Patents

Literature

31results about How to "Shorten infusion time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

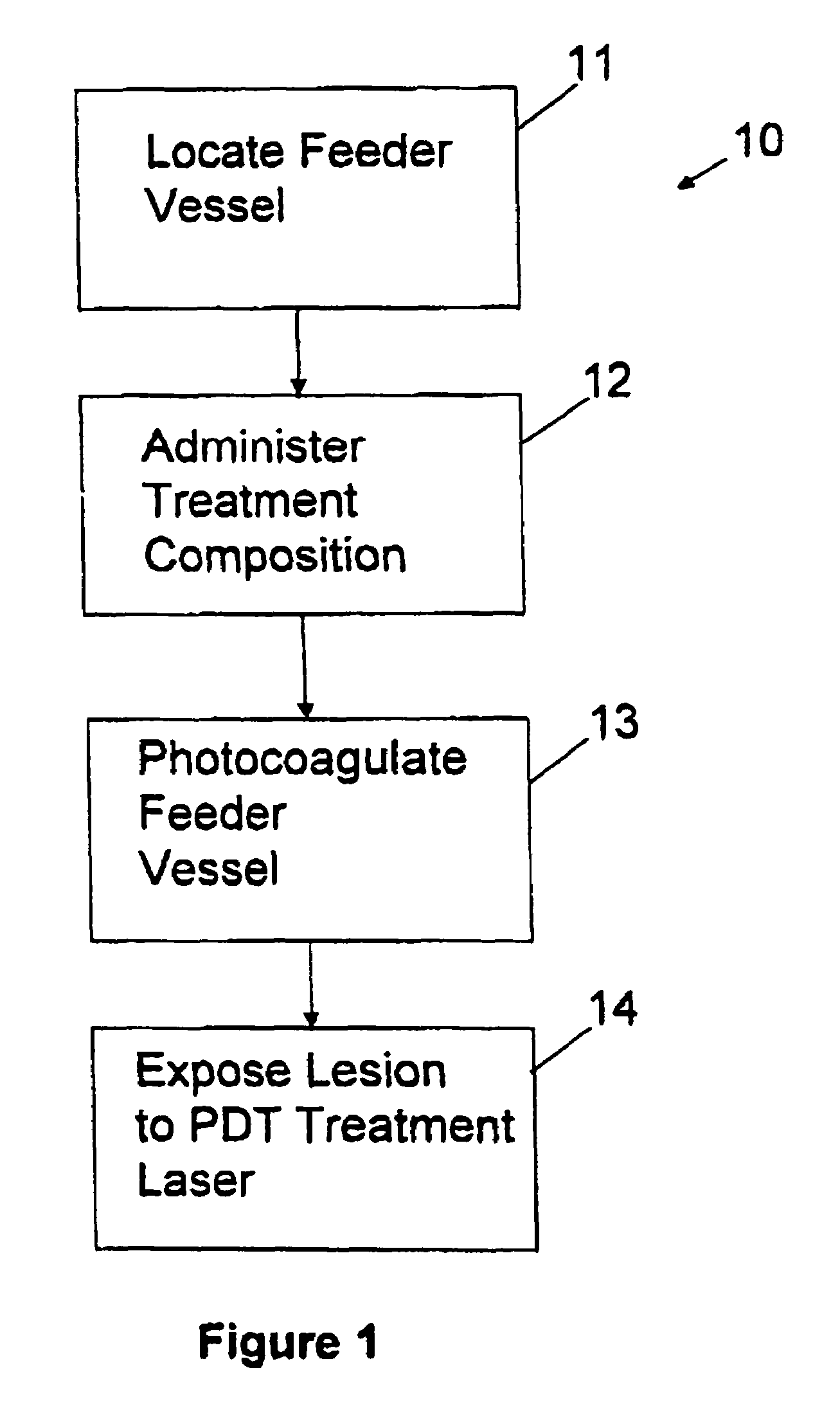

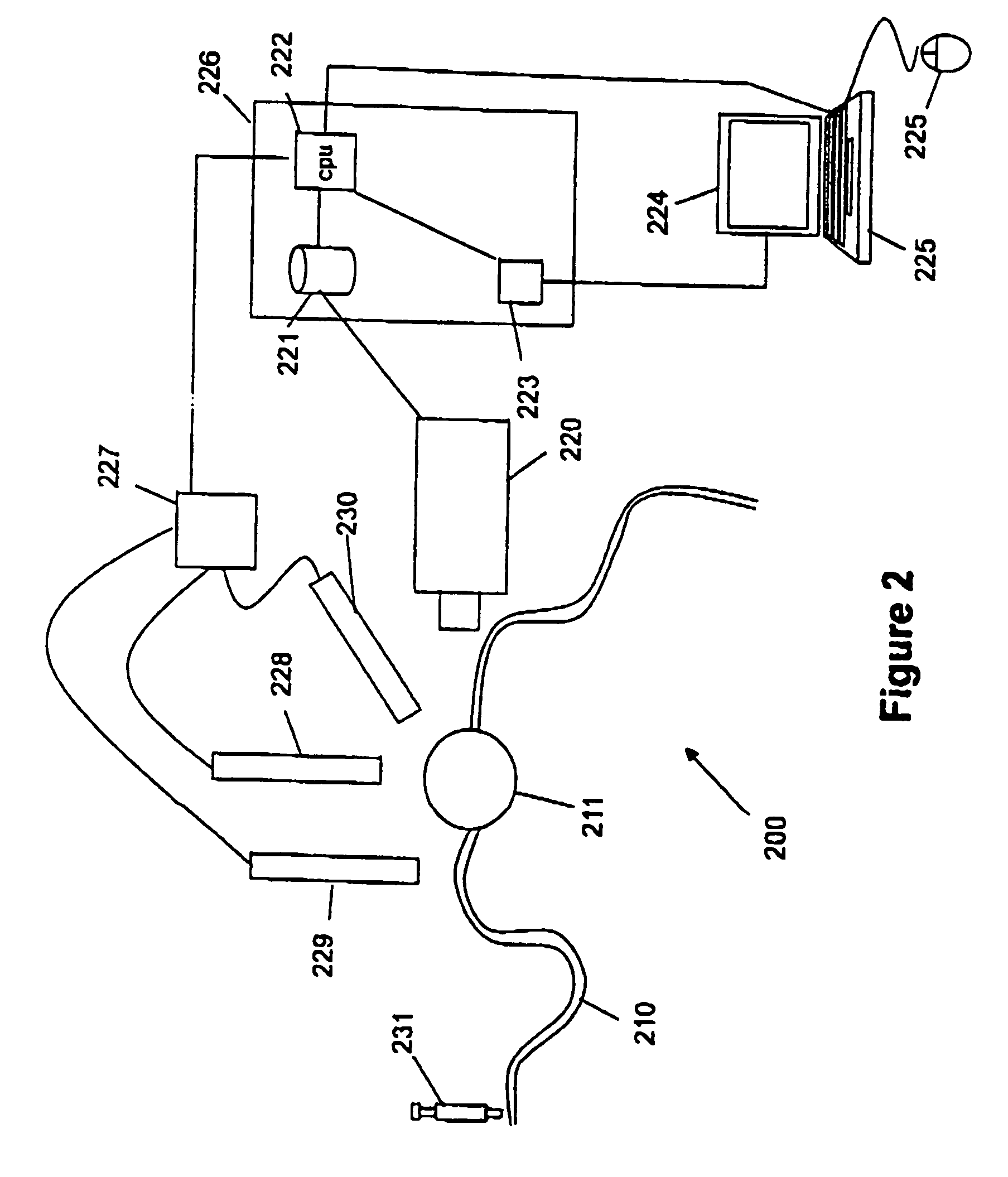

Combined photocoagulation and photodynamic therapy

InactiveUS7364574B2High flush-out rateAvoid damageLaser surgeryDiagnosticsPhotodynamic therapyLesion site

A method for treating a lesion of an animal, the animal having at least one vessel that carries blood to the lesion, comprising locating the vessel, administering a composition comprising a photodynamic agent, applying energy to the vessel to photocoagulate the vessel and thereby reduce the rate at which the treatment composition exits said lesion and applying energy to said lesion, of a type and an amount sufficient to excite the photodynamic agent, causing the lesion to undergo photodynamic therapy. Preferably, a dye that is both a fluorescent dye and a radiation absorbing dye, such as indocyanine green dye, is added to the treatment composition to allow (a) confirmation of the presence of the treatment composition in the lesion to be detected by fluorescent angiography and (b) the rate of blow flow to be reduced in the blood vessel feeding the lesion using dye enhanced photocoagulation.

