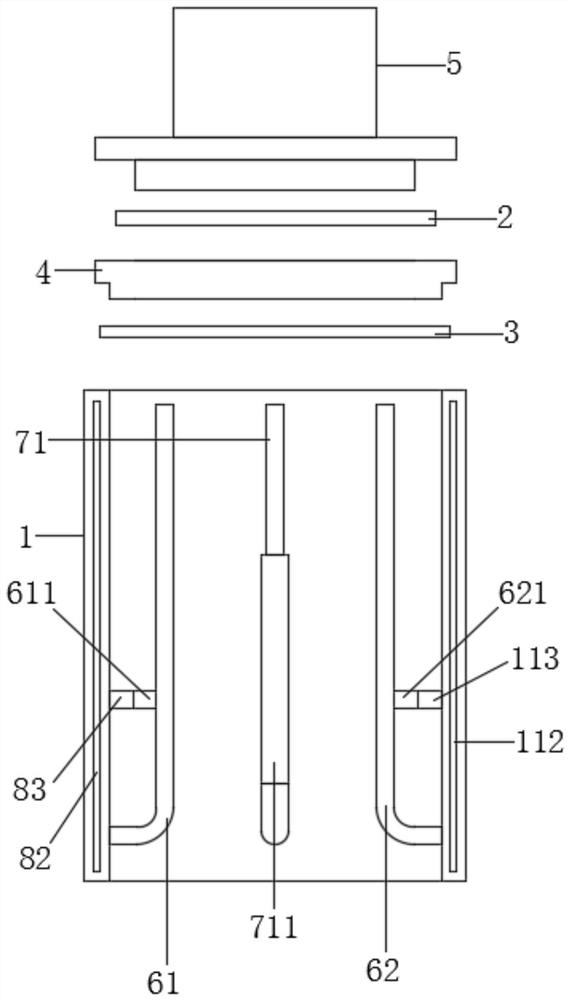

[0044] see Figure 5-9 The difference from Example 1 is that the electrode 5, the insulating ring 4 and the cylinder body 1 are fixed by a fixer 12, and the fixer 12 includes a fixed disc 131, one end of which is fixed to a connecting pin 135, and the other end of the outer wall is threaded and embedded The bar 134, the plug 135 is provided with a movable disc 133 and a spring 132, the electrode 5 is provided with a first through hole 51, the first insulating washer 2 is provided with a second through hole 21, and the insulating ring 4 is provided with a third through hole. hole 41, the second insulating gasket 3 is provided with a fourth through hole 31, the inner wall of the cylinder body 1 is provided with a fixed block 12, and the fixed block 12 is provided with a through hole 121, a rectangular through hole 123 and a snap-in groove 122, and the embedded strip 134 is stuck in the slot 122.

[0045] In specific use, if the user does not use the second conductive pin group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com