Cylindrical battery steel shell stretching forming device

A technology of stretch forming and cylindrical batteries, which is applied in the direction of forming tools, feeding devices, positioning devices, etc., and can solve the problems of reduced work stretching efficiency, defective products, and high cost of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

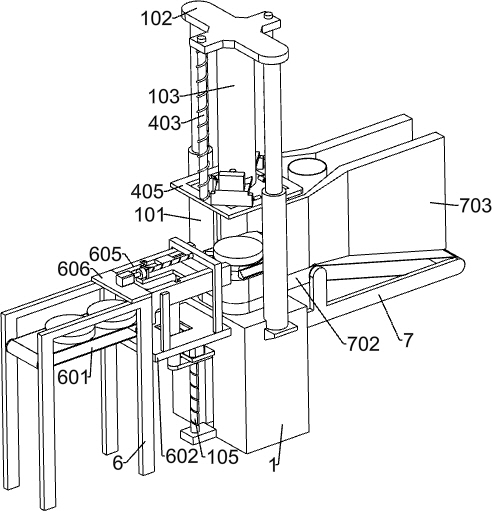

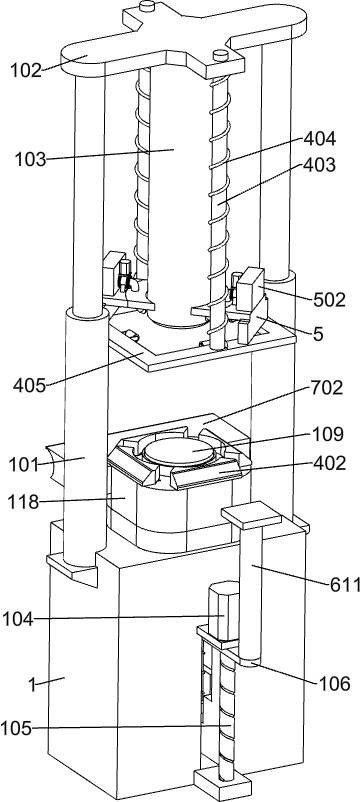

[0040] A cylindrical battery steel shell drawing device, such as Figure 1-14 As shown, it includes a stretching seat 1, a hydraulic cylinder 101, a cross plate 102, a die rod 103, a first motor 104, a first screw rod 105, a first connecting plate 106, a second connecting plate 107, a support column 108, The support plate 109, the first guide rod 110, the first base plate 111, the first mold 112, the first spring 113, the second guide rod 114, the second base plate 115, the second spring 116, the second mold 117, the support seat 118 and Grading mechanism, the stretching seat 1 is a hollow seat, two hydraulic cylinders 101 are symmetrically installed on the stretching seat 1, the telescopic shafts of the hydraulic cylinders 101 can be extended upward, and the telescopic shafts of the two hydraulic cylinders 101 are jointly connected with Cross plate 102, the cross plate 102 is installed with a die rod 103, the die rod 103 is a straight rod that can stretch and form a steel pla...

Embodiment 2

[0043] On the basis of Example 1, as Image 6 and Figure 7 As shown, the grading mechanism includes a first guide plate 2, a second guide plate 201, a third guide rod 202, a lower support plate 203, a third spring 204, a fourth guide rod 206, an upper support plate 207, a fourth spring 208 and a trigger On the rod 210, two first guide plates 2 are fixed symmetrically on the second connecting plate 107. The first guide plates 2 play the role of supporting and guiding, and the two first guide plates 2 are symmetrically fixed with second guide plates 201. Two third guide rods 202 are symmetrically slidably connected to the two second guide plates 201 , the third guide rods 202 are cylindrical straight rods, and the two third guide rods 202 are symmetrically fixed with lower support plates 203 . The end of the lower support plate 203 away from the third guide rod 202 is an inclined plane, and the lower support plate 203 is slidably connected with the first guide plate 2 on the s...

Embodiment 3

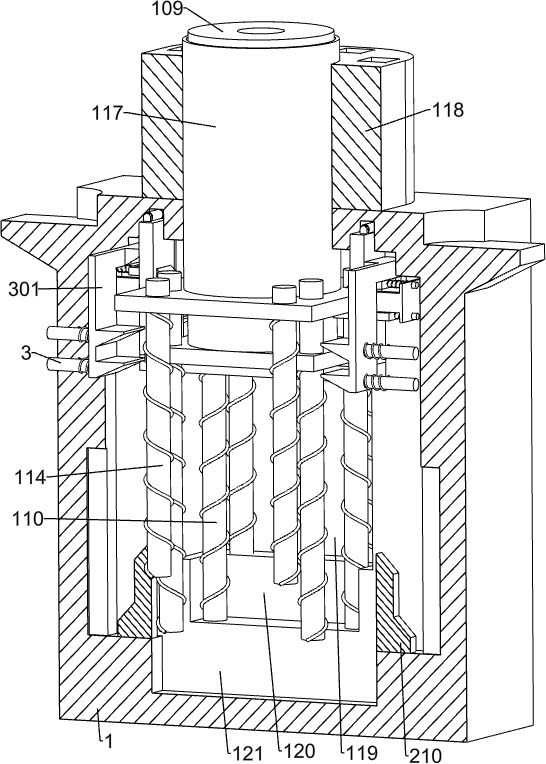

[0046] On the basis of Example 2, such as image 3 and Figure 8 As shown, it also includes a limit mechanism, the limit mechanism includes the fifth guide rod 3, the first support plate 301, the blocking plate 302, the fifth spring 303 and the expansion block 304, and the symmetrical sliding connection in the stretching seat 1 has There are eight fifth guide rods 3, and the fifth guide rods 3 play a guiding role. A first support plate 301 is fixedly connected to two adjacent fifth guide rods 3. There are four first support plates 301 in total. A plate 301 is provided with two blocking plates 302, the upper end of the blocking plate 302 is a plane, the lower end of the blocking plate 302 is an inclined surface, the fifth guide rod 3 is equipped with a fifth spring 303, the fifth spring 303 is The first support plates 301 on both sides provide a force close to each other. A strut block 304 is fixedly connected to the two first support plates 301 on the same side. The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com