Owner:NOVADAG TECH INC

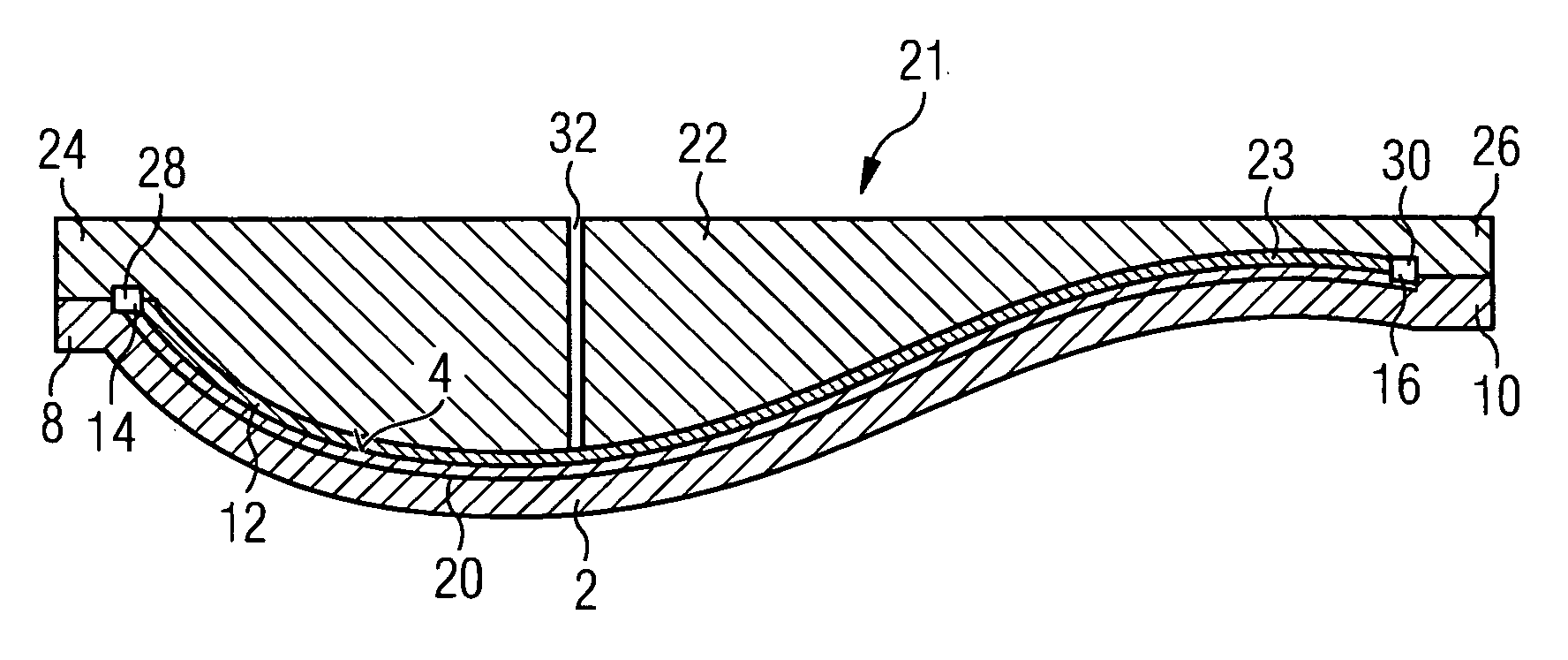

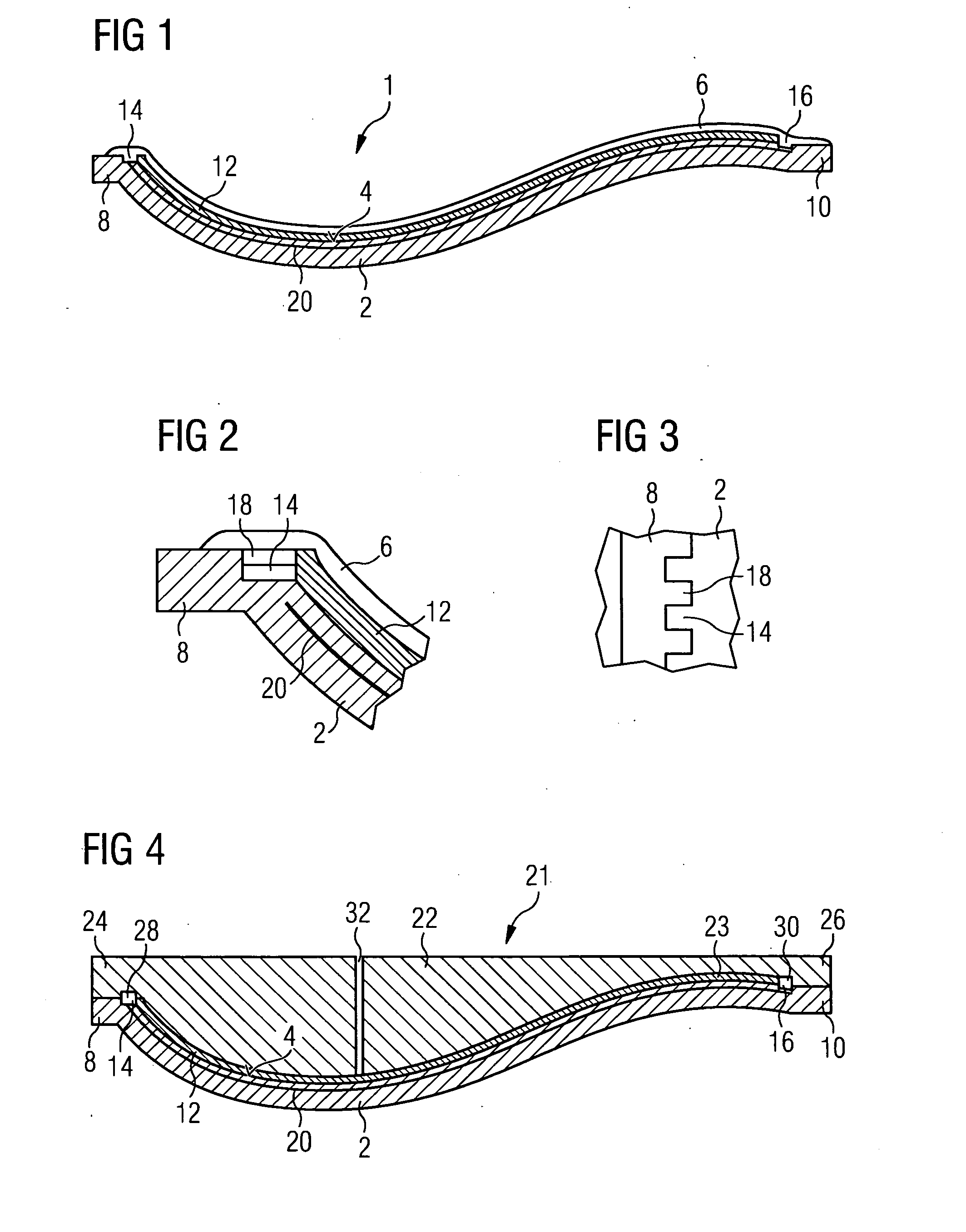

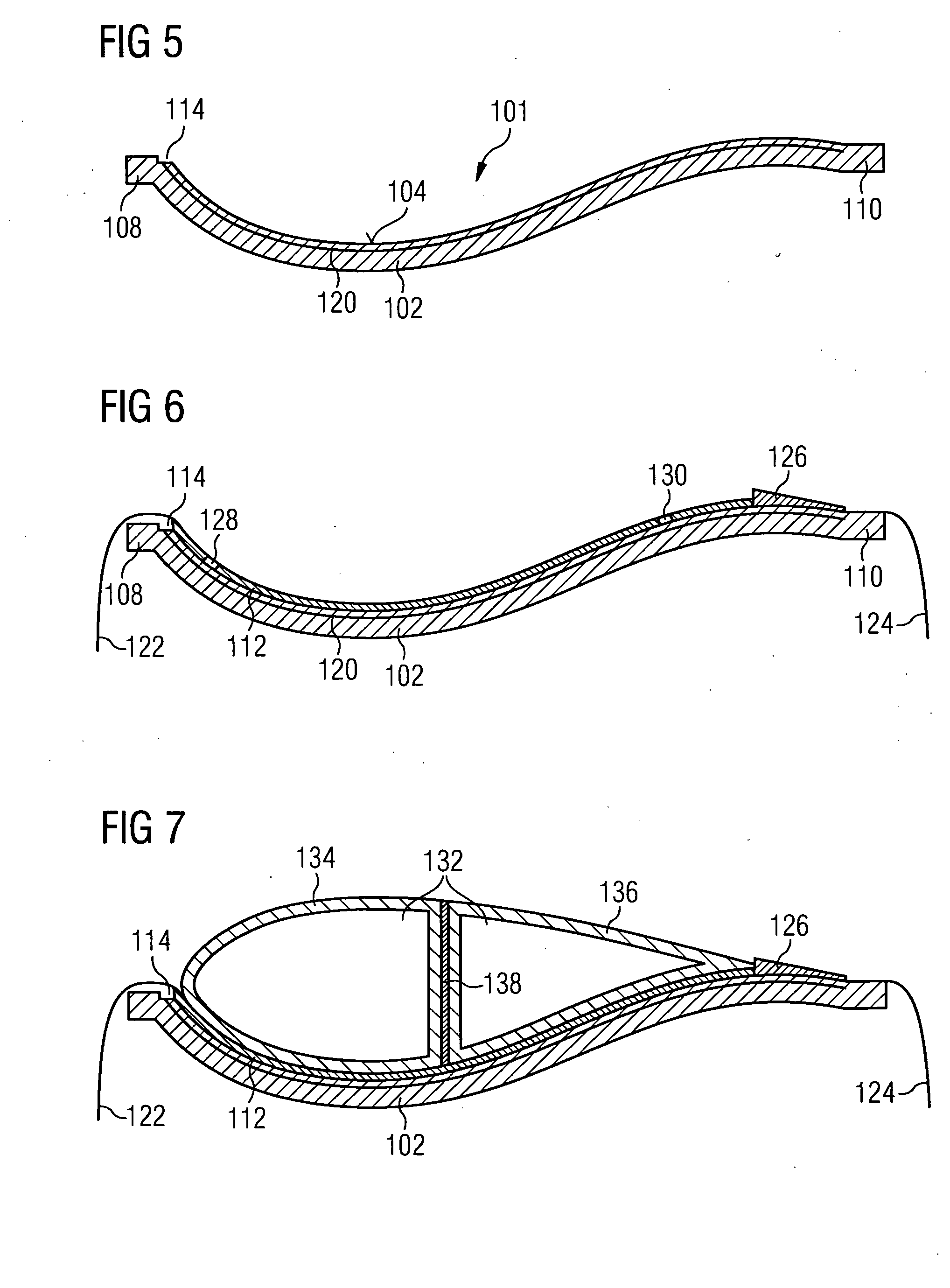

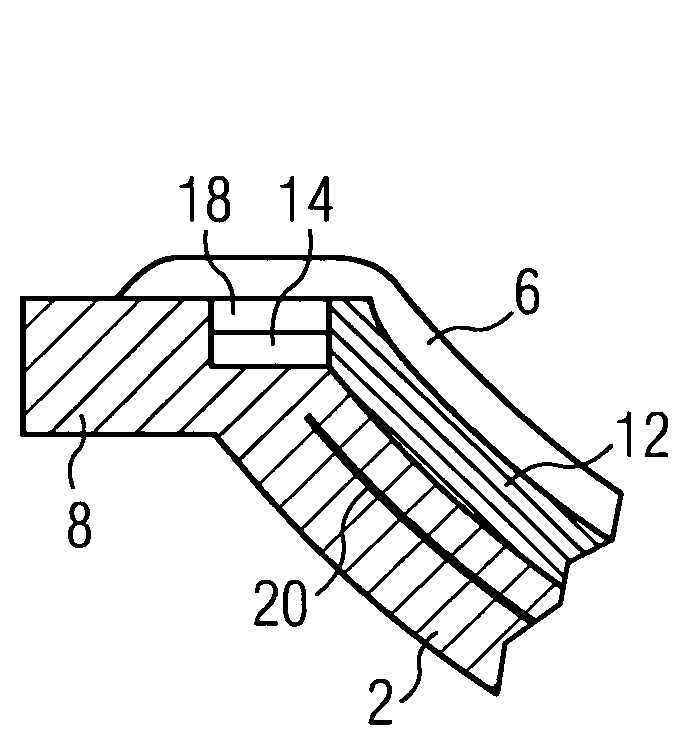

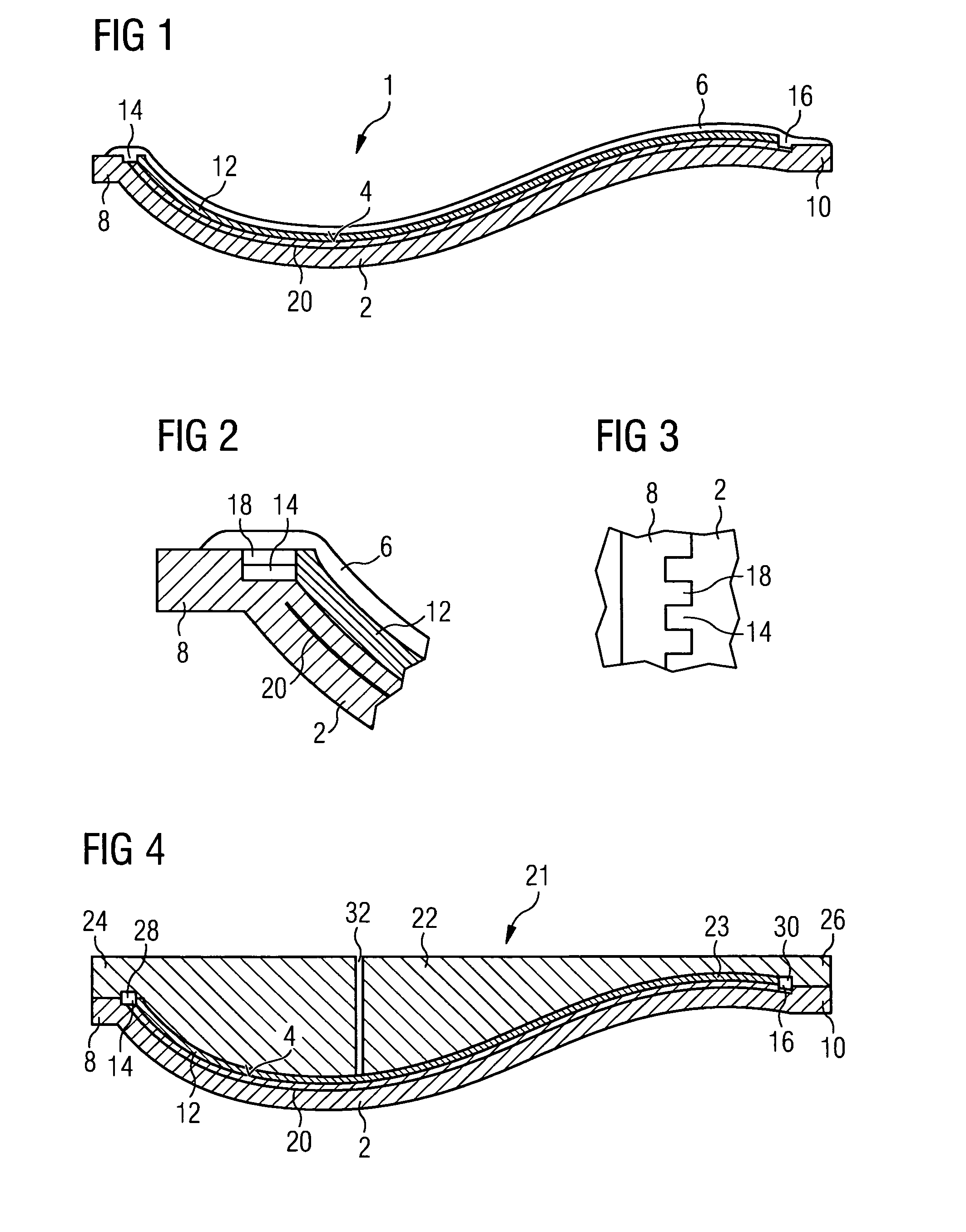

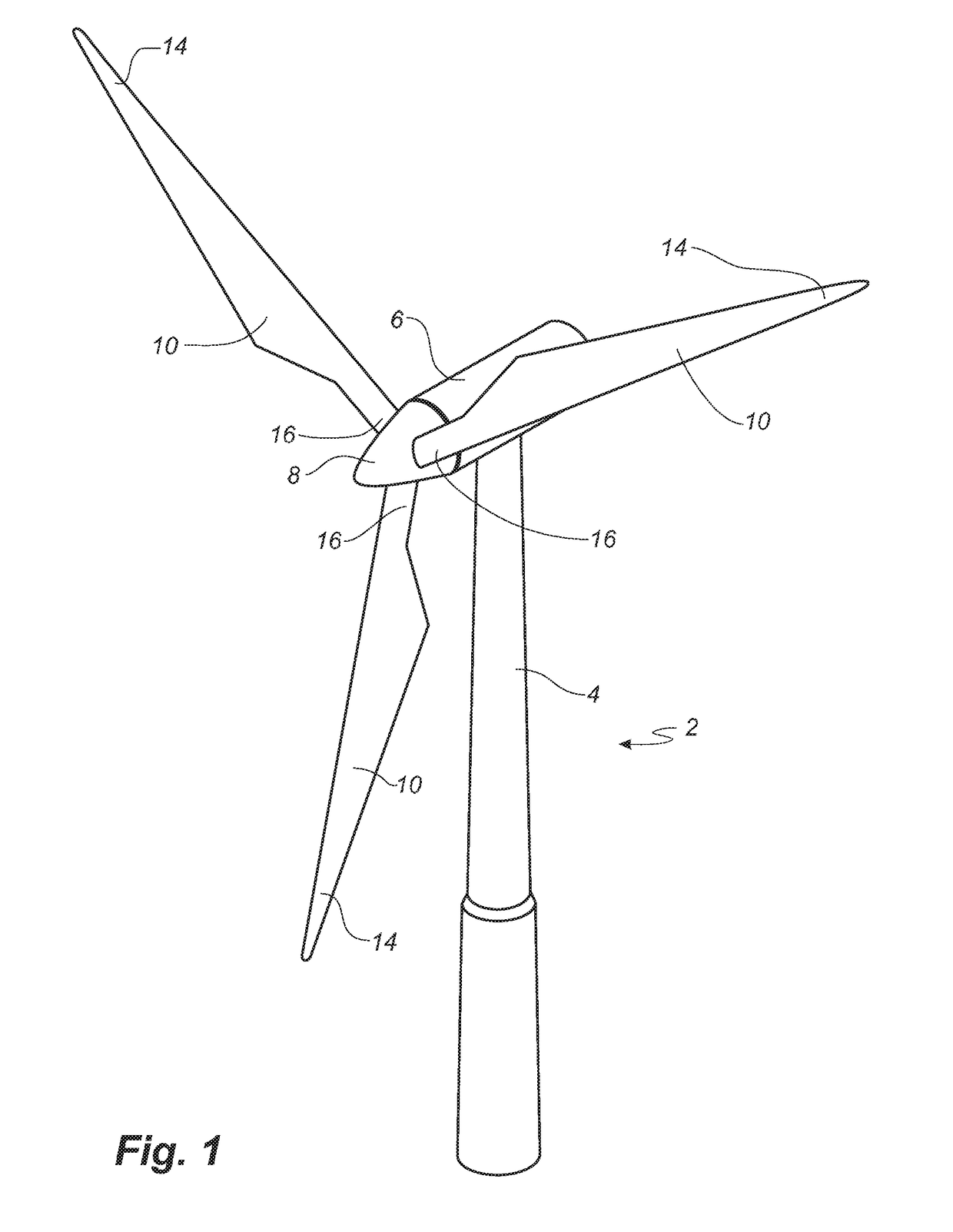

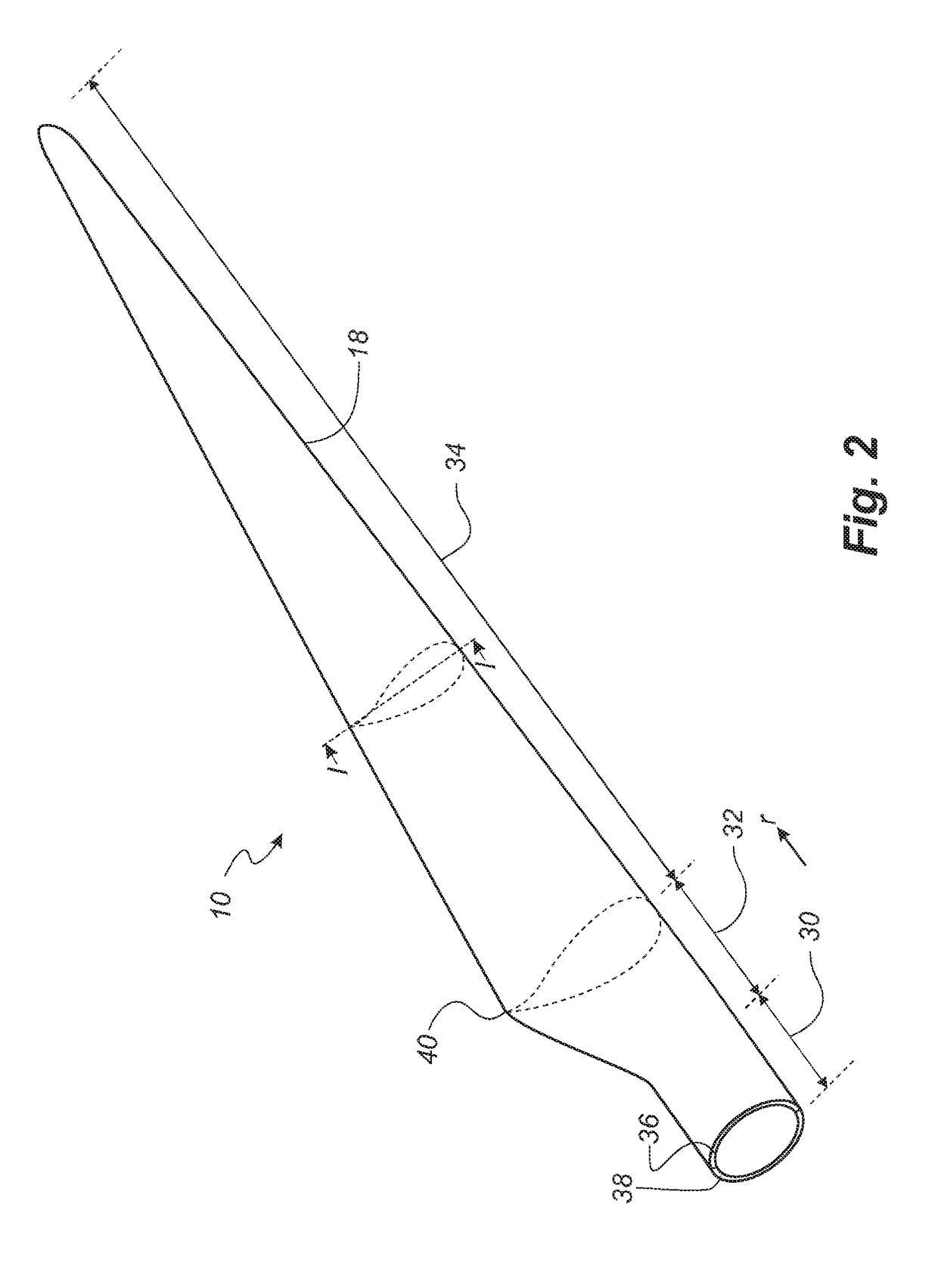

