Self-pressurizing device for liquid helium dewar and pressurizing method

A pressurization device, helium dewar technology, applied in the field of self-pressurization device of liquid helium dewar, can solve the problems of waste of helium, high cost, etc., to reduce the cost of use and safety, reduce the cost of recycling, fast heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

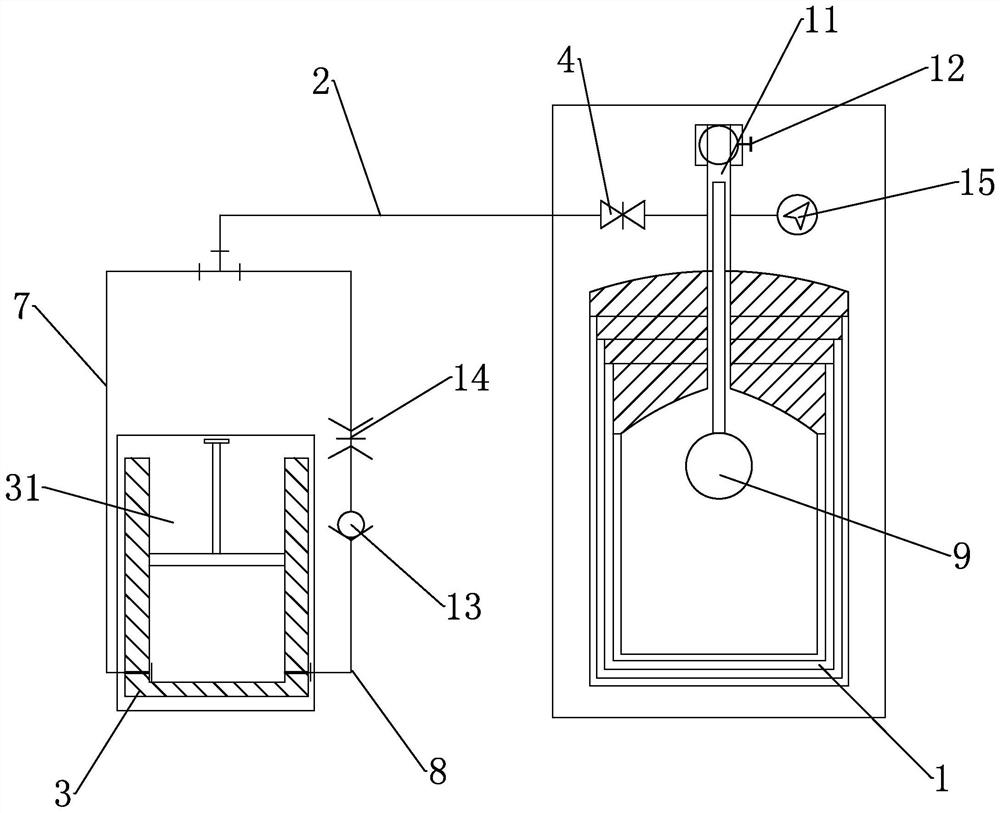

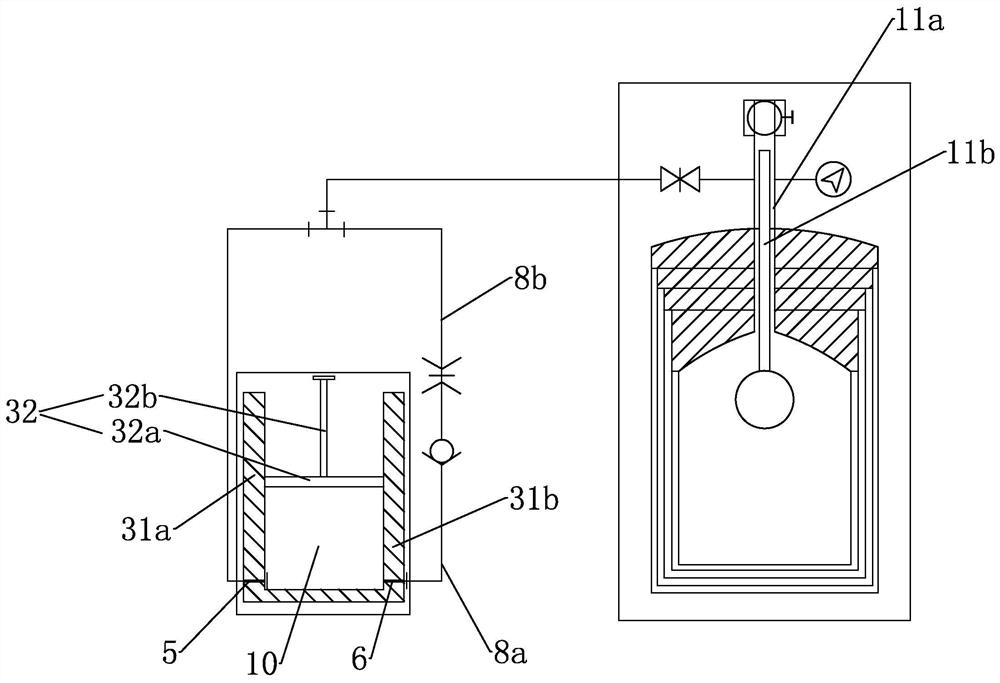

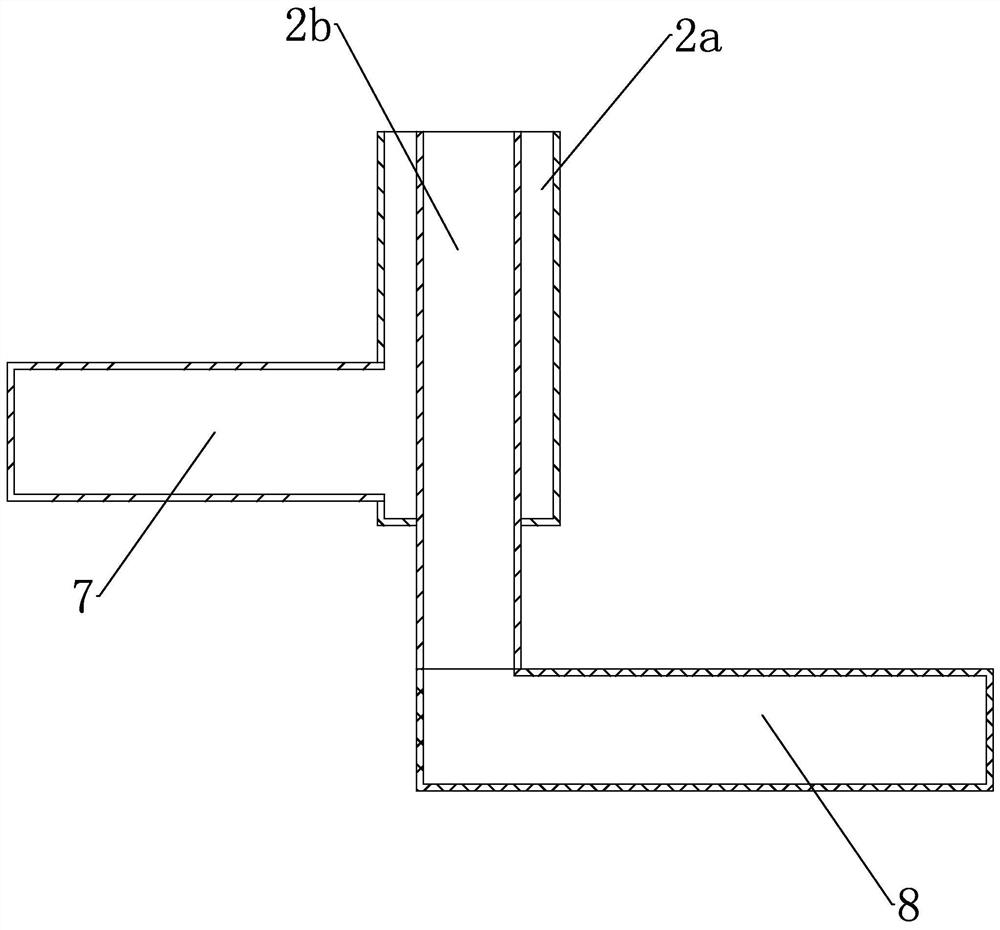

[0035] Such as Figure 1 to Figure 3 As shown, a self-pressurizing device for liquid helium Dewar includes a Dewar 1 for storing low-temperature liquefied gas. The Dewar communicates with an external heat exchange piston 3 through a first pipeline 2. On the first pipeline, A booster valve 4 is provided, the heat exchange piston includes a heat exchange chamber 31 and a piston rod 32 that can reciprocate and slide in the heat exchange chamber, the first pipeline includes an outer tube 2a and an inner tube 2b, the middle of the outer tube and the inner tube The gas flows are independent of each other. The heat exchange chamber includes a first side wall 31a and a second side wall 31b. The first side wall is provided with an intake valve 5, and the second side wall is provided with an exhaust valve 6. The intake valve The end of the outer tube away from Dewar is connected through the second pipeline 7, the exhaust valve is connected with the end of the inner tube away from Dewar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com