Rectifying tower top reflux temperature adjusting system and process

A technology of reflux temperature and regulation system, which is applied in the direction of distillation regulation/control, piping system, distillation separation, etc. It can solve problems such as unstable operation of equipment, cavitation, and low pressure of reflux tank, so as to ensure safe and stable operation and ensure equipment Stable operation and heat balance maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

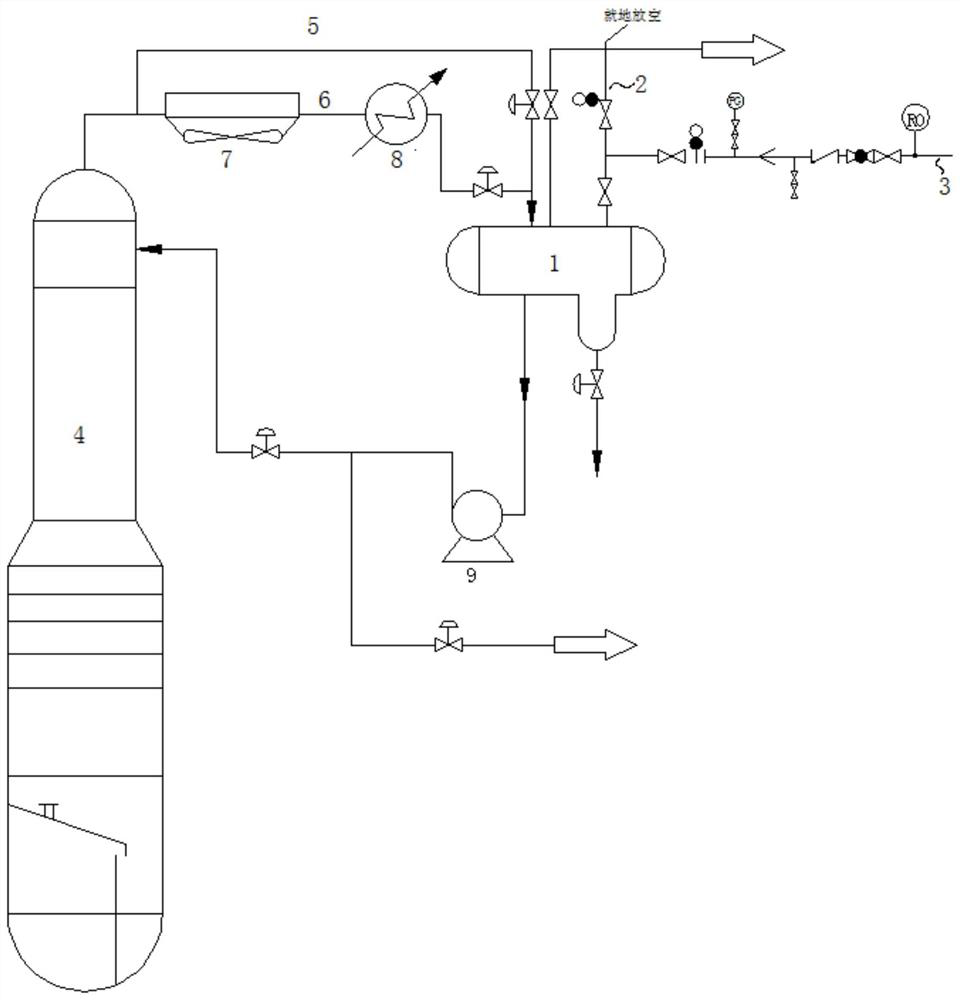

[0039] Such as figure 1 As shown, this embodiment provides a rectification tower top reflux temperature adjustment system, including a temperature control tube group, a reflux tank 1, a vent line 2 and a booster line 3,

[0040] One end of the temperature control tube group is communicated with the top of the rectification tower 4, and the other end is communicated with the inlet of the reflux tank 1, and the reflux port of the reflux tank 1 is communicated with the top of the rectification tower 4. The venting line 2 communicates with the top of the reflux tank 1, and the booster line 3 communicates with the middle of the vent line 2;

[0041] The temperature control tube group includes a hot bypass 5 and a cooling bypass 6 arranged in parallel, the hot bypass 5 is provided with a hot bypass valve, and the cooling bypass 6 is provided with a cold bypass valve.

[0042] Wherein, the bottom side of the return tank 1 is connected with a water diversion part, water and oil are s...

Embodiment 2

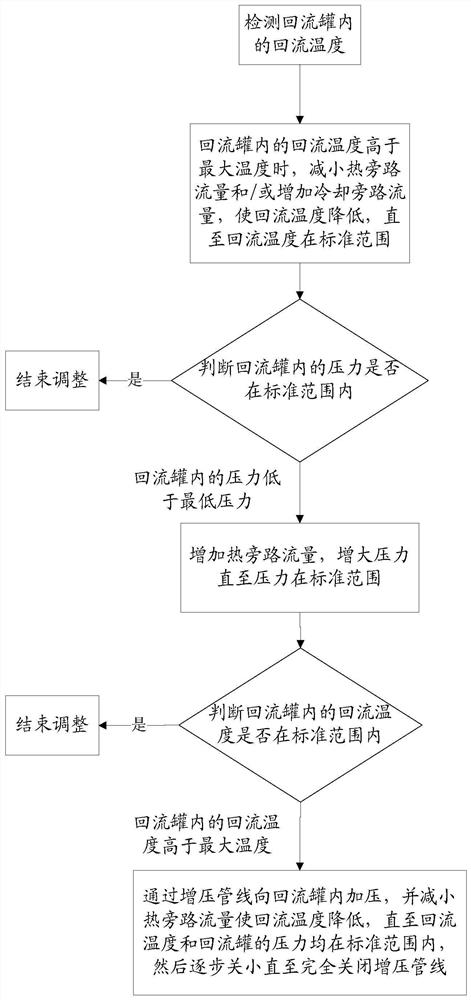

[0054] This embodiment provides a rectification tower top reflux temperature adjustment process, which is realized by the rectification tower top reflux temperature adjustment system described in Embodiment 1, including the following steps:

[0055] Step 1: Detect the reflux temperature in the reflux tank 1;

[0056] Step 2: When the reflux temperature in the reflux tank 1 is higher than the maximum temperature, reduce the flow rate of the hot bypass 5 and / or increase the flow rate of the cooling bypass 6 to reduce the reflux temperature until the reflux temperature is within the standard range;

[0057] Step 3: Determine whether the pressure in the return tank 1 is within the standard range:

[0058] If the pressure in the return tank 1 is within the standard range, then end the adjustment;

[0059] If the pressure in the reflux tank 1 is lower than the minimum pressure, increase the flow rate of the thermal bypass 5 and increase the pressure until the pressure is within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com