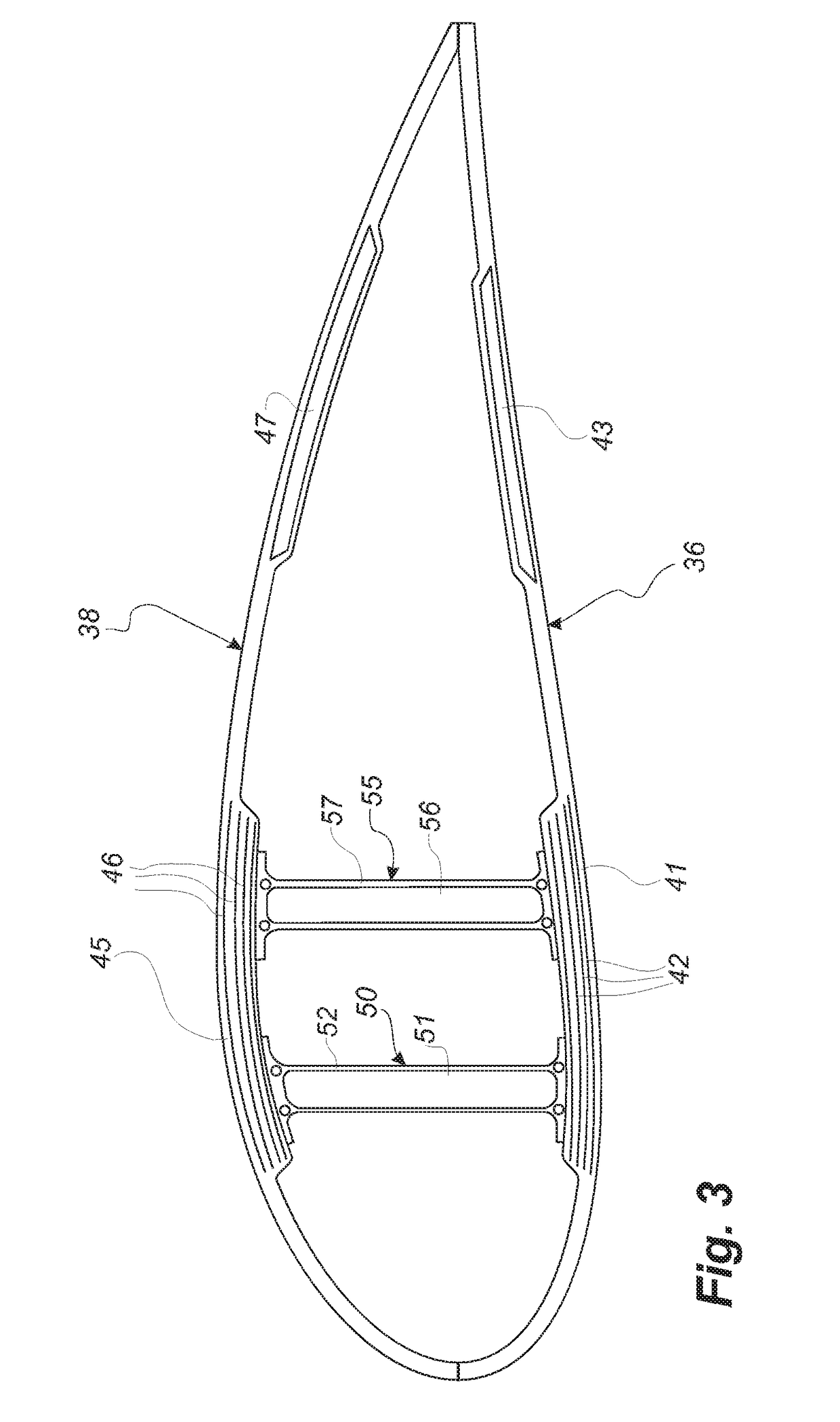

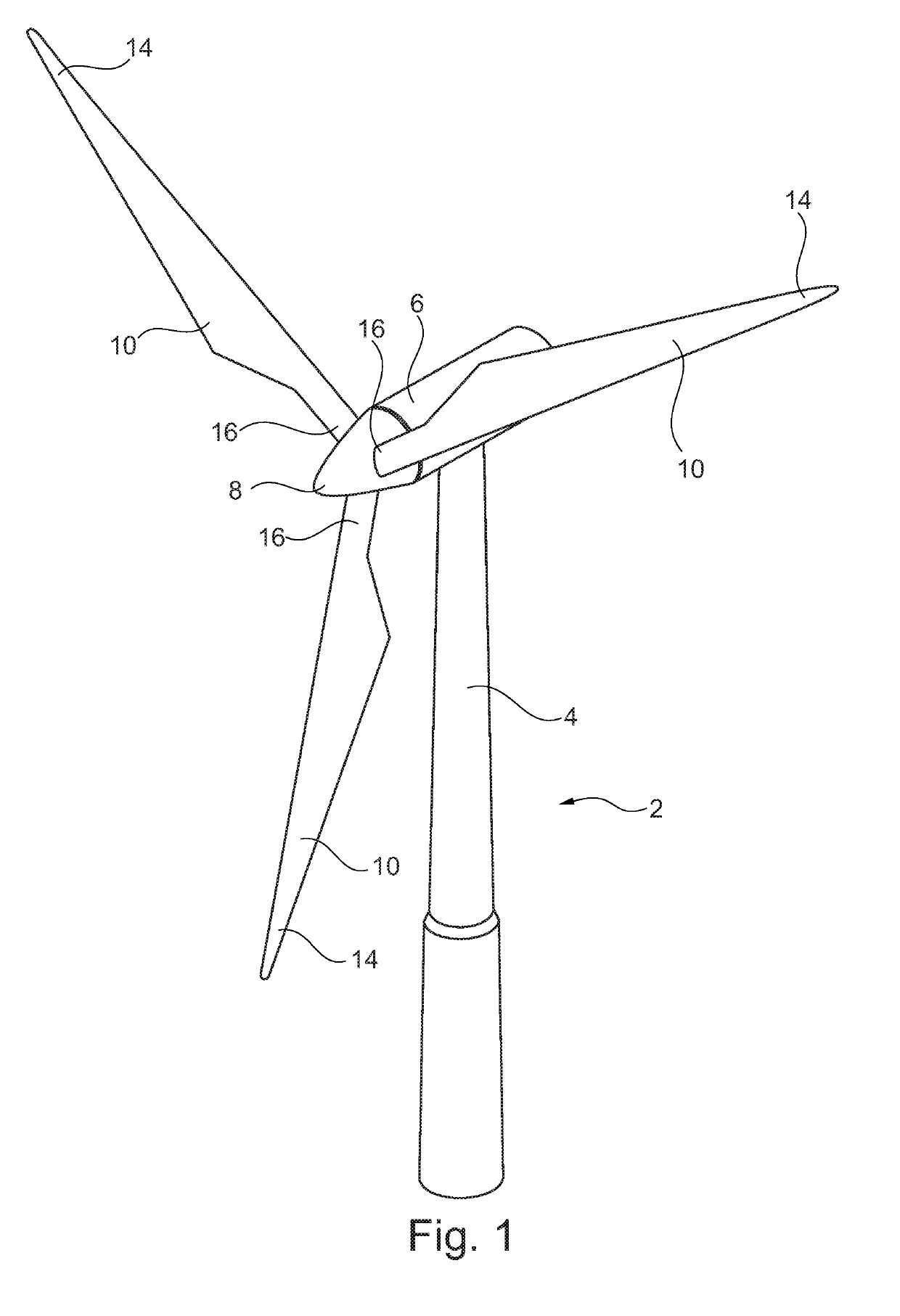

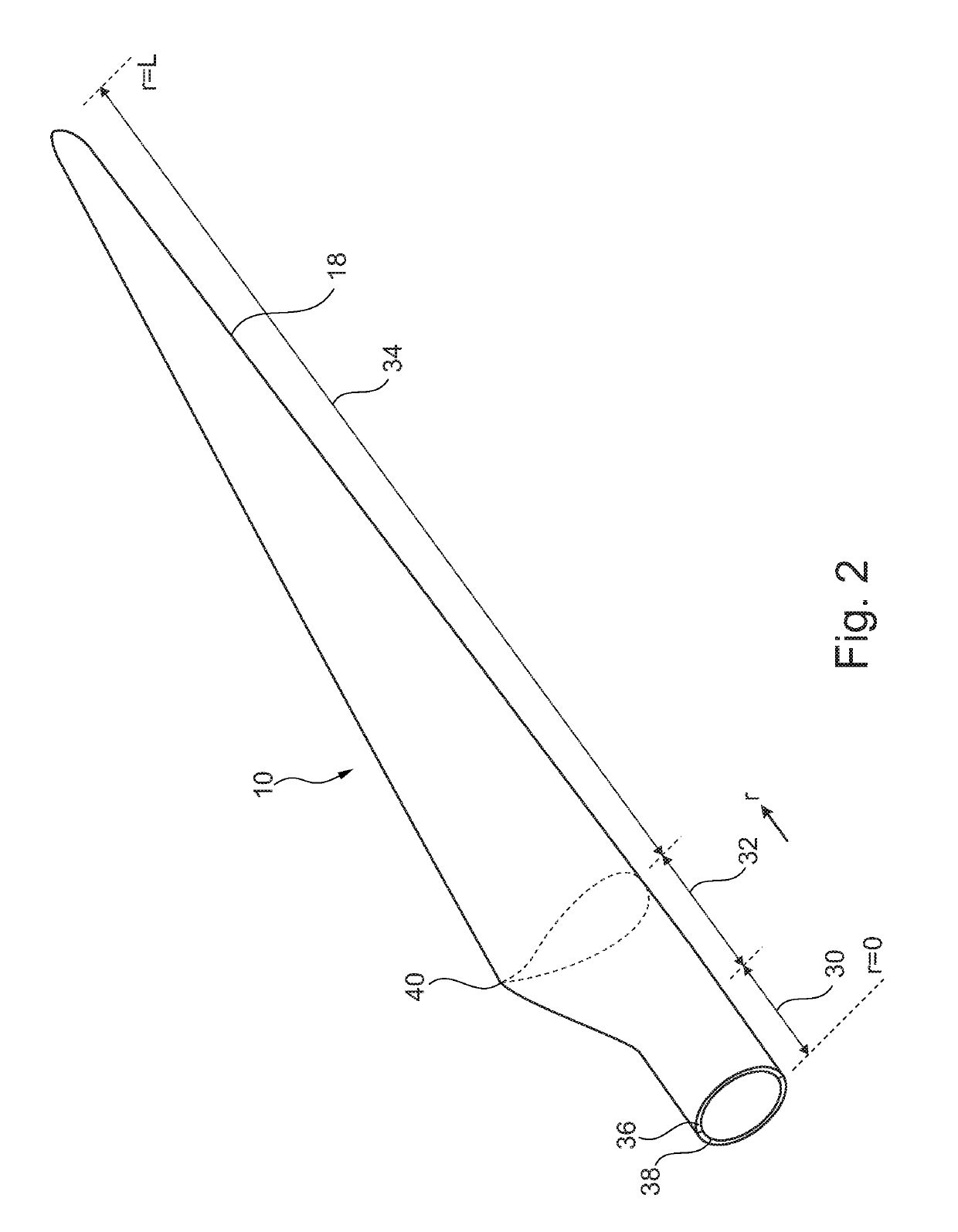

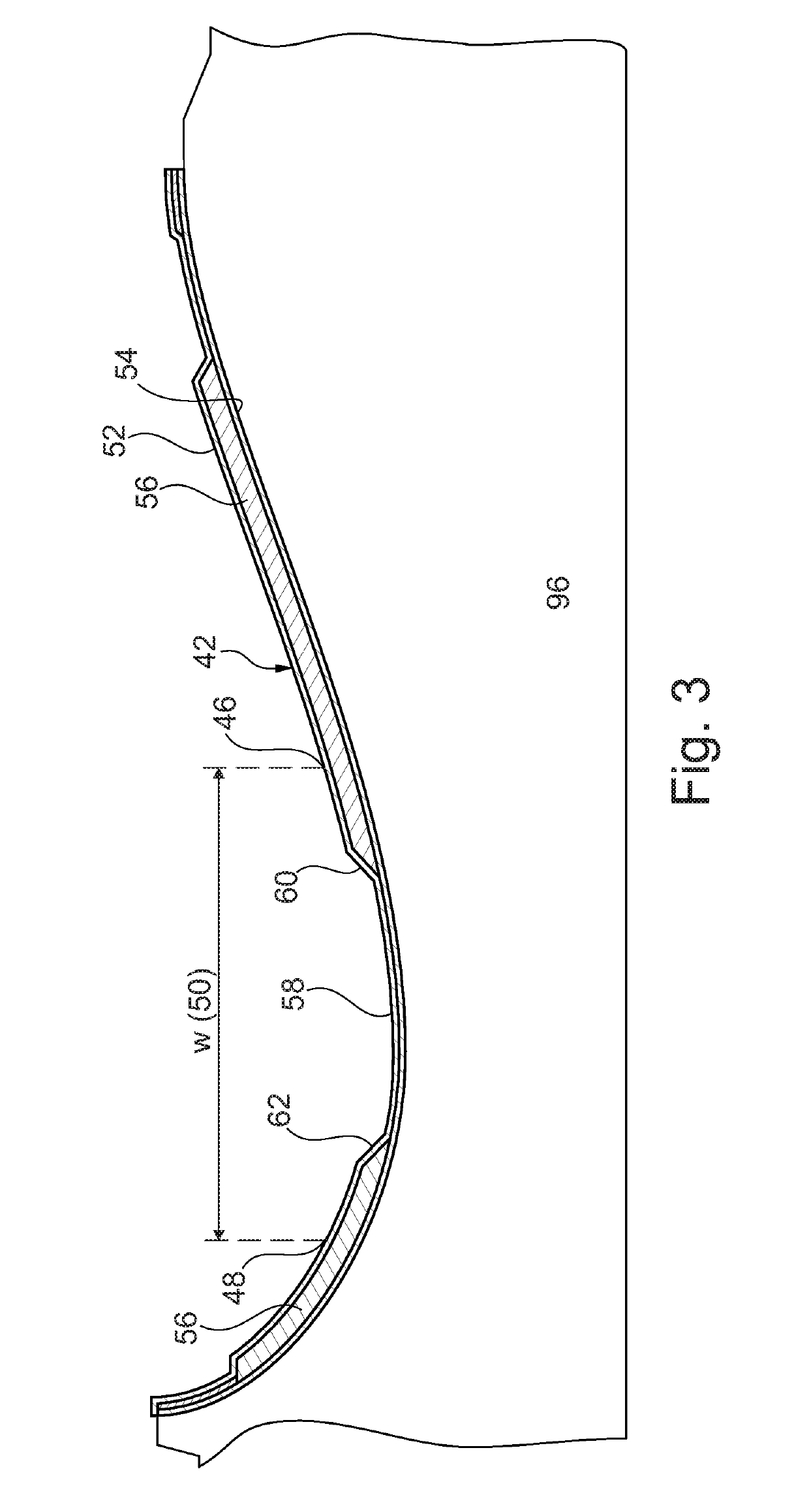

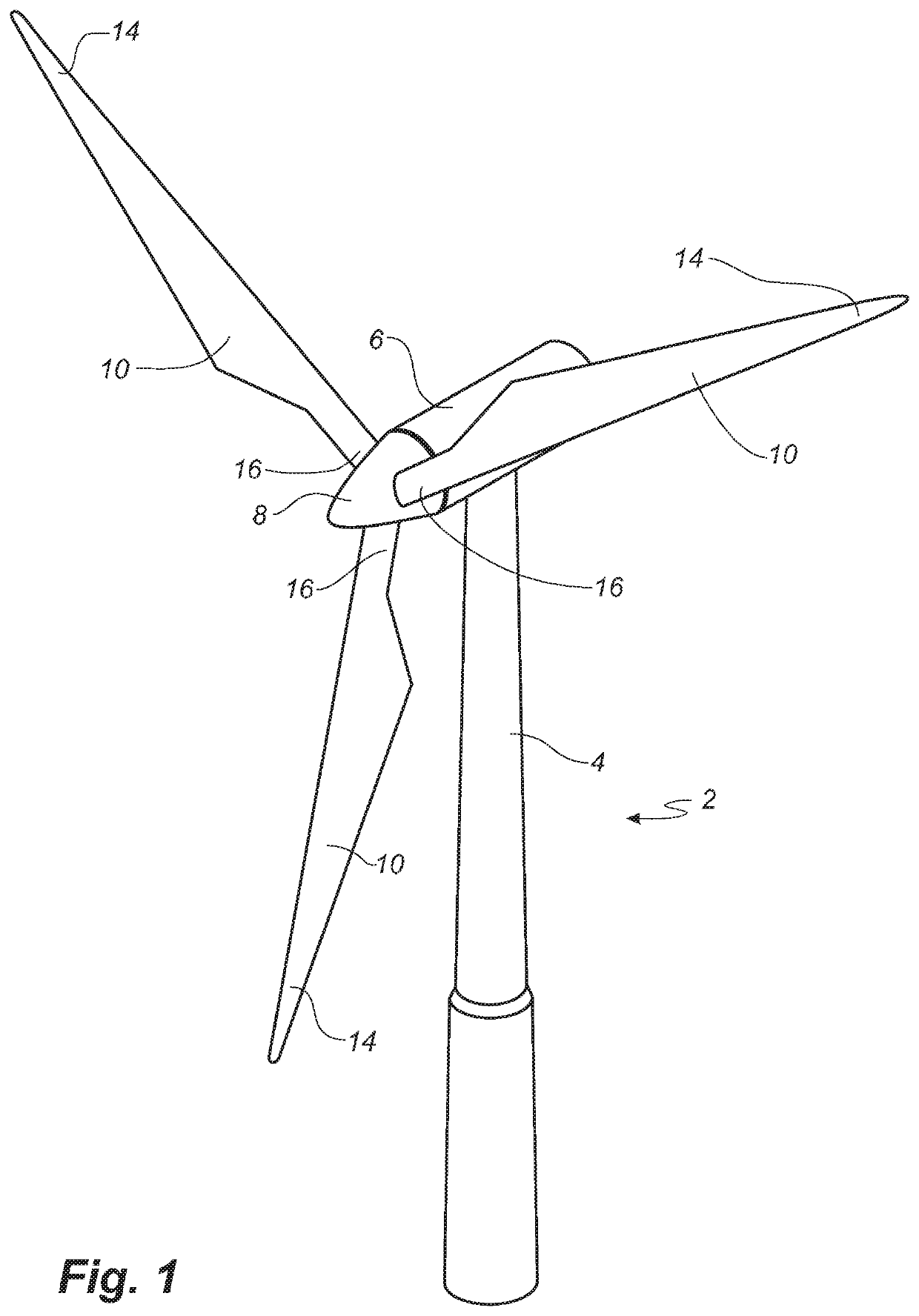

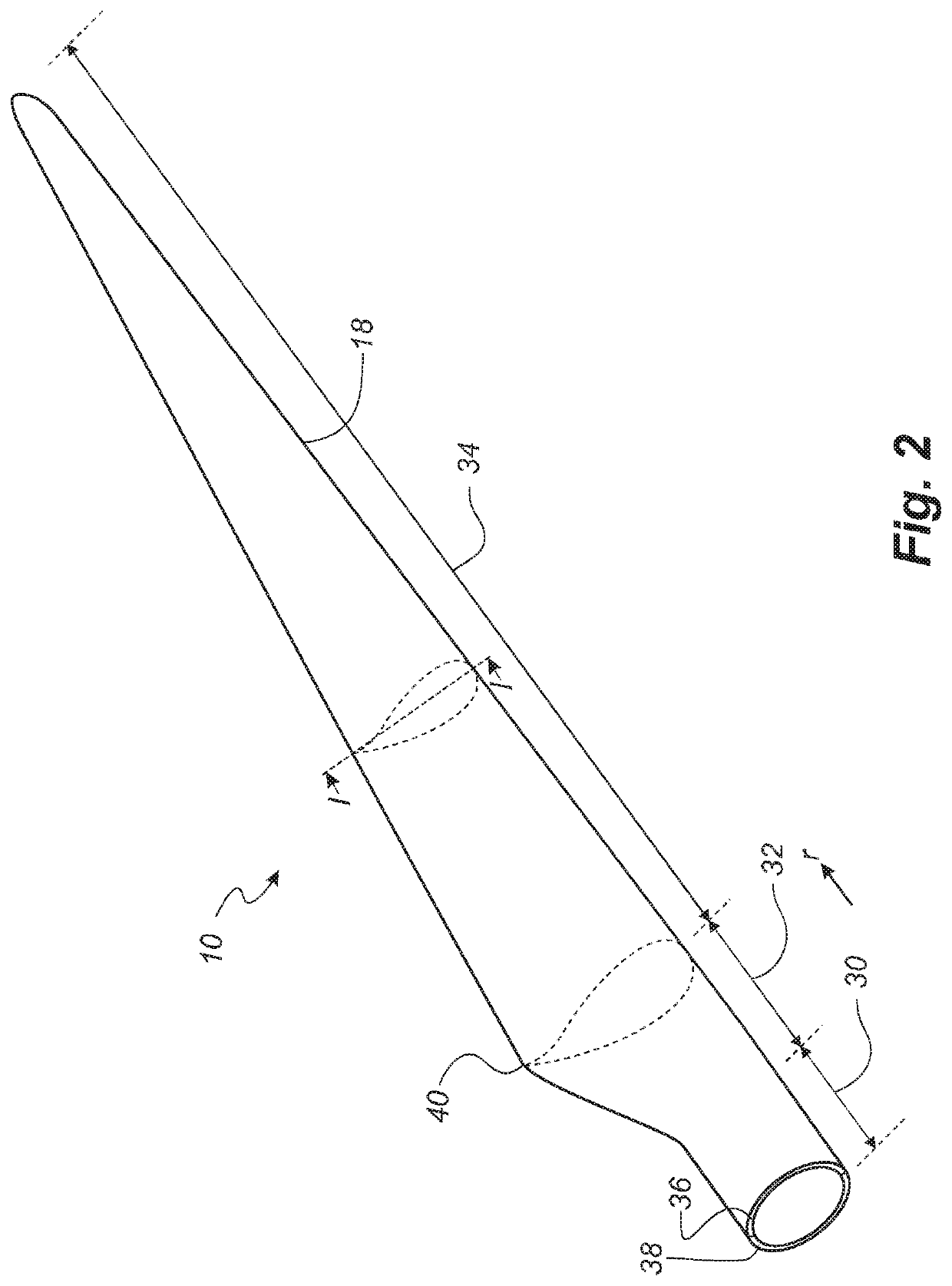

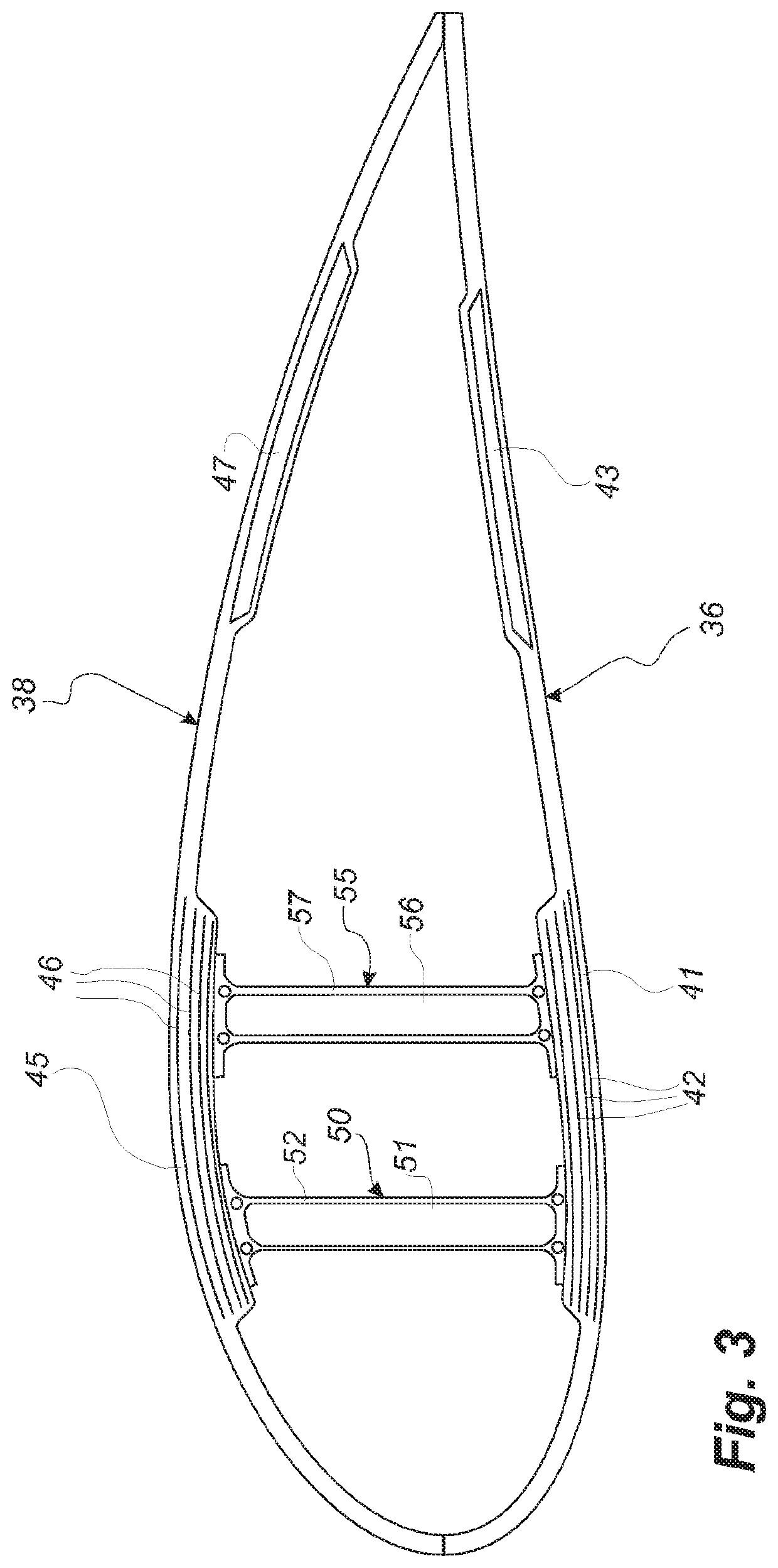

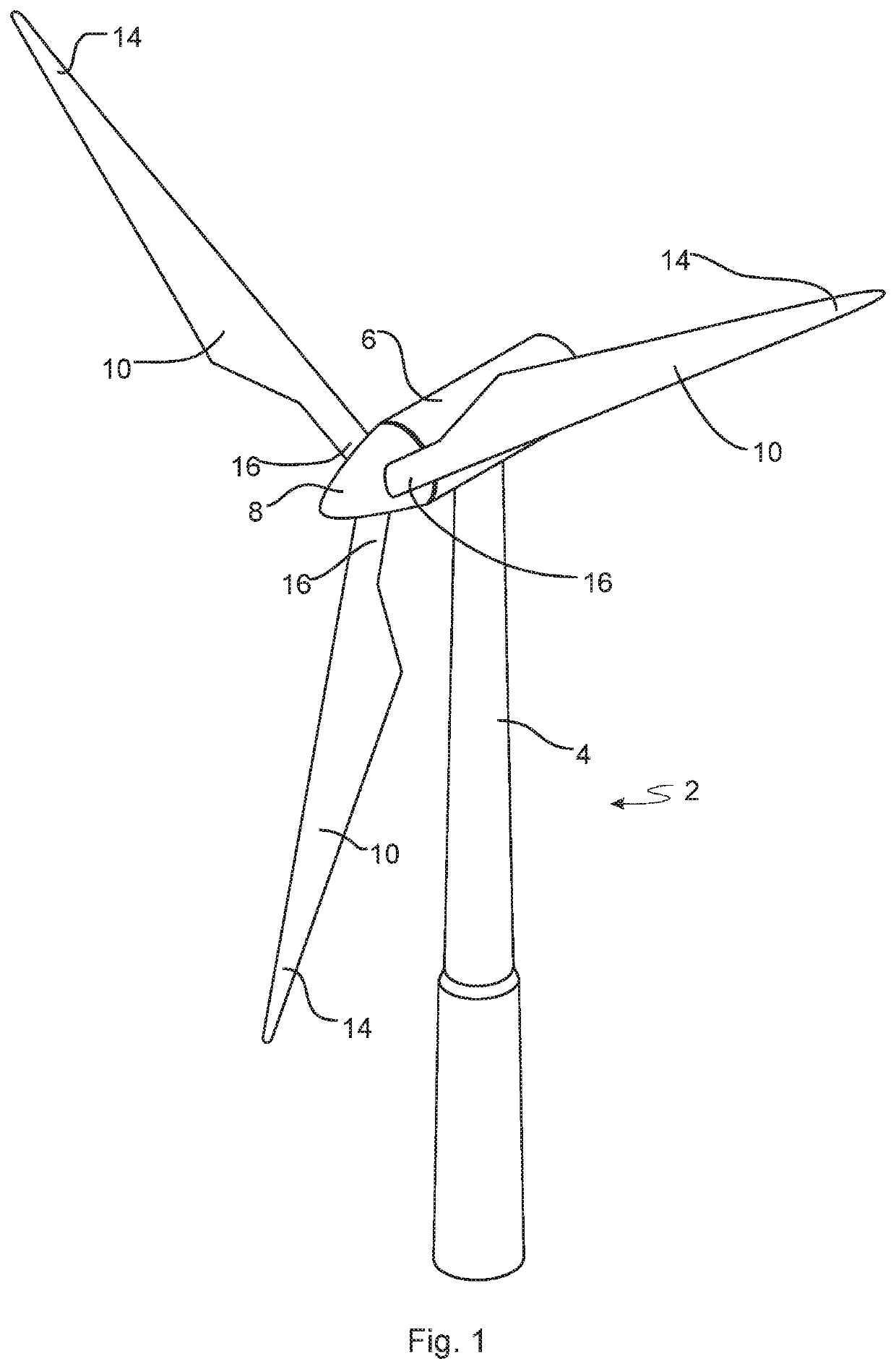

