Bilateral pouring process for wind power blade web

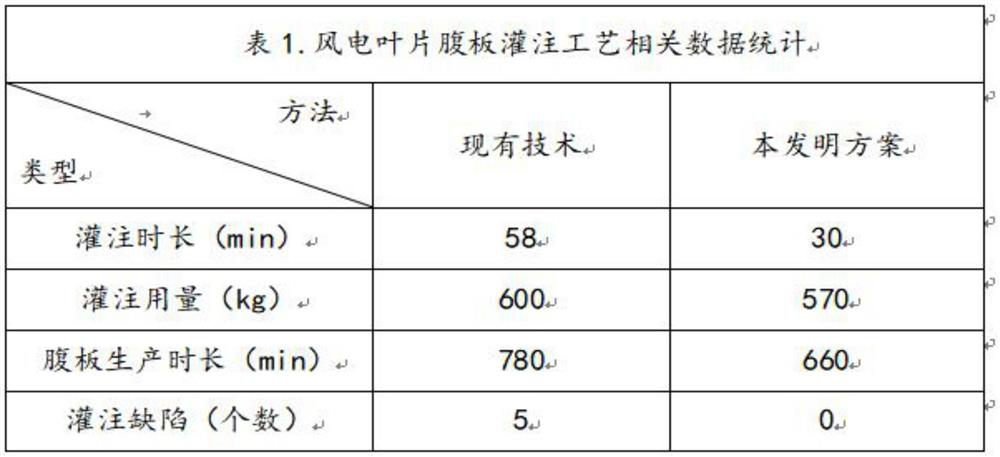

A technology for wind turbine blades and webs, which is applied in the field of bilateral perfusion technology of wind turbine blade webs, can solve the problems of aggravating perfusion defects, perfusion defects, and high amount of perfusion resin, so as to solve the problem of insufficient supply of components, shorten perfusion time, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example: Preferably, take the production of 70-meter-level blades as an example

[0024] (1) Basic layering: In the blade web mold, lay the outer skin release cloth, blade web outer skin glass fiber jacket, core material, blade web inner skin glass fiber jacket, trailing edge web Plate lightning conductor, inner skin release cloth, wherein the outer skin release cloth and inner skin release cloth are only laid on the web bonding area, and the outer skin release cloth and inner skin release cloth are torn off by web forming, and This is to create a rough surface in the web bonding area, and continue to lay the porous film after the outer skin release cloth is laid. The porous film covers all the material surfaces in the cavity of the blade web mold to facilitate the subsequent removal of web auxiliary materials. ;

[0025] (2) Laying of diversion net: Lay a large-surface diversion net on the porous membrane. The large-surface diversion net is arranged at the center of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com