Method for controlling general size uniformity of rod and wire finished products

A technology of uniform size and control method, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem that the uniformity of the through-length size is greatly affected by the experience of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for controlling the general dimensional uniformity of finished rods and wires provided by an embodiment of the present invention includes the following steps:

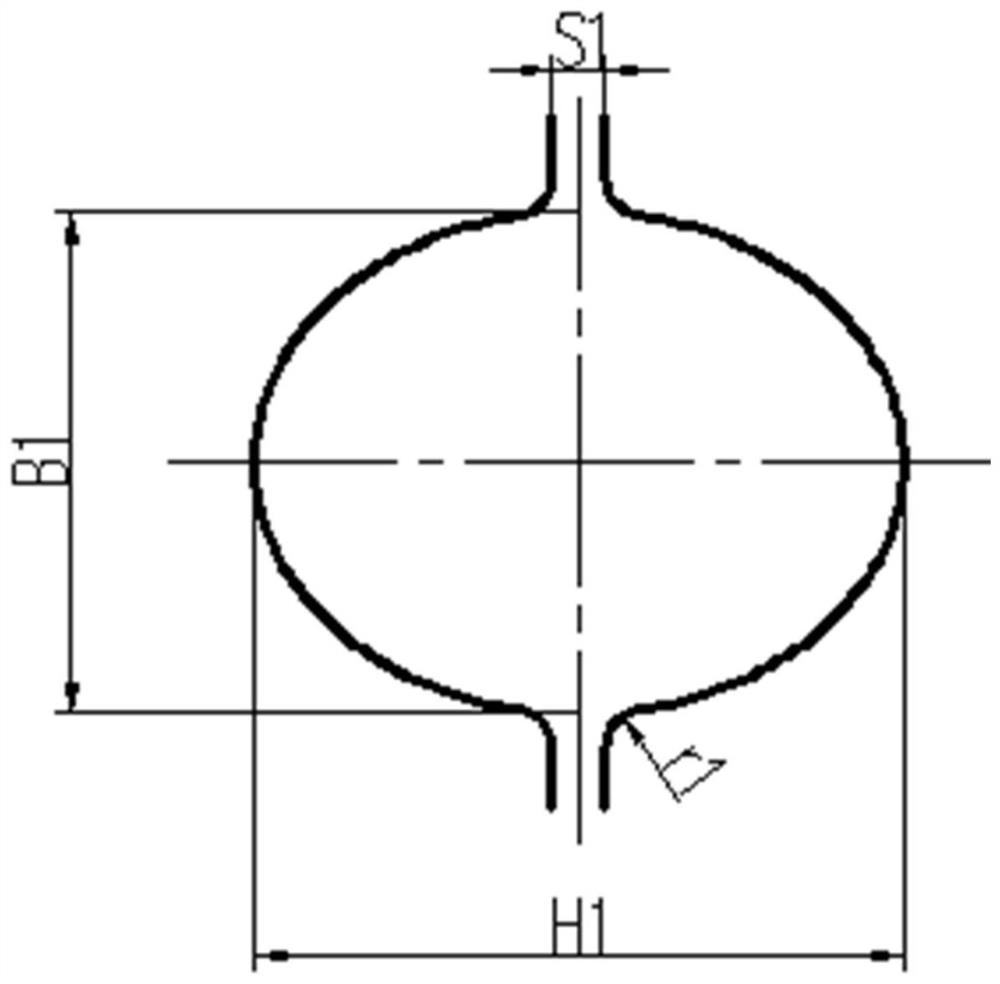

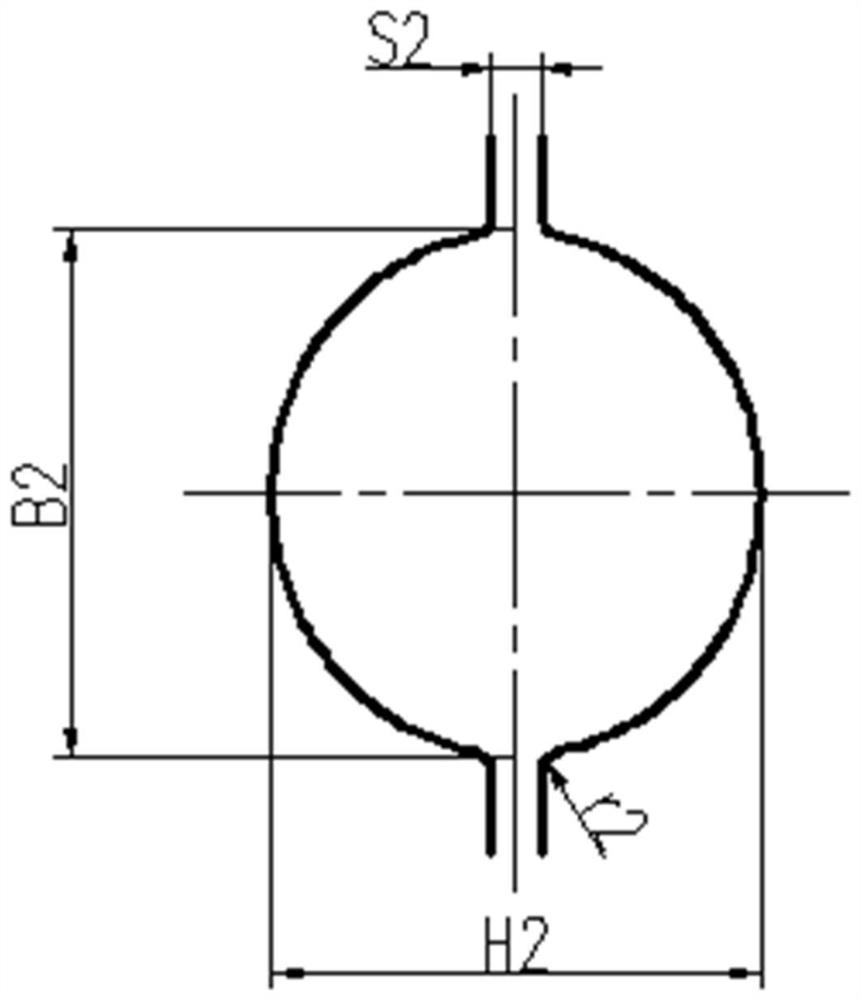

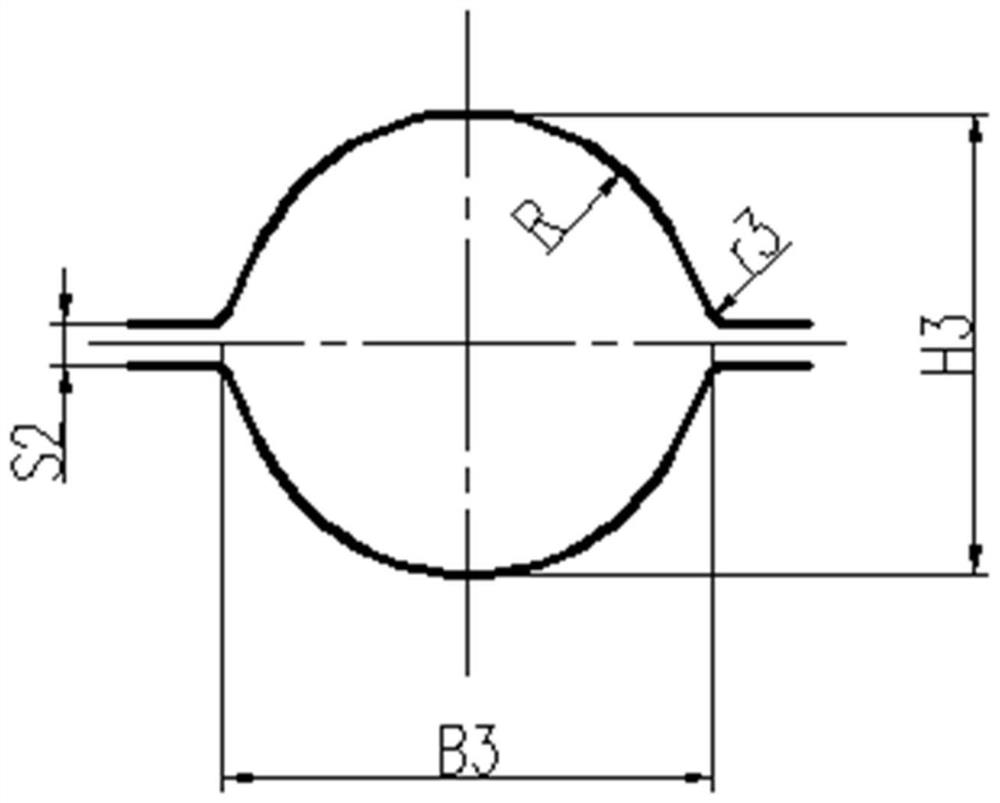

[0024] Step S1, when the production line is a bar mill production line, the last two rolling stands of the roughing group of the bar rolling production line adopt the ellipse-transformed elliptical pass system, and the last two rolling stands of the middle rolling group of the bar mill production line adopt the metamorphic circular pass system. - Round hole type system.

[0025] Step S2, when the production line is a high-speed wire-rod mill production line or a high-bar mill production line, the last two stands of the rough-rolling unit of the high-speed wire-rod mill production line or the high-bar mill production line adopt the elliptical-abnormal elliptical pass system, and the high-speed wire mill production line or the high-bar mill production line The last two rolling mills of the middle rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com