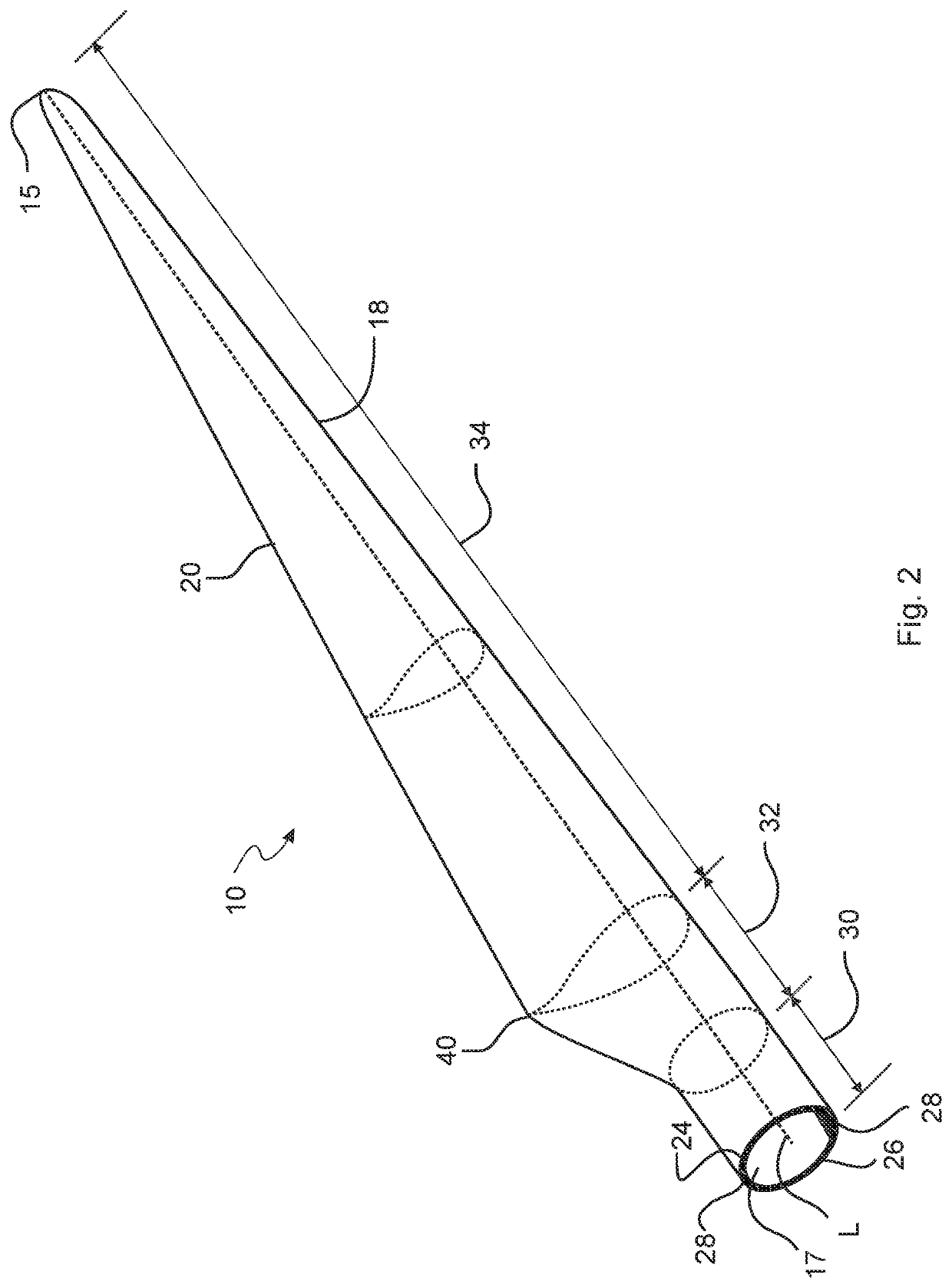

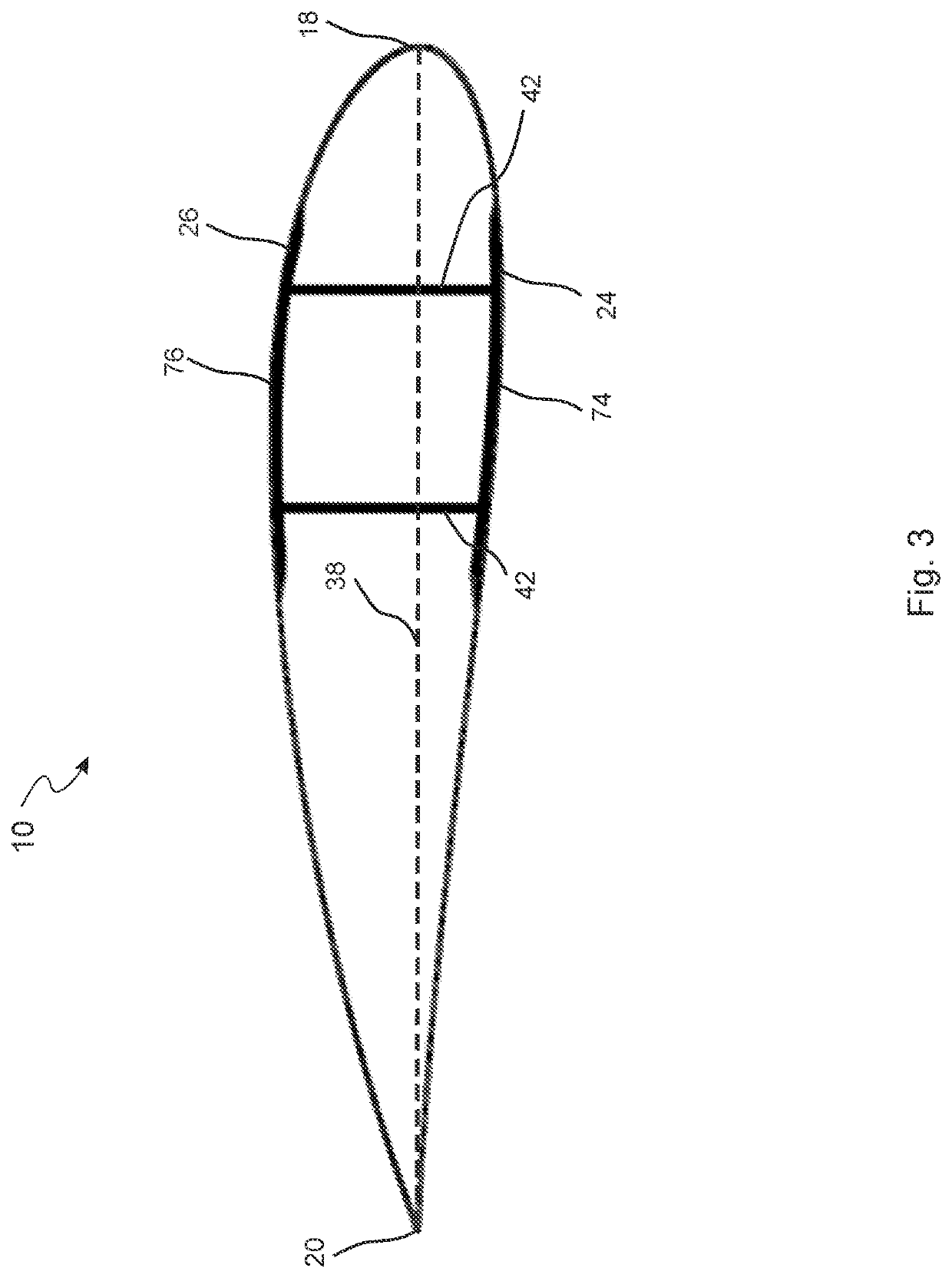

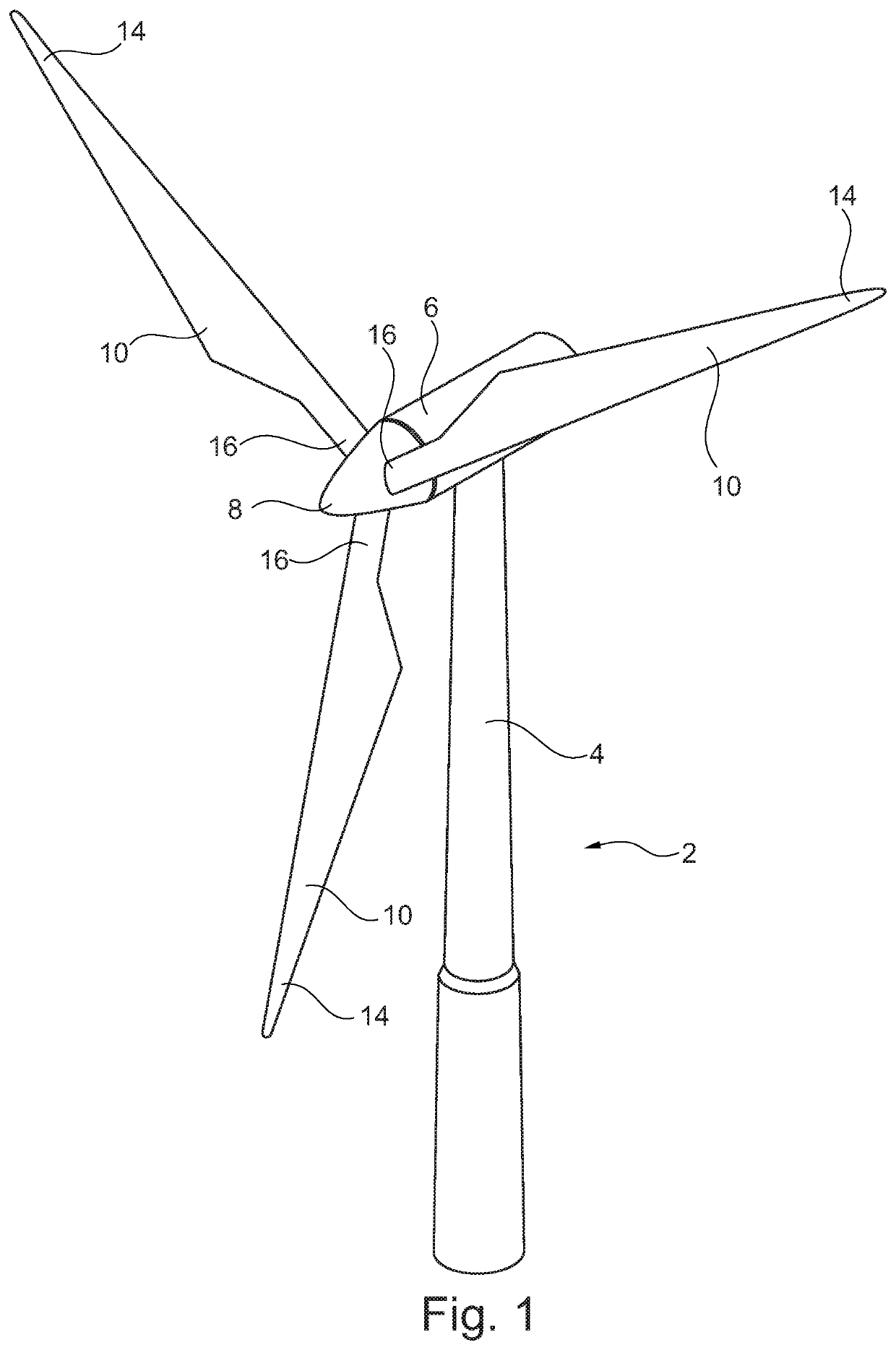

Mould and method for vacuum assisted resin transfer moulding

ActiveUS20090250847A1Reduce complexityLow costFinal product manufactureConfectioneryVacuum assistedShell molding

A mould and method for vacuum assisted resin transfer moulding of a fibre reinforced laminated structure are provided. The mould includes a first mould part and a second mould part. The first mould part defines a negative impression of the laminated structure, being structurally stable and forming a support for fibre reinforcement layers of the laminated structure. The second mould part connectable to the first mould part for closing the mould and defines together with the first mould part an enclosed space which can be evacuated. The mould further includes a flow duct for guiding a liquid polymer which is formed as a recess in the first mould part and / or a recess in the second mould part that is open towards the enclosed space and extends along a section of the periphery of the first mould part and / or the second mould part.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

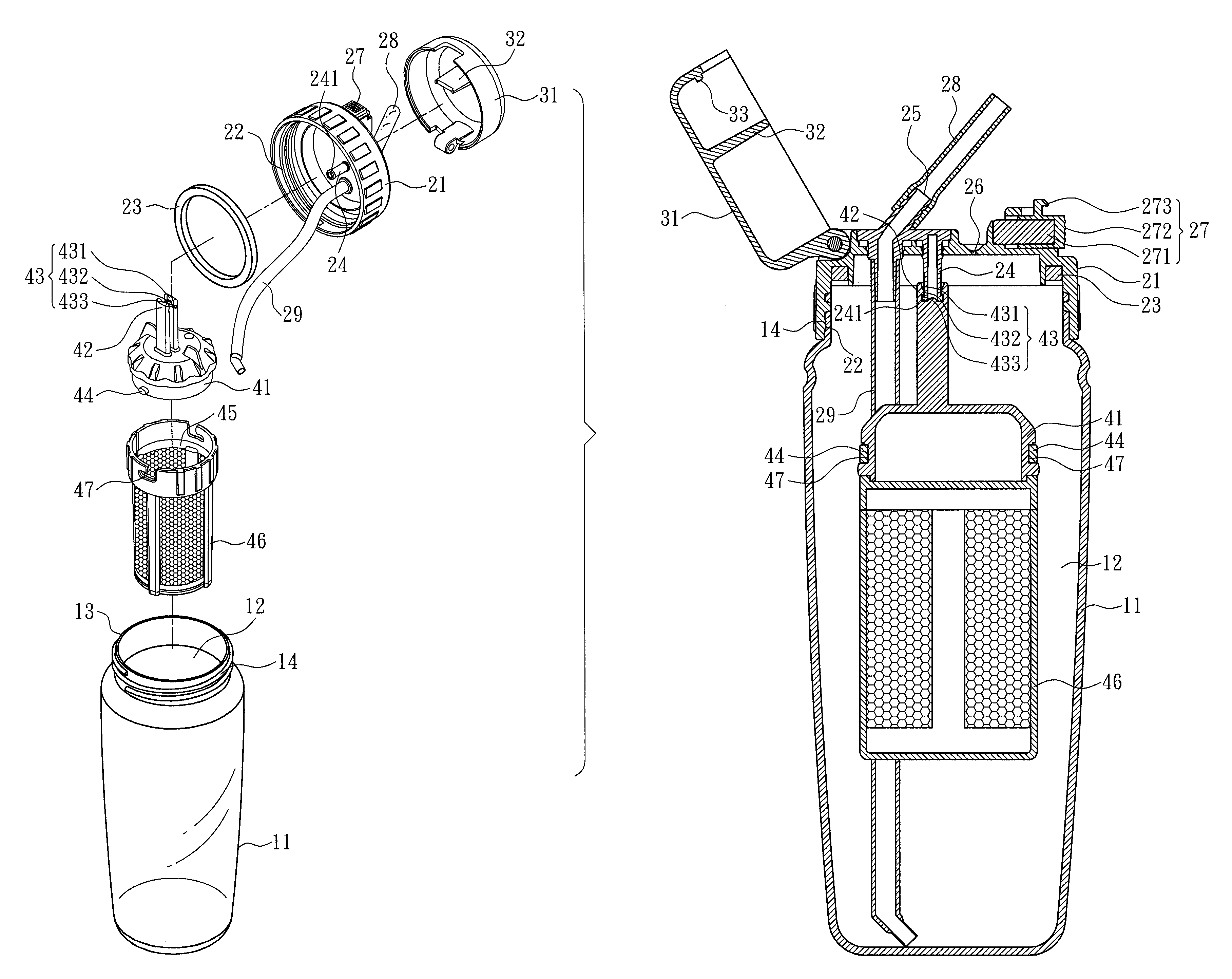

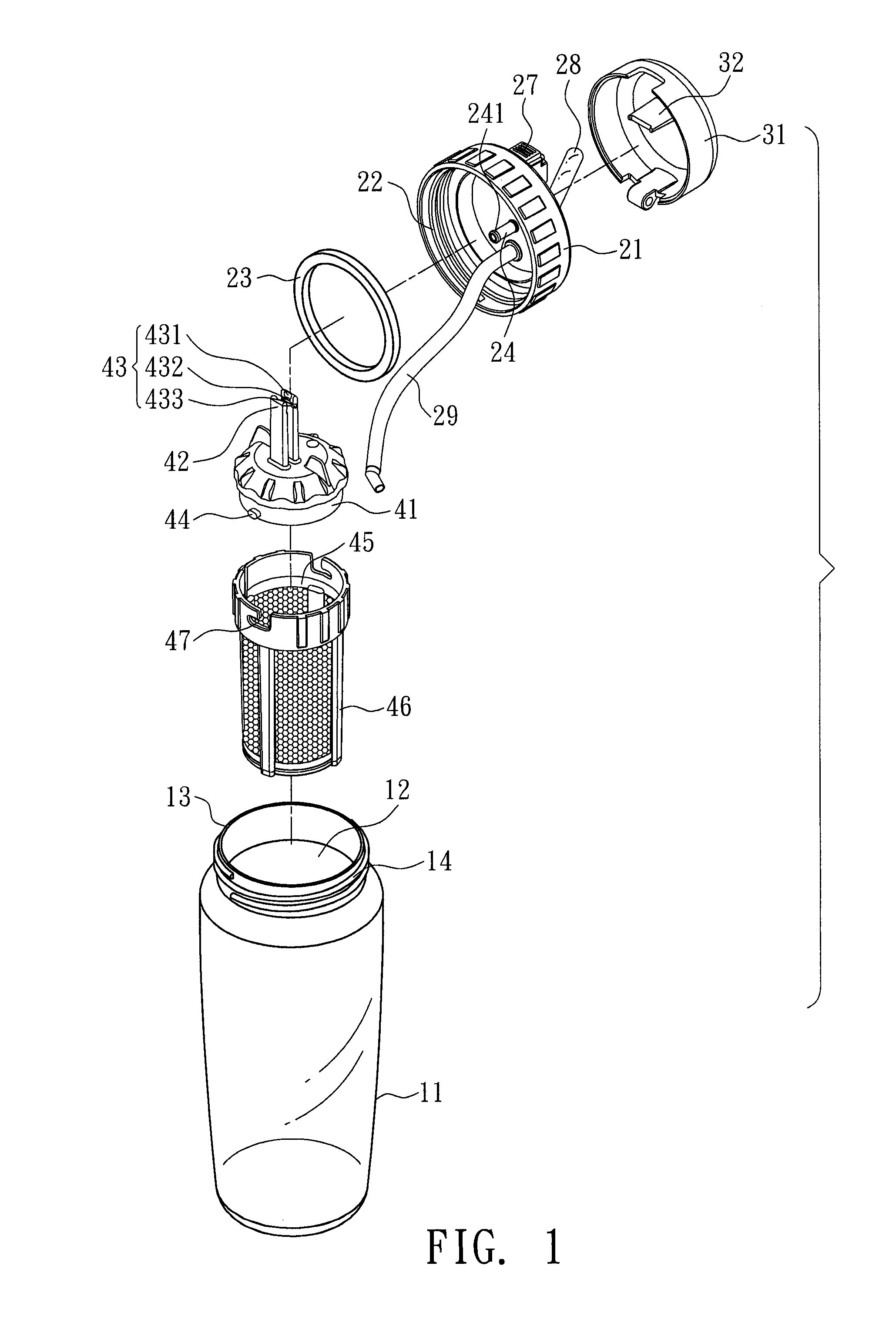

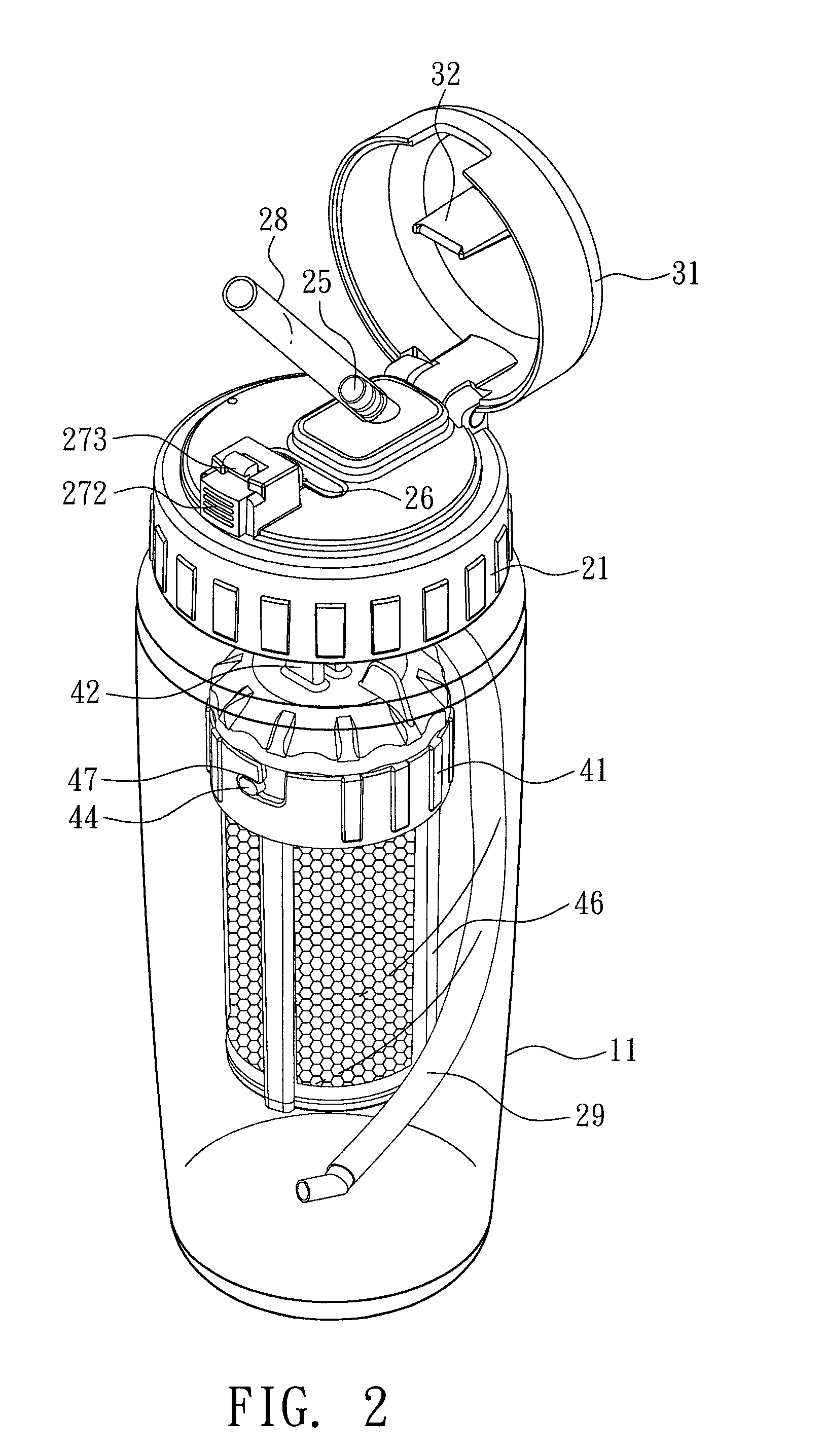

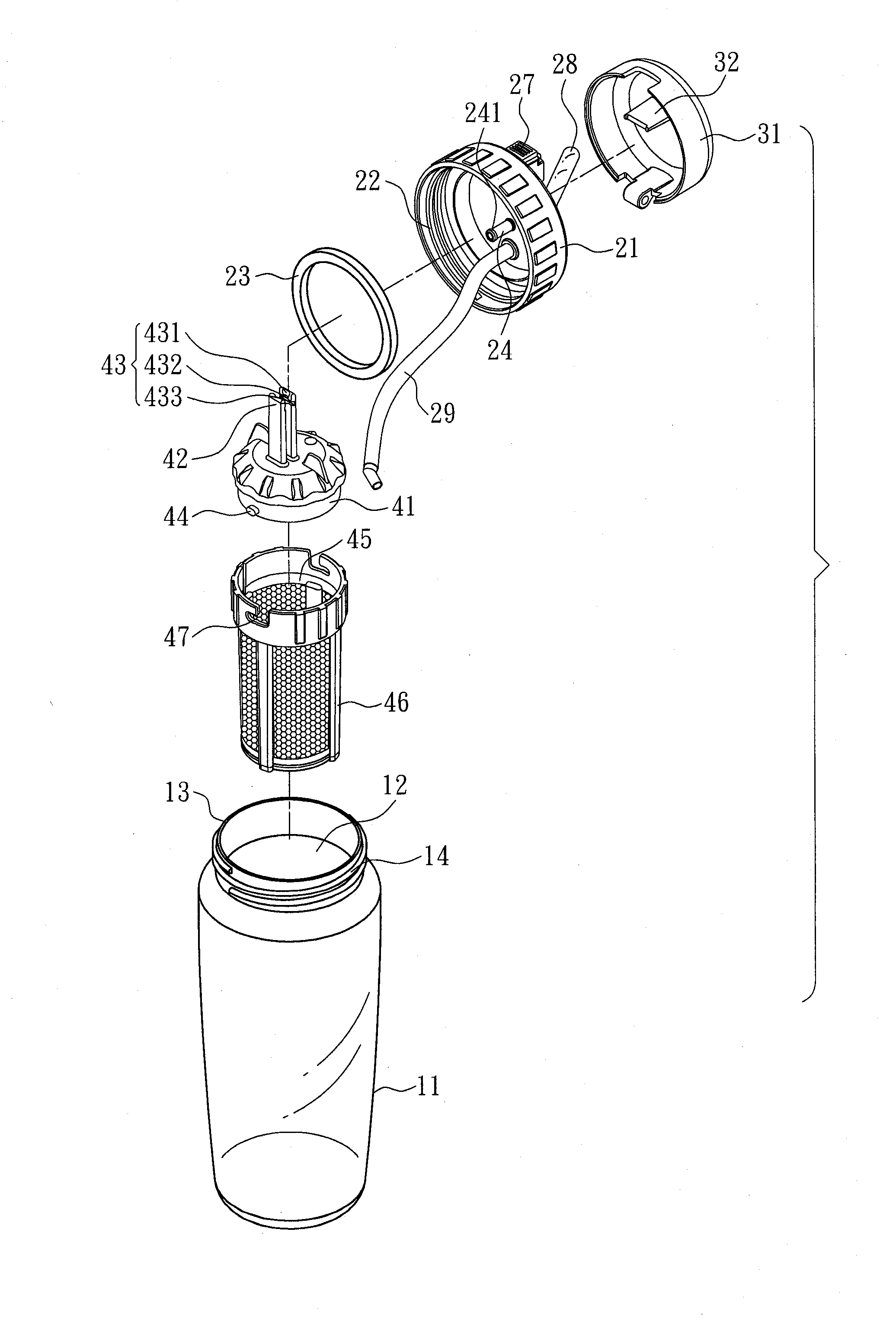

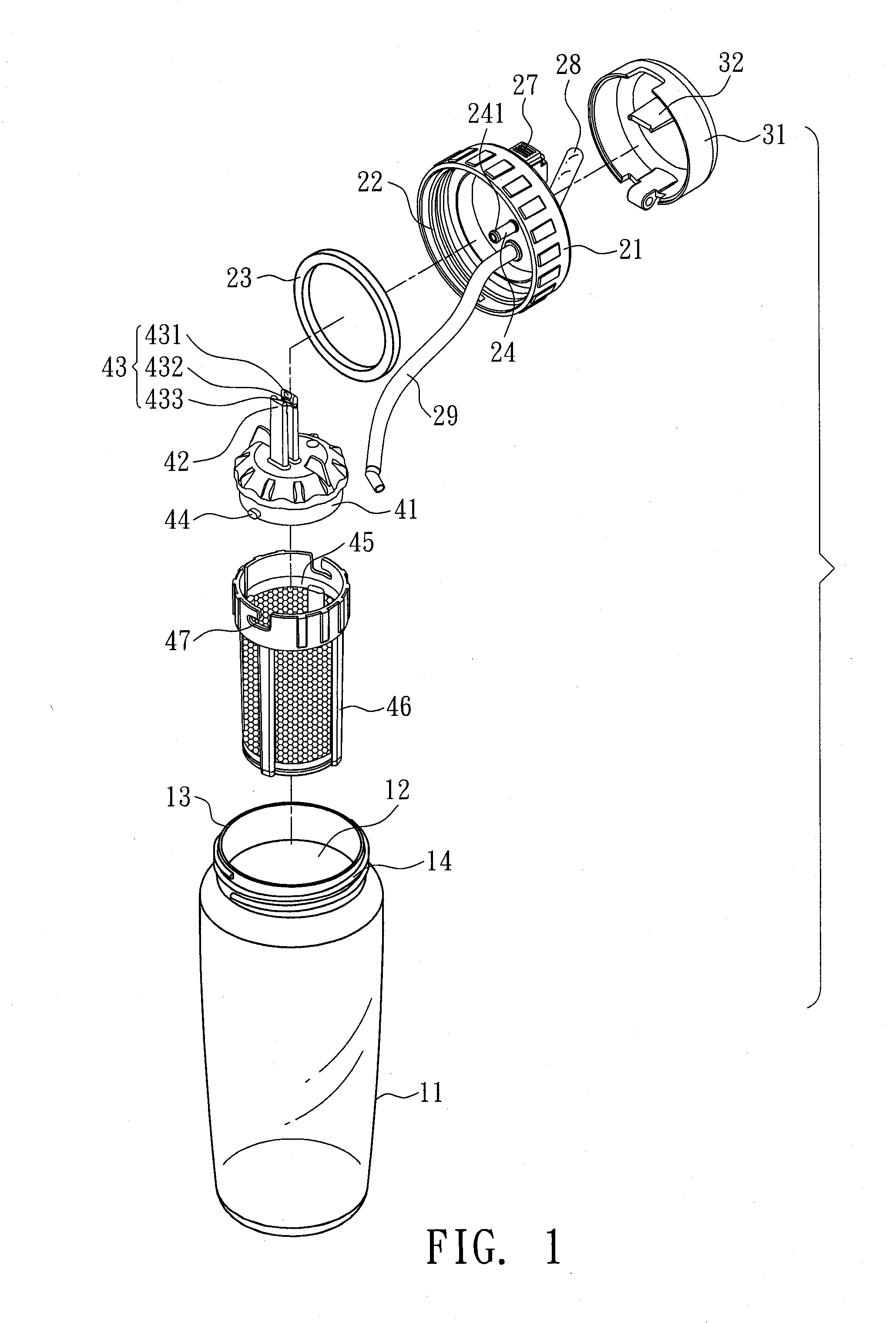

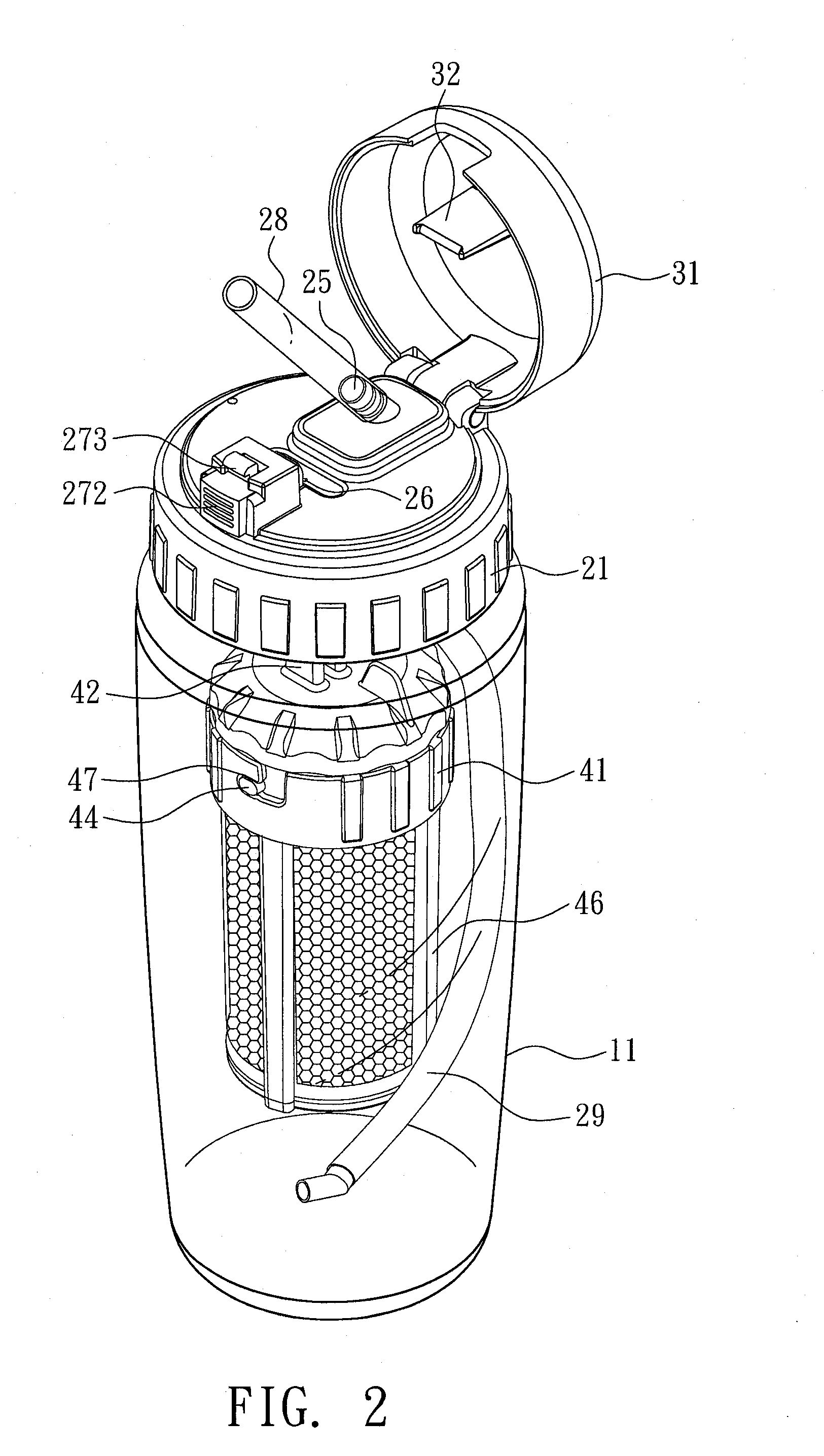

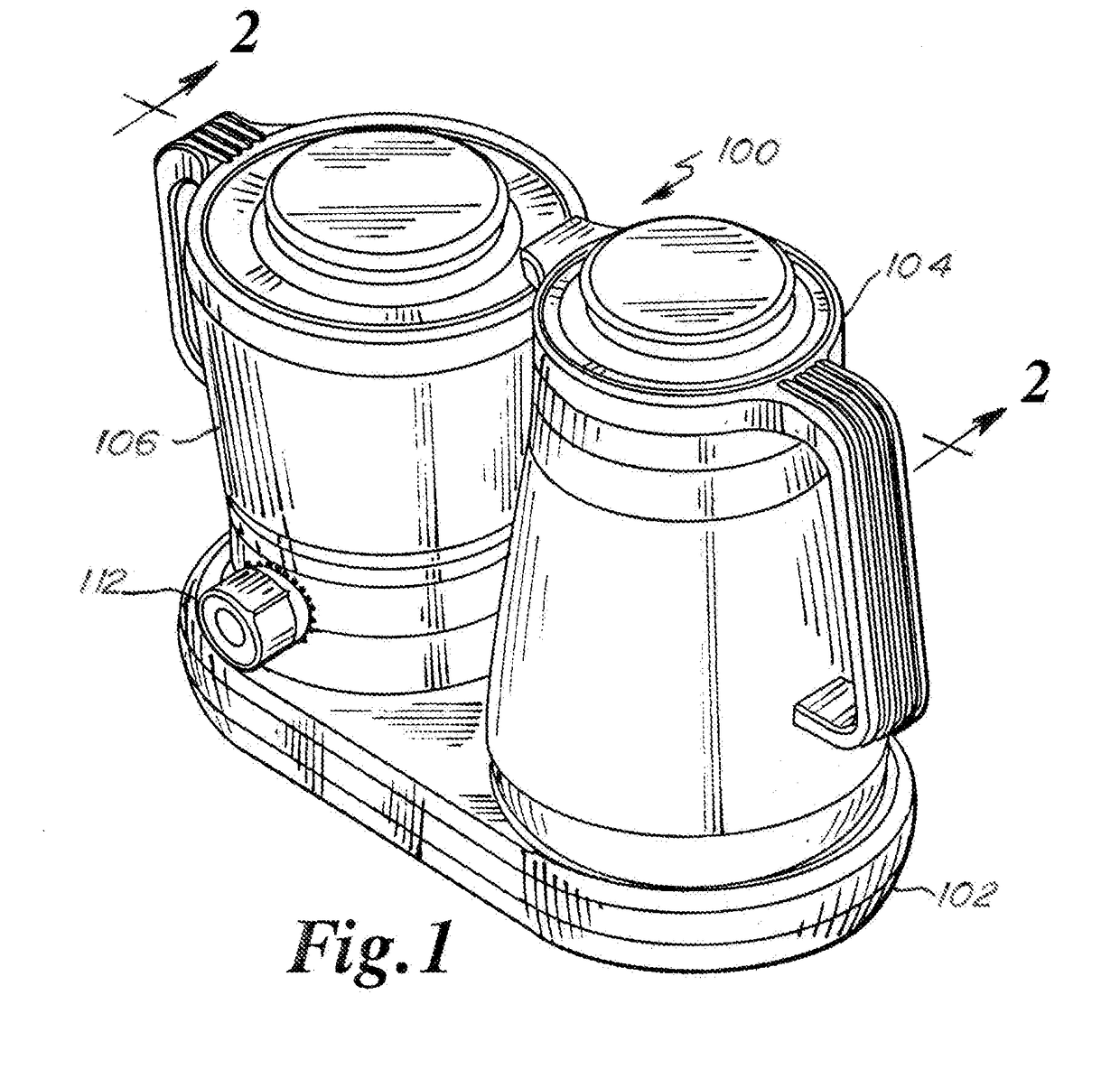

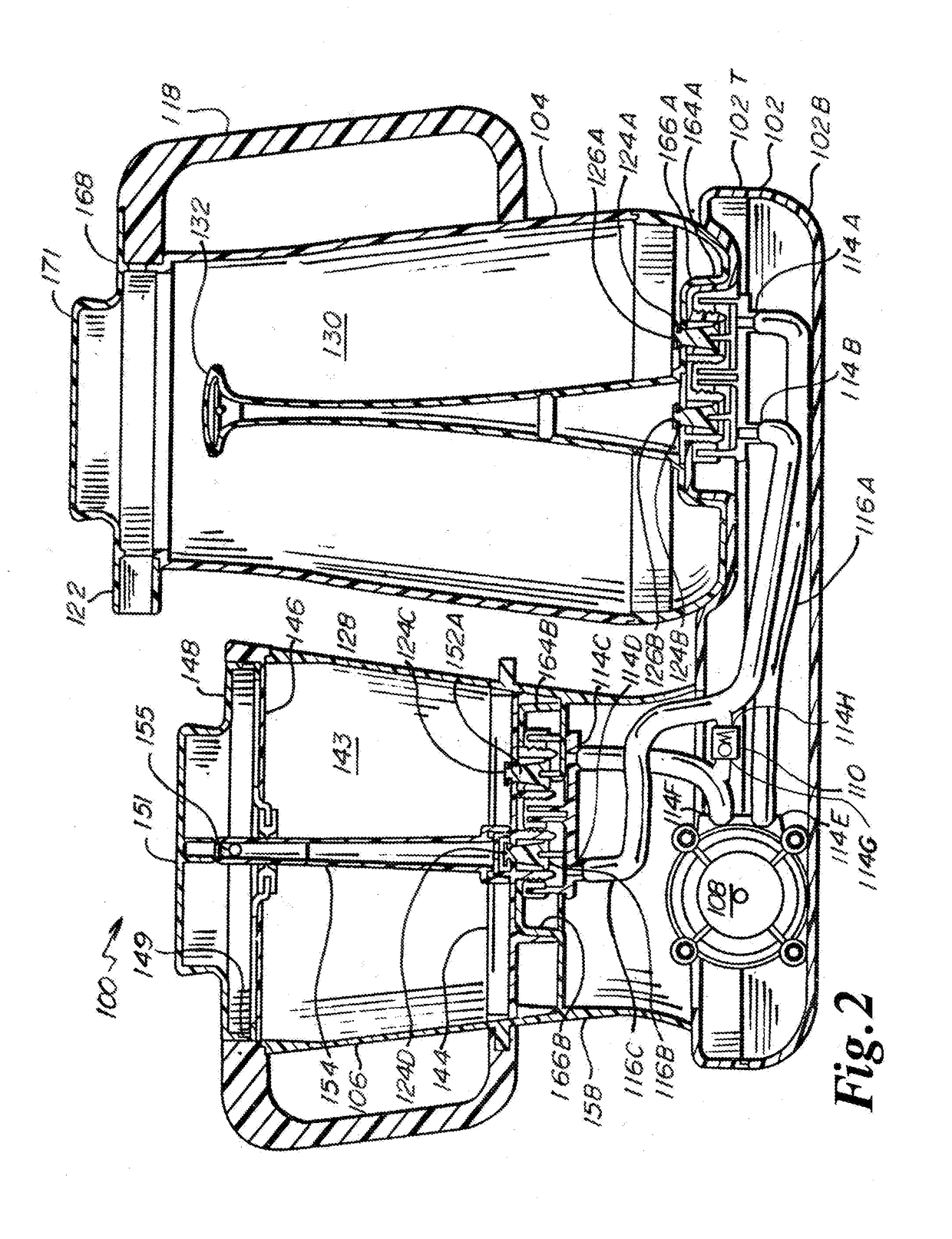

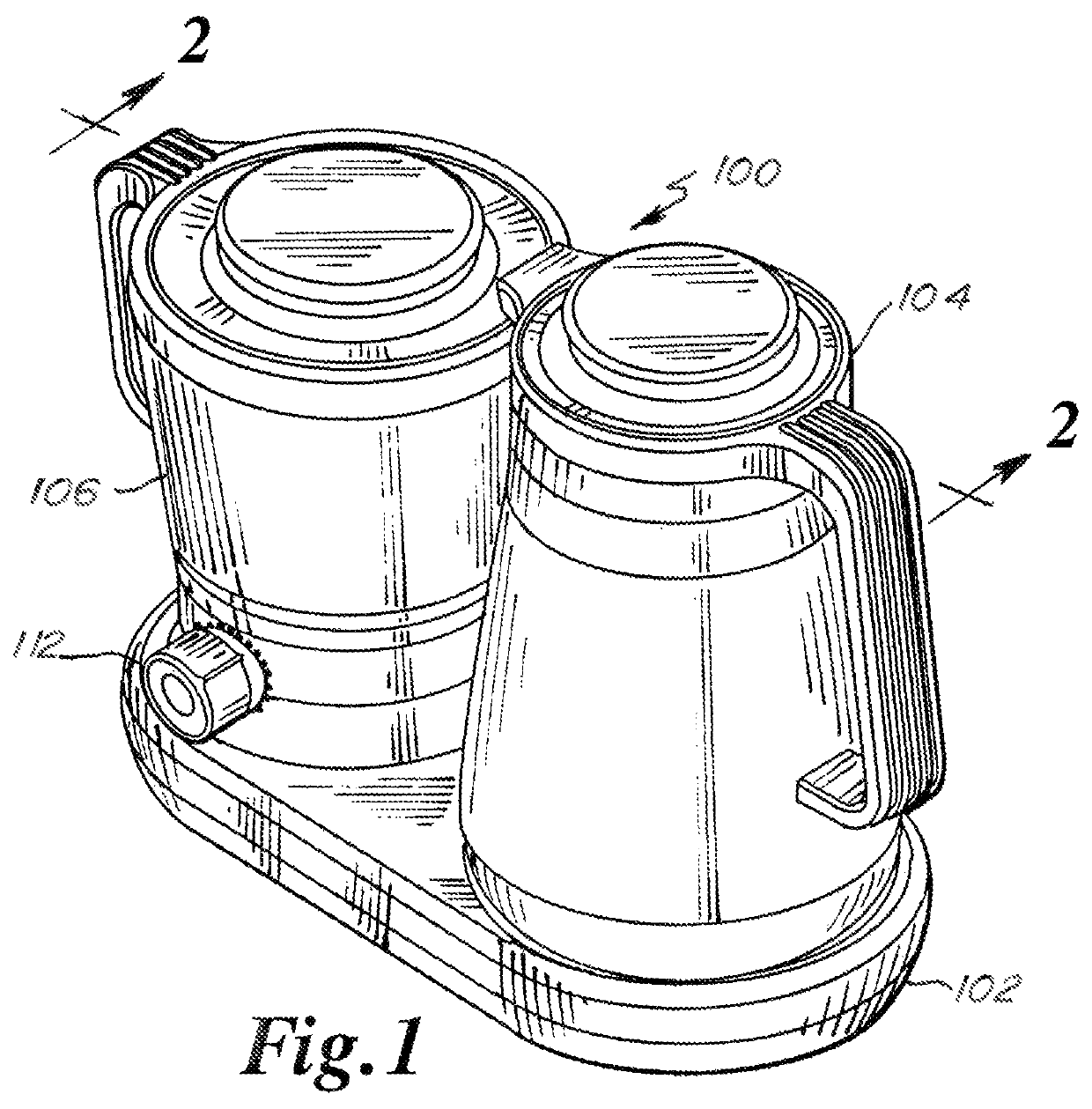

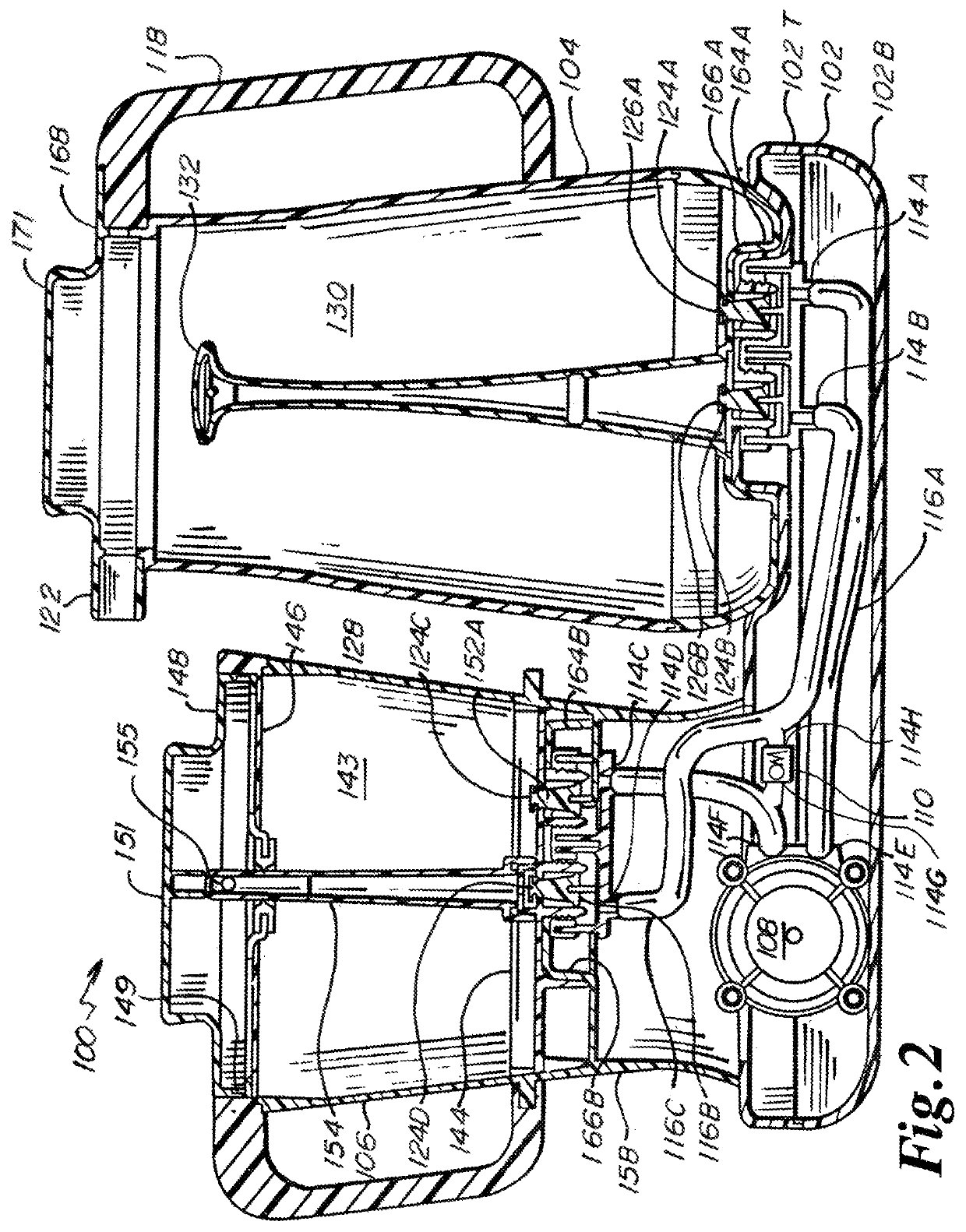

Container with an improved structure

ActiveUS8307755B2Simple structureShorten infusion timeInternal framesBeverage vesselsEngineeringMechanical engineering

A container with an improved structure includes a body having an opening. The opening is covered with a cover. The bottom of the cover has a first assembly part. A supporting base is accommodated inside the body. One end of the supporting base has a second assembly part to hang on the first assembly part. The other end of the supporting base has a connecting part for connecting with an infusion object. When the supporting base is hung on the first assembly part using its second assembly part, the supporting base can be shaken with a force.

Owner:SHEN TZU YUAN

Mould and method for vacuum assisted resin transfer moulding

ActiveUS7980840B2Reduce complexityLow costFinal product manufactureConfectioneryVacuum assistedShell molding

A mold and method for vacuum assisted resin transfer molding of a fiber reinforced laminated structure are provided. The mold includes a first mold part and a second mold part. The first mold part defines a negative impression of the laminated structure, being structurally stable and forming a support for fiber reinforcement layers of the laminated structure. The second mold part connectable to the first mold part for closing the mold and defines together with the first mold part an enclosed space which can be evacuated. The mold further includes a flow duct for guiding a liquid polymer which is formed as a recess in the first mold part and / or a recess in the second mold part that is open towards the enclosed space and extends along a section of the periphery of the first mold part and / or the second mold part.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Container with an improved structure

ActiveUS20110226133A1Improved structureShorten infusion timeInternal framesBeverage vesselsEngineeringMechanical engineering

A container with an improved structure includes a body having an opening. The opening is covered with a cover. The bottom of the cover has a first assembly part. A supporting base is accommodated inside the body. One end of the supporting base has a second assembly part to hang on the first assembly part. The other end of the supporting base has a connecting part for connecting with an infusion object. When the supporting base is hung on the first assembly part using its second assembly part, the supporting base can be shaken with a force.

Owner:SHEN TZU YUAN

Chemoradiotherapy with TS-1/camptothecins

InactiveUS20070036717A1Improve the level ofLess side effectsBiocideIn-vivo radioactive preparationsAbnormal tissue growthSide effect

An antitumor agent for chemoradiotherapy of rectal cancer comprising a combination of TS-1 (a combination drug of tegafur, gimeracil, and oteracil potassium at a 1:0.4:1 molar ratio) and CPT-11 (irinotecan hydrochloride). The antitumor agent of the invention can achieve marked tumor volume reduction without causing major side effects, especially by coadministering it with preoperative radiation therapy. The volume of even large tumors that are refractory to surgical resection can be reduced by coadministering the antitumor agent of the invention with preoperative radiation therapy, making the subsequent surgical resection of the tumor easier.

Owner:THE KITASATO INST

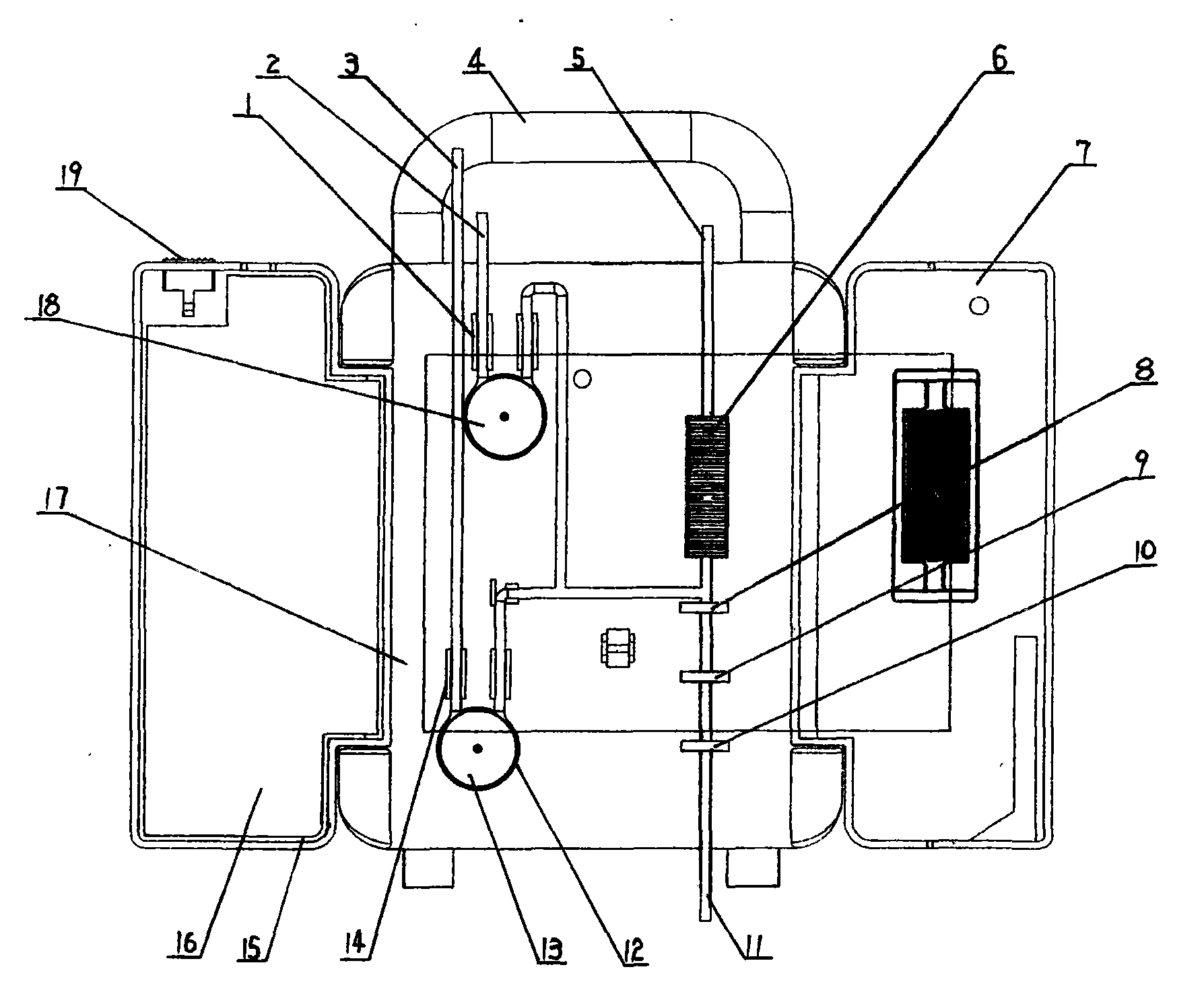

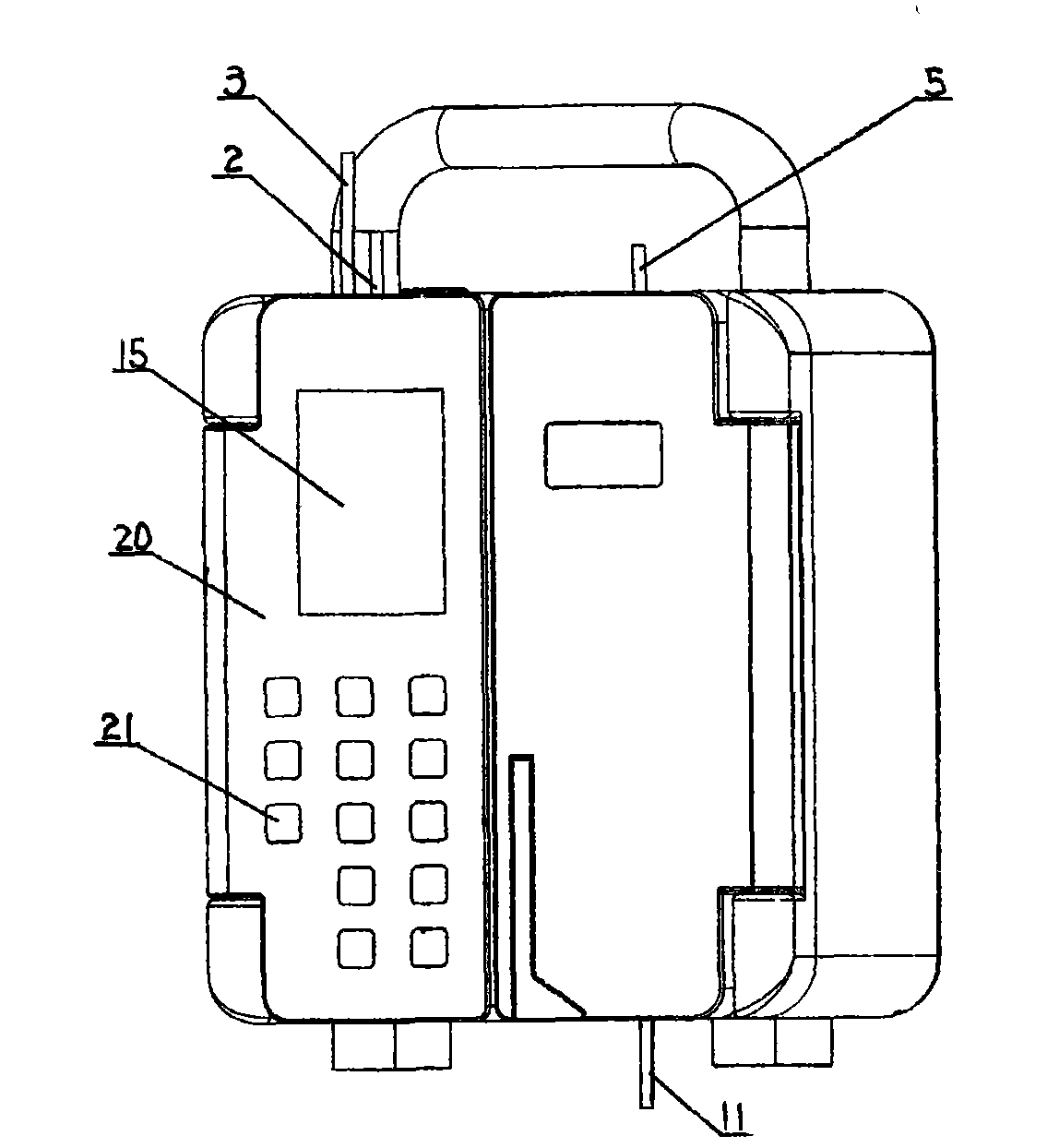

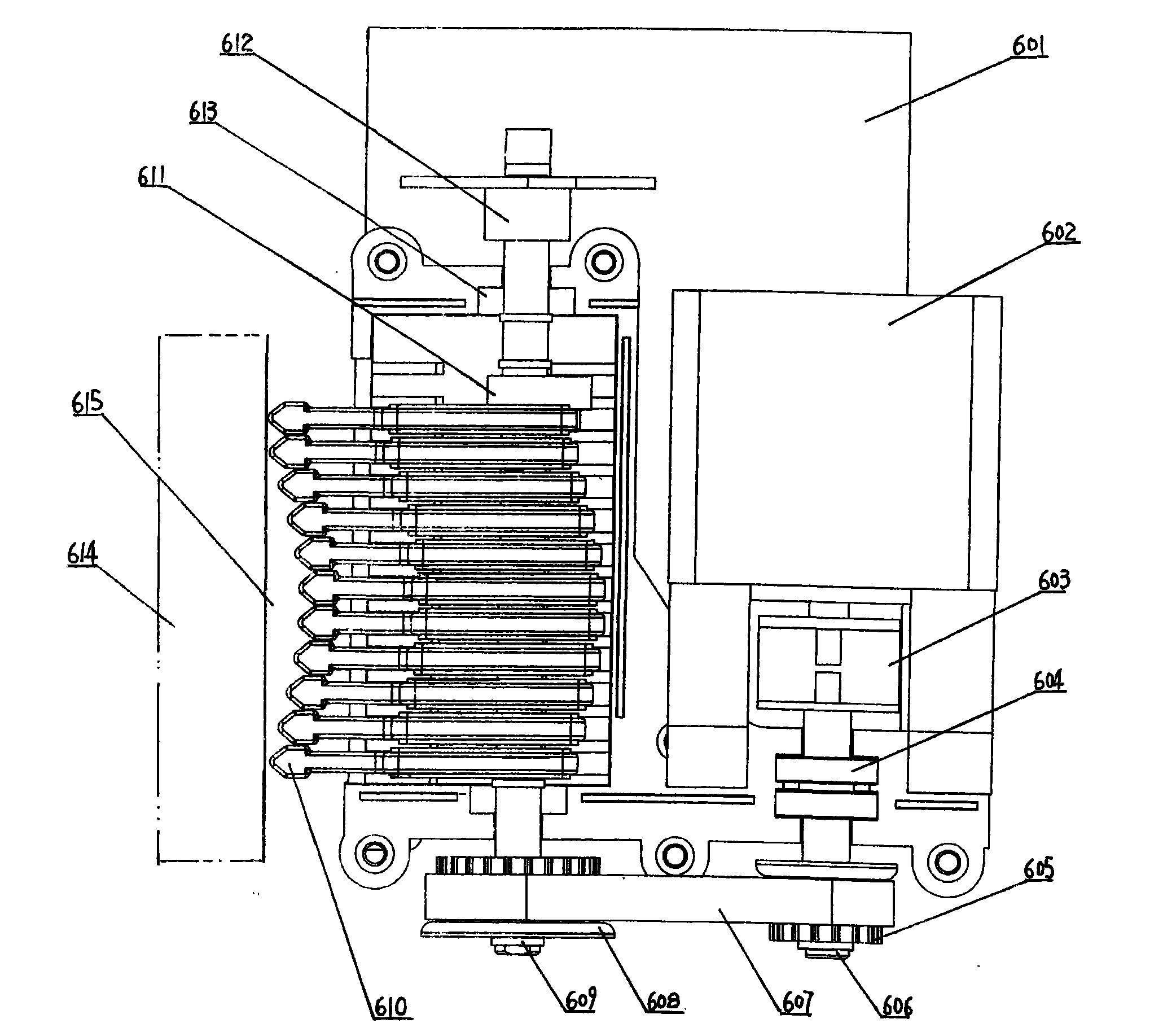

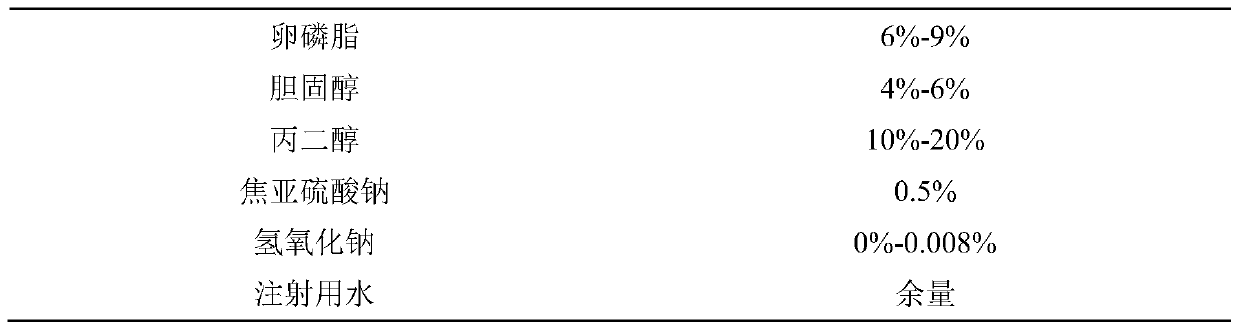

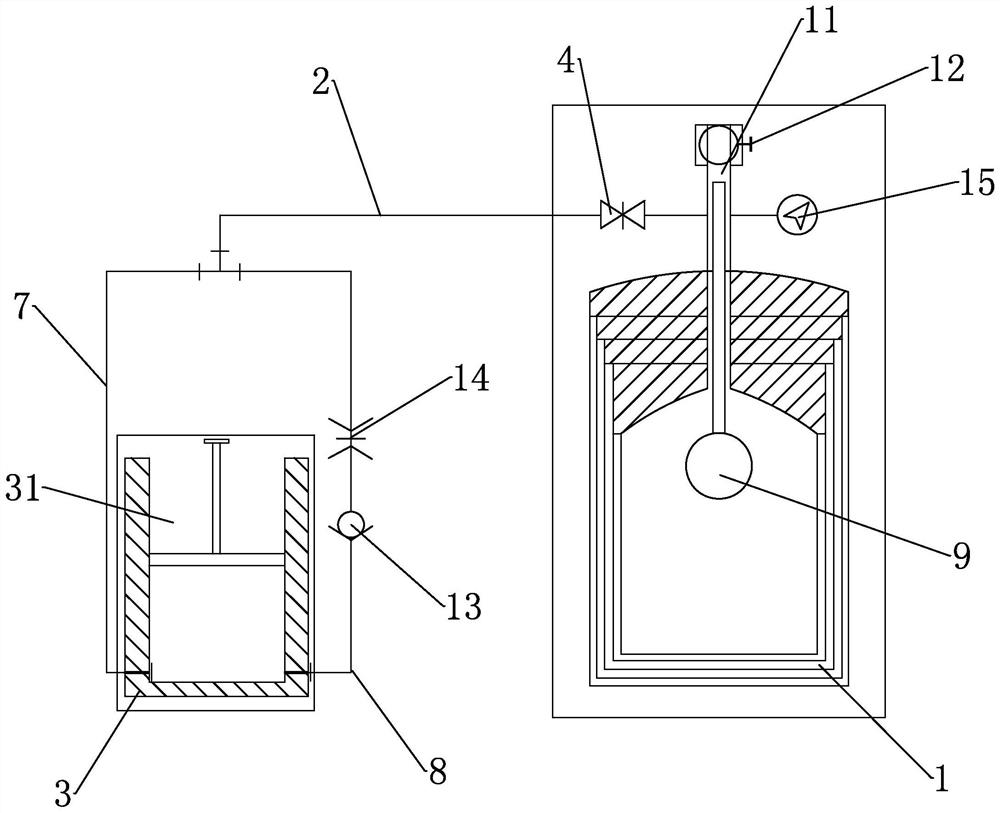

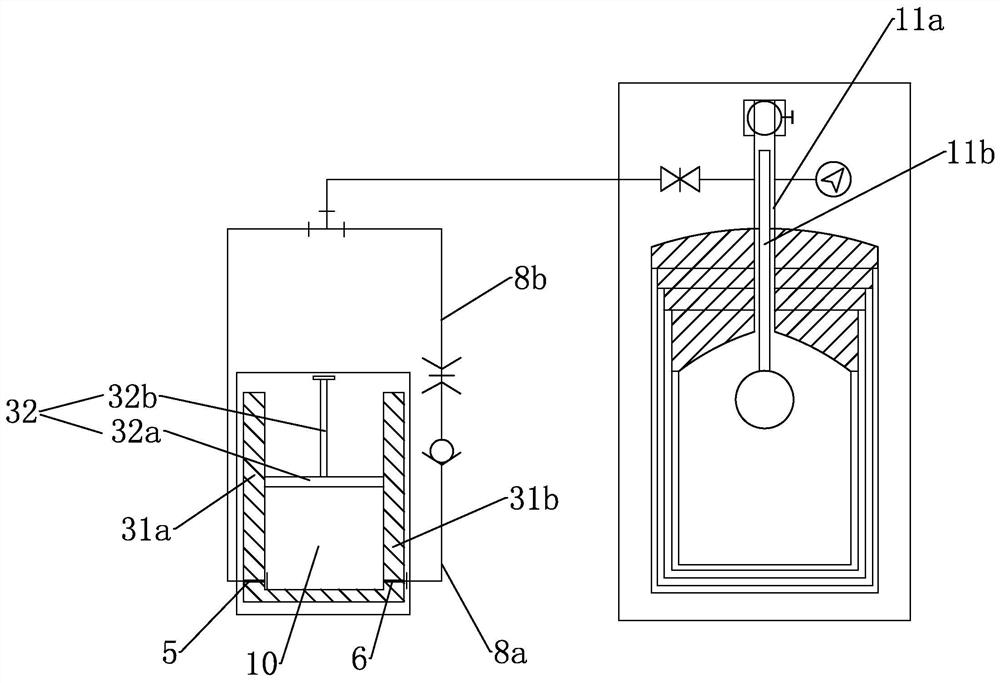

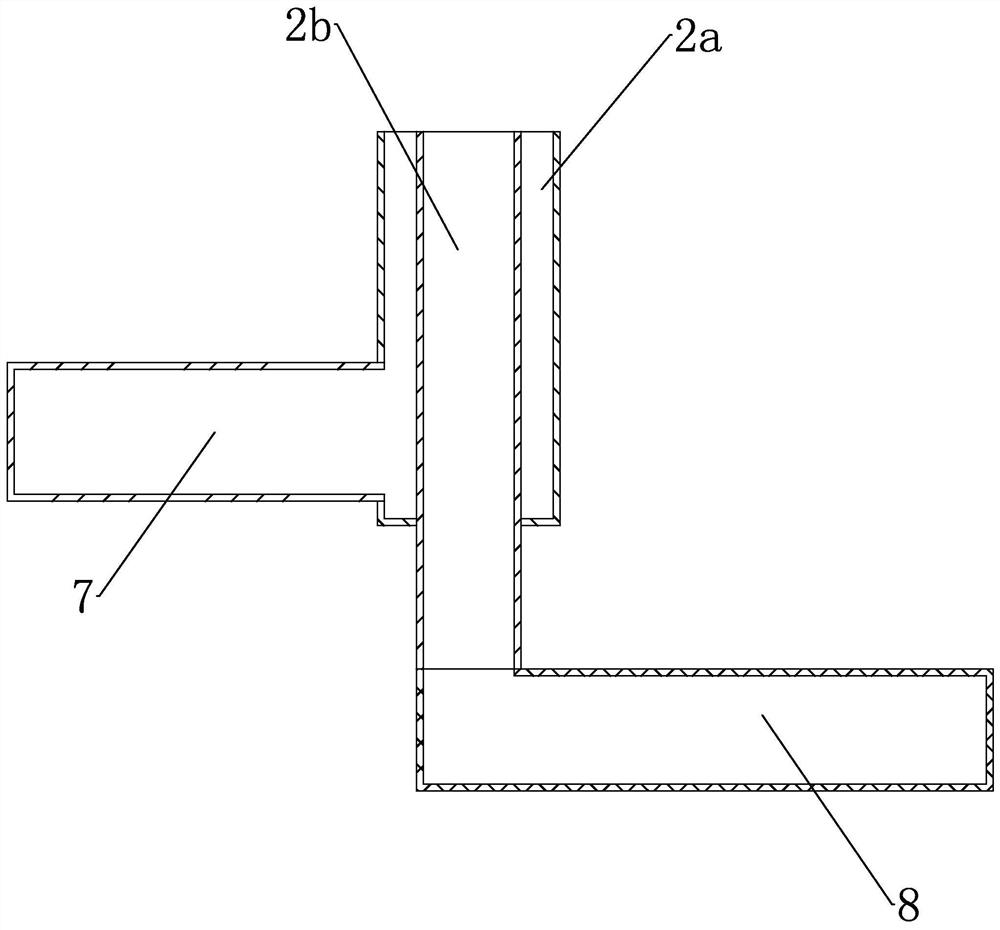

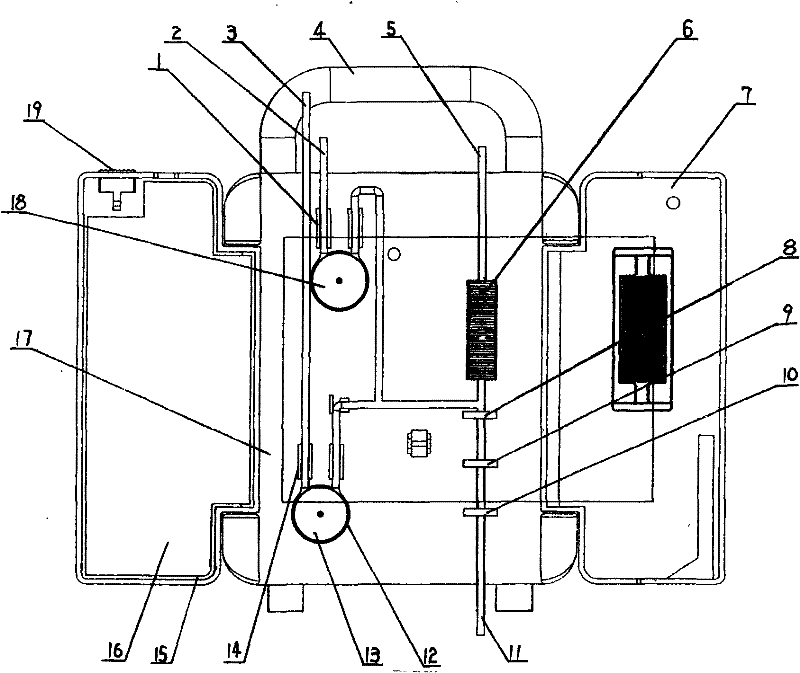

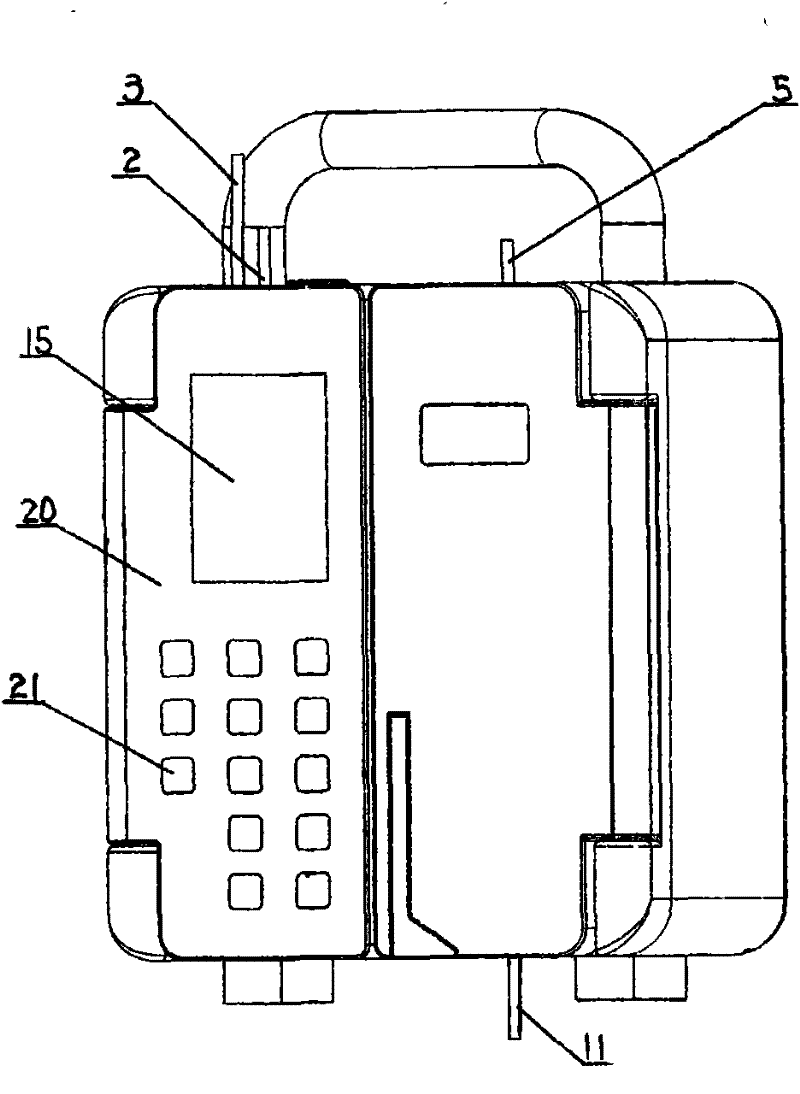

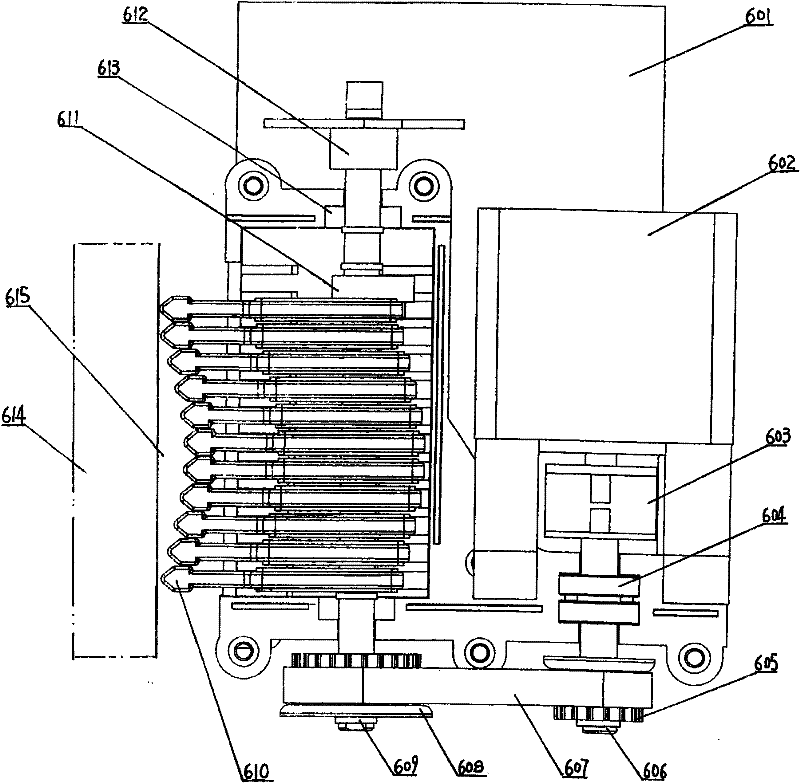

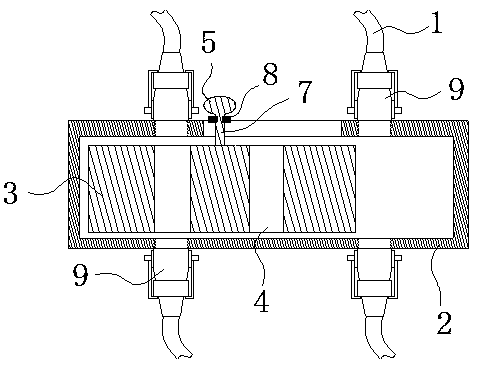

Parenteral nutrition infusion pump

ActiveCN101628137AShorten infusion timeSimple structurePressure infusionLiquid-crystal displayPN - Parenteral nutrition

The invention belongs to a parenteral nutrition infusion pump, an extrusion device which respectively extrudes three infusion tubes is arranged in a housing, a fixing slot for fixing the three infusion tubes is arranged in the housing, a bubble detector, a pressure detector and a liquid stopping clip are arranged on the housing at the output end of the infusion tubes, a left housing cover and a right housing cover which are opened to two sides are arranged at the upper end of the housing, and a liquid crystal display screen and a control keyboard are arranged on one housing cover. The parenteral nutrition infusion pump can rapidly and safely complete the three-channel infusion process and have the advantages of simple structure, time-saving and effort-saving properties, safety, sanitation, convenient use and good effect.

Owner:SHANDESHI MEDICAL TECH BEIJING

Method of manufacturing a composite laminate structure

ActiveUS20190039337A1Provide usageRisk minimizationEngine manufactureFinal product manufactureVacuum assistedCarbon fibers

The present disclosure provides a method of manufacturing a composite laminate structure of a wind turbine blade part by means of resin transfer moulding, preferably vacuum-assisted resin transfer moulding. In a resin transfer moulding, fibre-reinforcement material is impregnated with liquid resin in a mould cavity. The mould cavity comprises rigid mould part having a mould surface defining a surface of the wind turbine blade part.The method comprises alternately stacking on the rigid mould part:i. a number of unidirectional fibre-reinforcement layers comprising electrically conductive fibres, such as carbon fibres, andii. a flow-enhancing fabric layer for enhancing a flow of the resin during infusion of the fibre-reinforcement layers, the flow-enhancing fabric layer comprising an open-structured layer made of a first material, wherein the flow-enhancing fabric layer comprises a longitudinal direction and a transverse direction,The flow-enhancing fabric layer further comprises filaments or bundles of fibres made of a second material, which is an electrically conductive material and which are arranged and configured to provide a conductive path from first electrically conductive fibres of a first fibre-reinforcement layer on a first side of the flow-enhancing layer to second electrically conductive fibres of a second fibre-reinforcement layer on a second side of the flow-enhancing layer.

Owner:LM WP PATENT HLDG

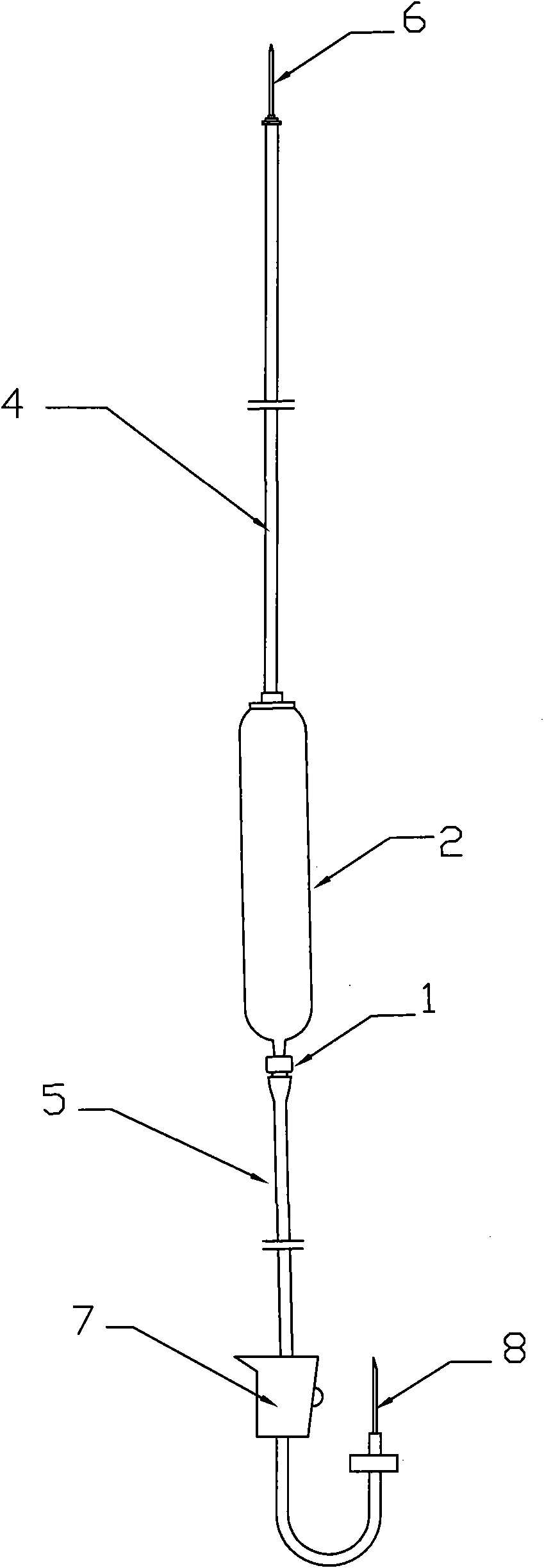

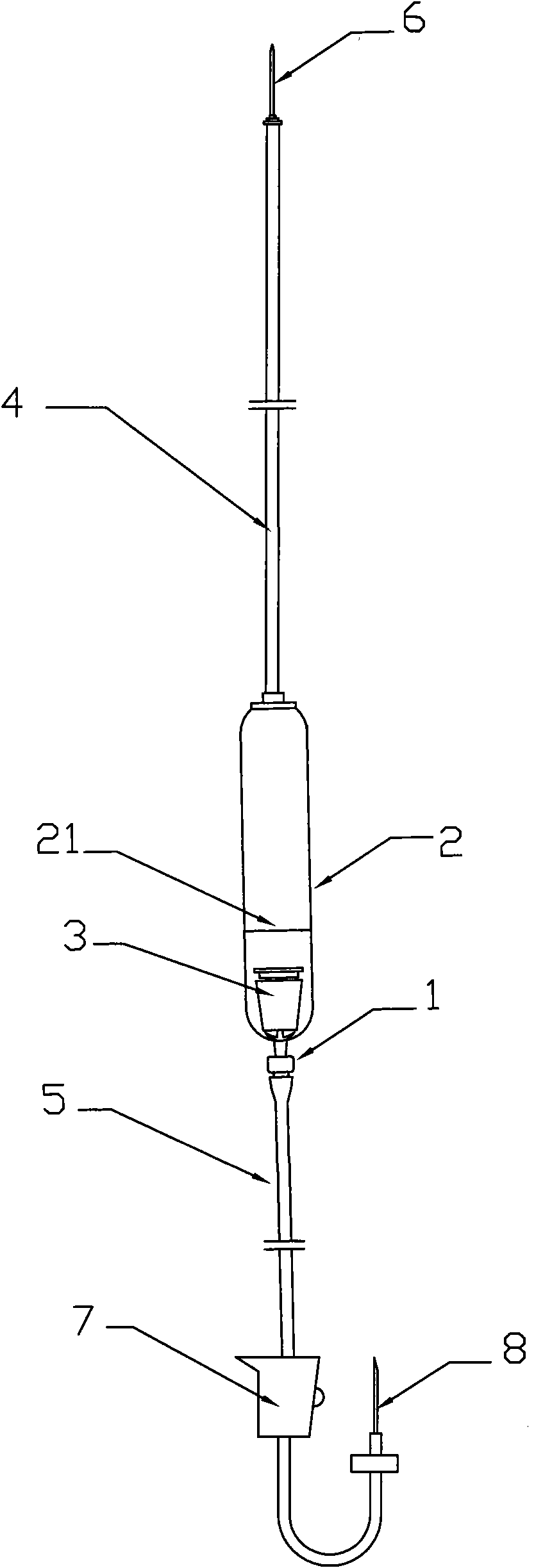

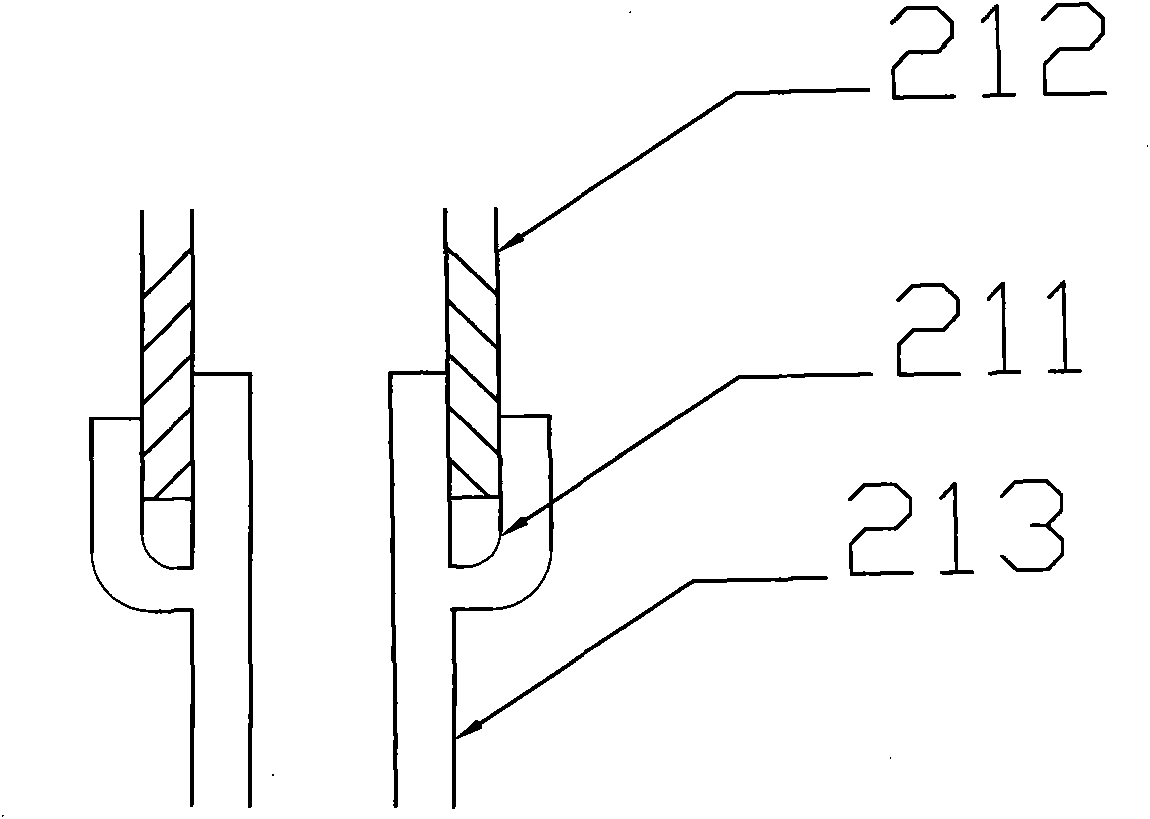

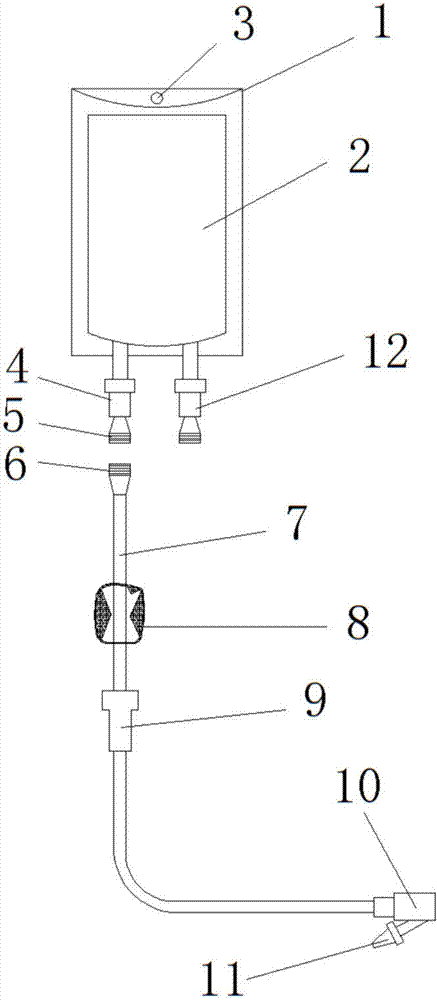

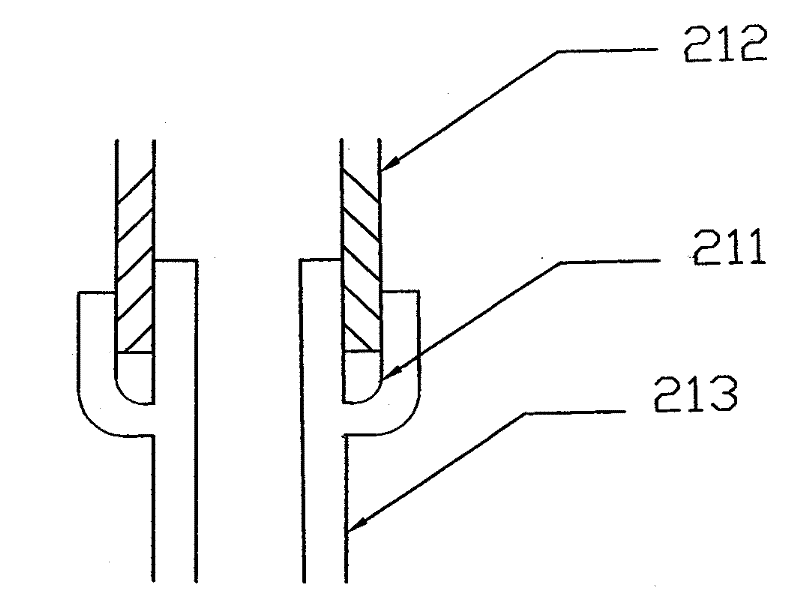

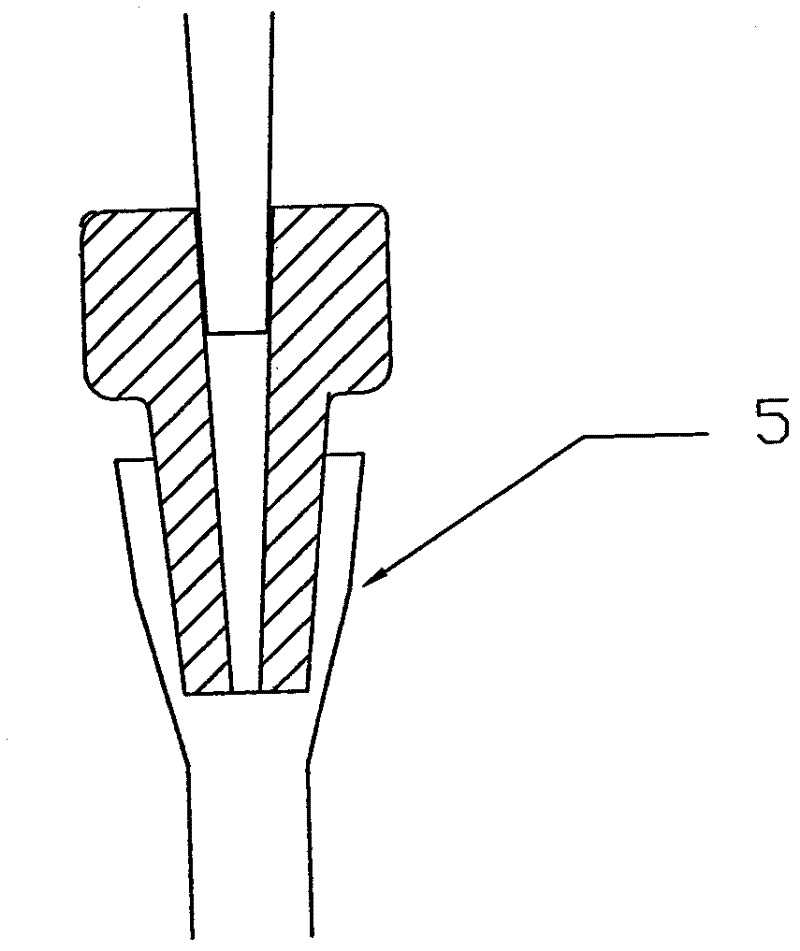

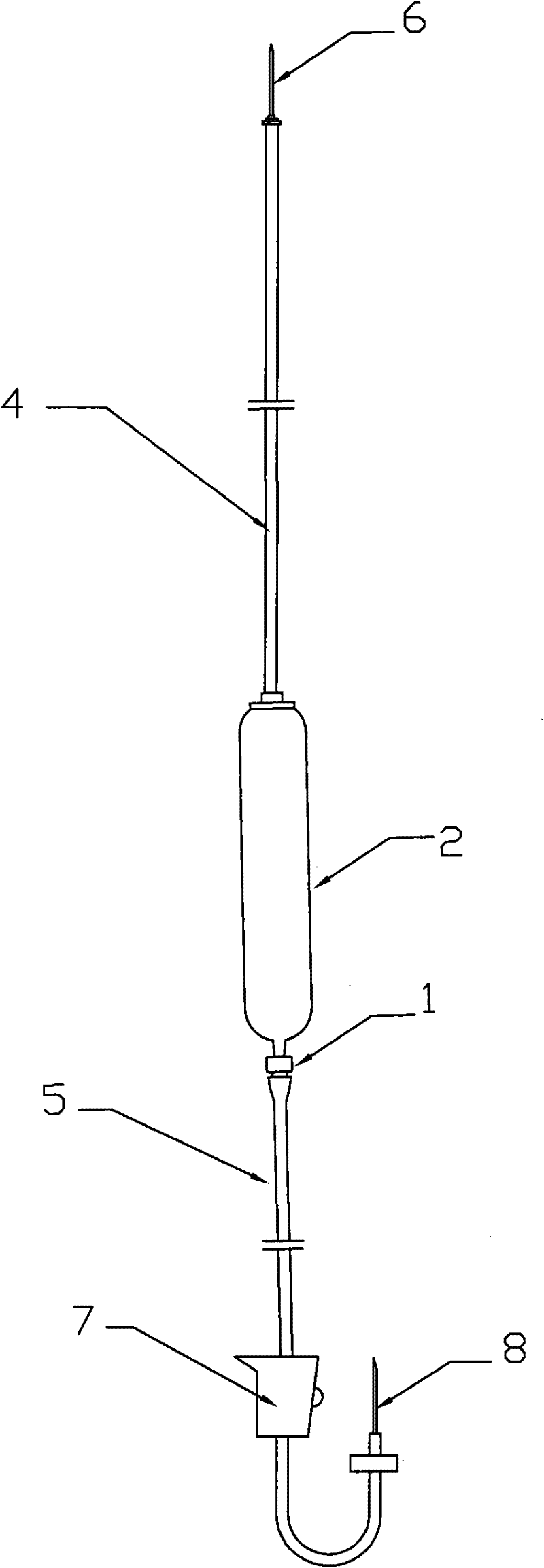

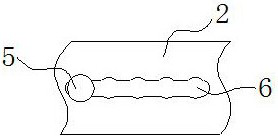

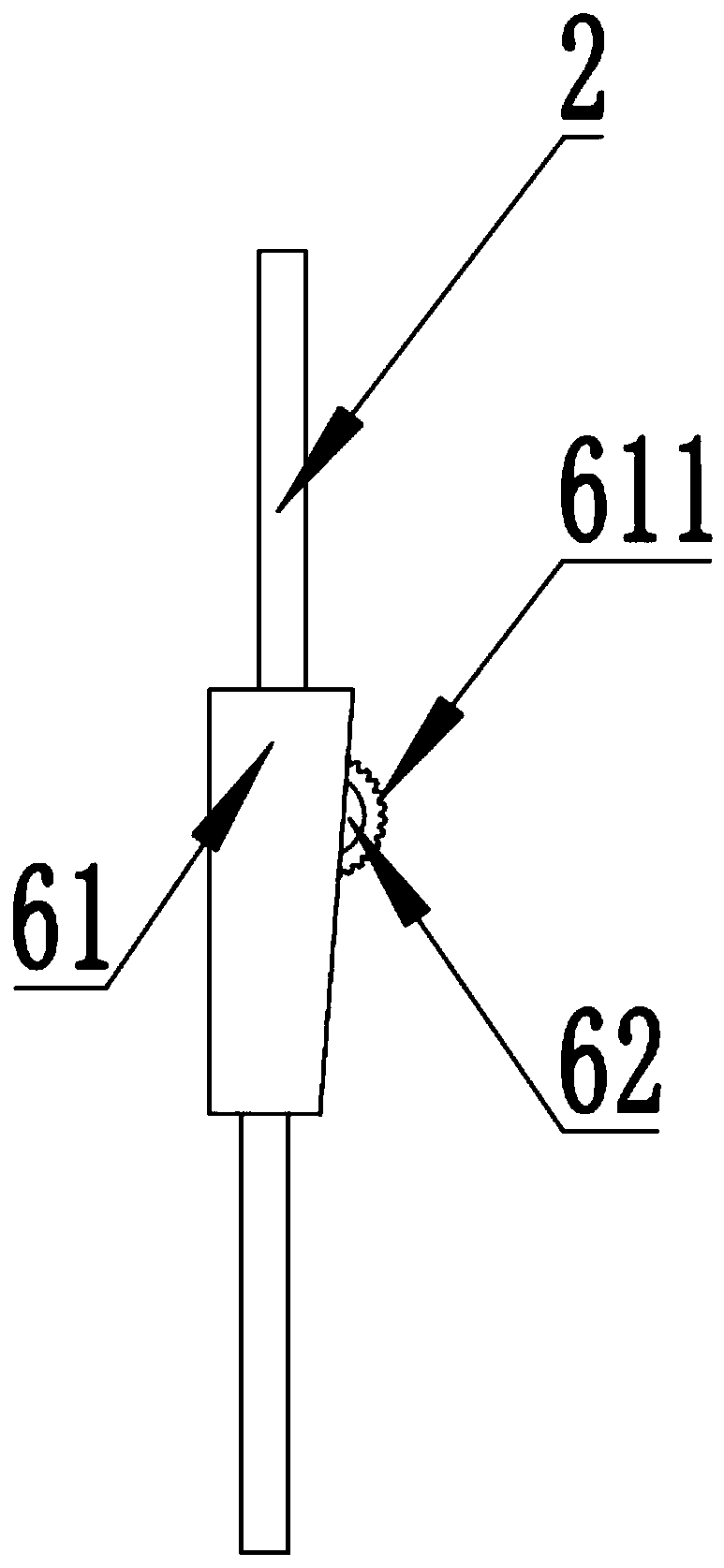

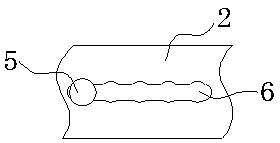

Automatic vent type transfusion set

ActiveCN101879340ATo achieve the purpose of automatic exhaustSimple structureInfusion devicesEngineeringSelf-gravitation

The invention discloses an automatic vent type transfusion set. The automatic vent type transfusion set comprises an upper transfusion pipe, a drop funnel, a lower transfusion pipe, and a regulating switch; a liquid inlet and a liquid outlet of the drop funnel are respectively communicated with a lower end of the upper transfusion pipe and an upper end of the lower transfusion pipe; the regulating switch is arranged on the lower transfusion pipe; a contact pin is connected with an upper end of the upper transfusion pipe; a transfusion needle is connected with a lower end of the lower transfusion pipe; the automatic vent type transfusion set of the invention also comprises a reducer; the reducer is arranged between the liquid outlet of the drop funnel and the lower transfusion pipe; and during transfusion, bubbles entering the reducer are extruded and broken into smaller bubbles at the position of the smallest inner diameter of the reducer, and the smaller bubbles overcome the self-gravitation action to float upwards so as to be discharged, so that the aim of automatically venting gas is fulfilled. The automatic vent type transfusion set has the advantages of simple structure, convenient processing, and capability of achieving effects of venting the gas in real time and smoothly transfusing liquid medicine.

Owner:四川普瑞斯生物科技有限公司

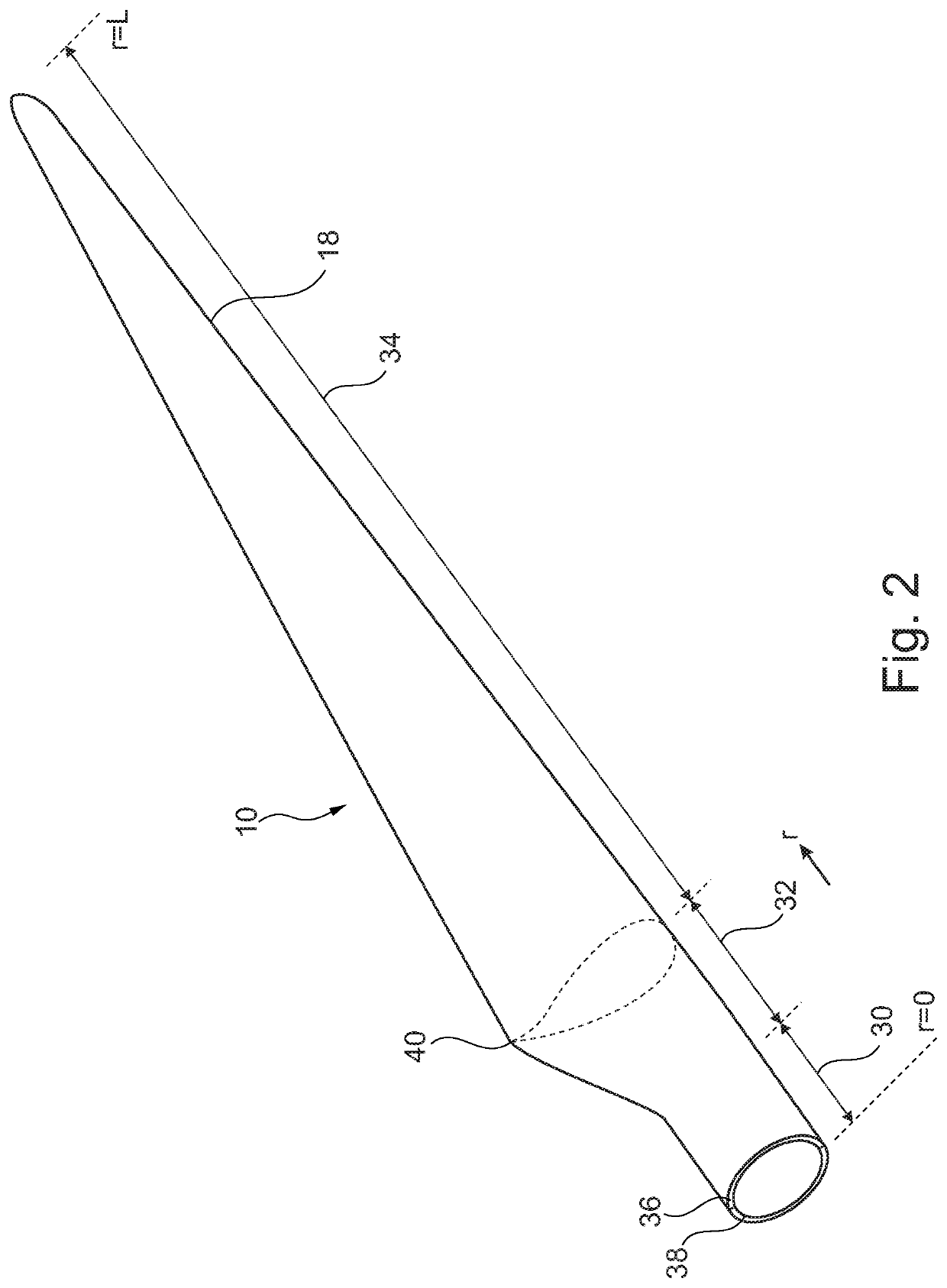

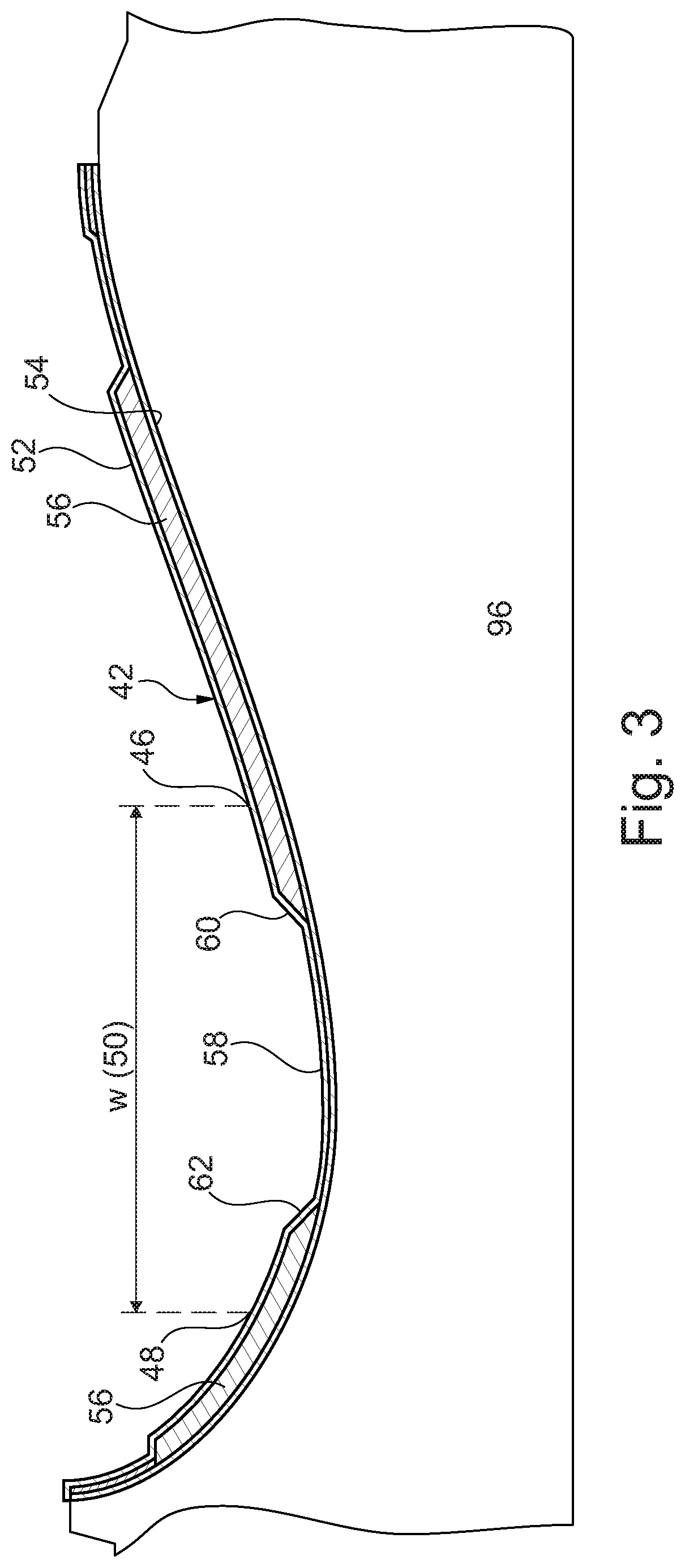

Method of Manufacturing A Wind Turbine Blade

ActiveUS20190176413A1Reduce riskSmoother transitionEngine manufactureFinal product manufactureVacuum assistedTurbine blade

In a method for manufacturing a wind turbine blade half shell, a preformed and cured aerodynamic blade shell member 42 of a fibre reinforced resin is provided. A primarily uniaxial fibre material 66 comprising carbon fibre is laid up on a longitudinal inner area 50 of the preformed shell member 42 and then infused with a resin by vacuum-assisted resin transfer moulding (VARTM), where a longitudinal resin inlet channel 80,82 is arranged on a first lateral side 46 and a vacuum channel 86,88 is arranged on a second lateral side 48 of the laid-up fibre material, and the resin is infused in transverse direction from the first to the second lateral side 46,48.

Owner:LM WP PATENT HLDG

Needle-less infusion instrument

InactiveCN107362409AEasy to addRelieve painInfusion devicesPharmaceutical containersInfusion timeCatheter

The invention discloses a needle-less infusion instrument which comprises a main body and an infusion bag, wherein the infusion bag is arranged at the top of the main body; a suspending hole is formed at the top end of the infusion bag; a first joint is arranged at the bottom of the infusion bag; a second joint is arranged on one side of the first joint; the first joint and the second joint are arranged in parallel; a screw cap is arranged at the bottom of the first joint; a threaded part is arranged at the bottom of the screw cap; the screw cap is in threaded connection with the threaded part; an infusion clip is arranged at the bottom of the threaded part; an infusion instrument is arranged at the bottom of the infusion clip; and the threaded part, the infusion clip and the infusion instrument are connected with each other through catheters. According to the invention, the screw cap and the threaded part are arranged in threaded connection with each other, so that the infusion instrument need not be replaced even if the upper part of the infusion instrument falls off in the infusion process of the patient, the saving of resource and infusion time is benefited, and meanwhile, the infusion clip is arranged, so that the liquid flow rate in the infusion process can be controlled according to the specific condition, the infusion can be stopped at any time if necessary and the increasing of the infusion efficiency is increased.

Owner:芜湖凡达机械科技有限公司

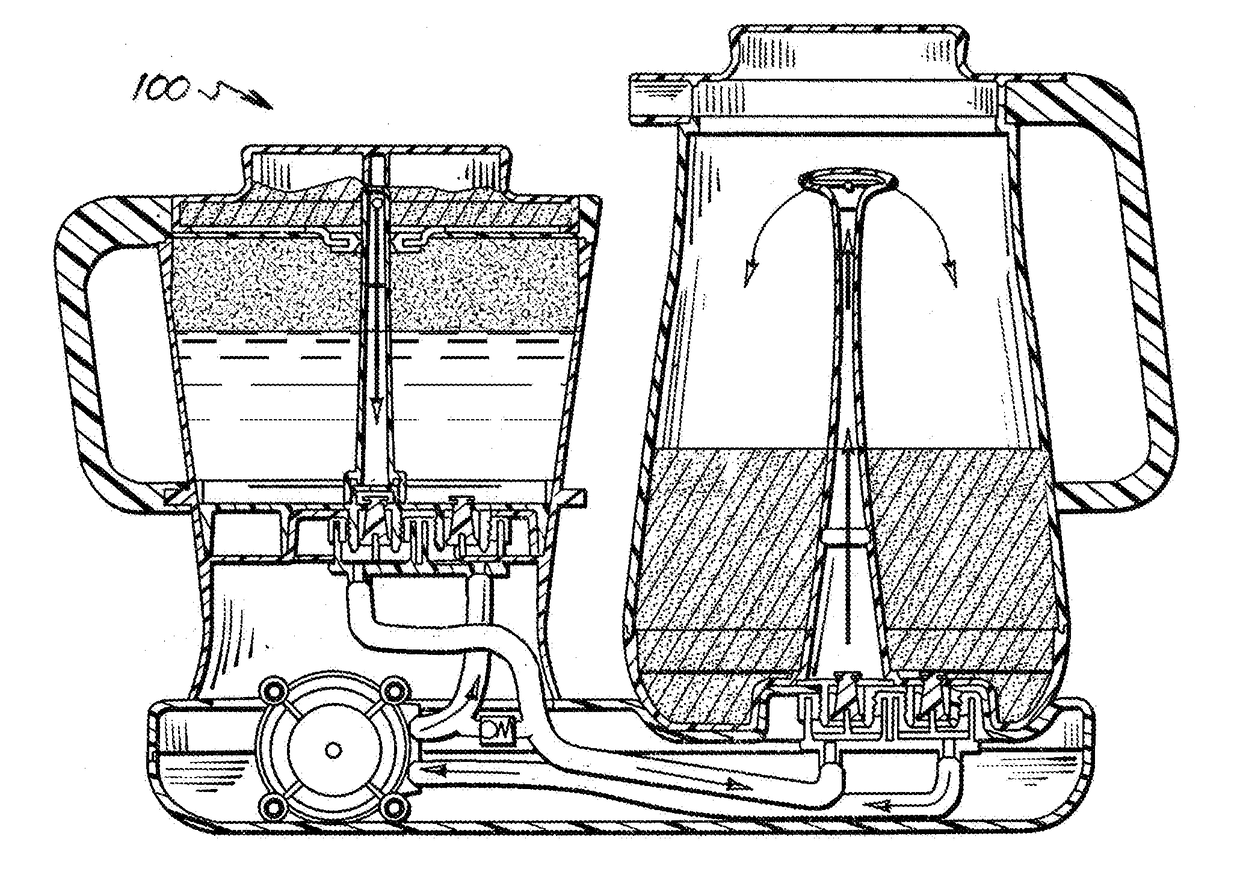

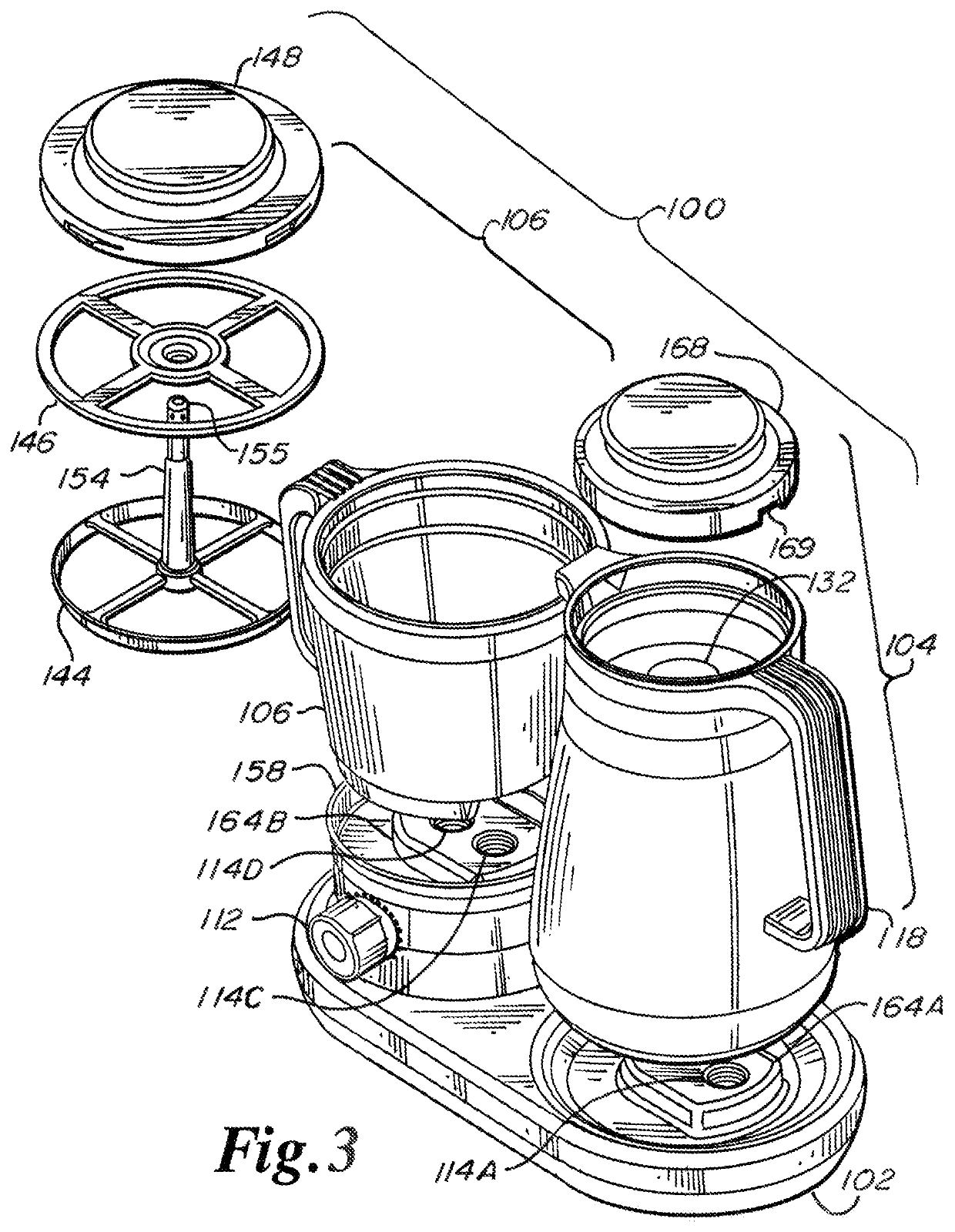

Infusion beverage apparatus

ActiveUS20180110363A1Maximizing extractionShorten infusion timeBeverage vesselsWater circulationEngineering

A cool coffee infusing apparatus is disclosed having a liquid container, a ground coffee container, and a base. The base includes a pump, controls therefore, and receptacles for the containers. The liquid container is filled with cool water and the ground coffee container is filled with ground coffee. The pump circulates the water through the grounds until a desired level of infusion is achieved and coffee beverage is created. The coffee beverage is collected in the liquids container for pouring or for storage for later use.

Owner:APPLIANCE DEVMENT

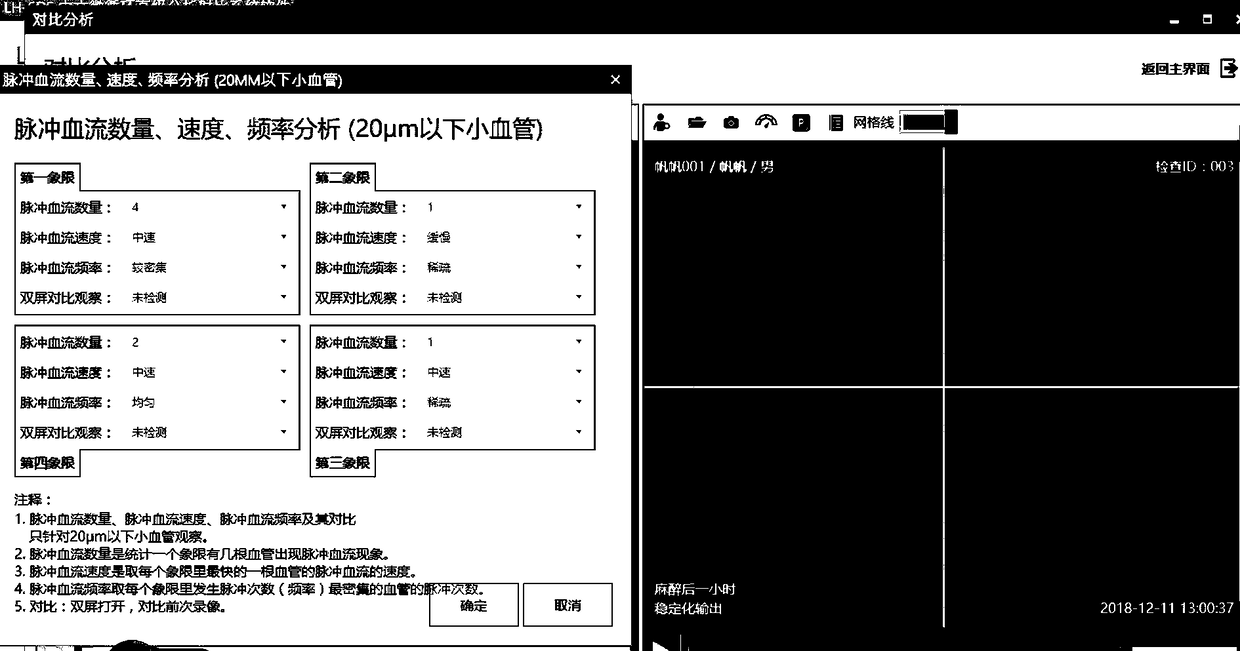

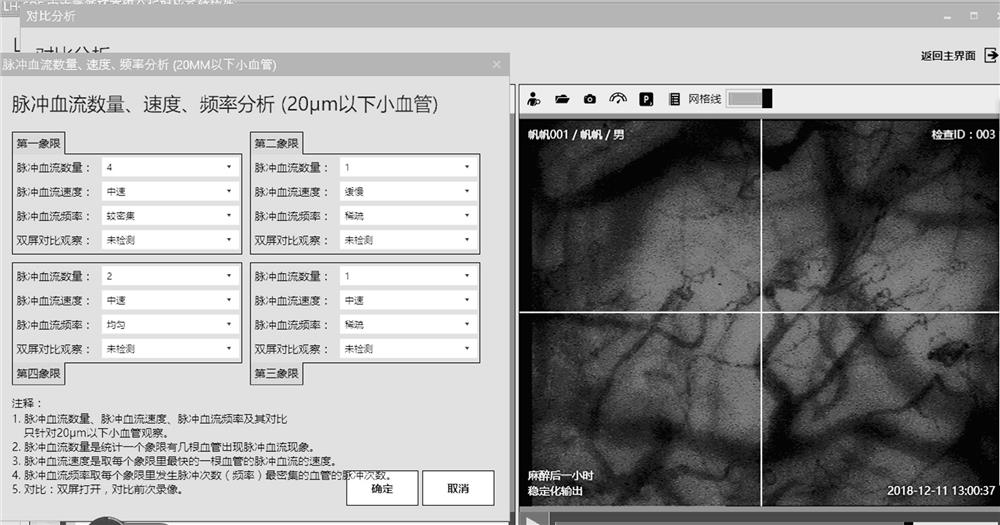

Microcirculation pulse blood flow monitoring system and method used for liquid therapy and capacity management

ActiveCN109394200AAddressing the lack of clinical gold indicatorsReduce the burden onBlood flow measurementPulmonary edemaCapacity management

The invention discloses a microcirculation pulse blood flow monitoring system and method used for liquid therapy and capacity management, and belongs to the technical field of medical treatment monitoring. The monitoring system comprises a data collecting module, a storage module and a comparison module. At different times, repeated positioning is conducted on blood capillaries in the same monitored region, and blood vessel image data is collected and stored; the measurement data of blood vessel images collected at different times are compared, the number of blood vessels where pulse blood flow occurs and / or the speed of pulse blood flow and / or the frequency of pulse blood flow occurrence are used as indexes for making capacity management and liquid therapy accurate, and the problem is solved that liquid therapy and capacity management lack clinical golden indexes. Through the monitoring system, a heart failure, pulmonary edema and tissue edema of lungs caused by excessive transfusionare avoided, the burden of kidneys is reduced, transfusion time is shortened, treatment costs are lowered, and the pains of patients are relieved.

Owner:冯兴怀

Method of manufacturing a composite laminate structure

ActiveUS10723090B2Provide usageRisk minimizationEngine manufactureSynthetic resin layered productsPolymer scienceCarbon fibers

Owner:LM WP PATENT HLDG

Automatic vent type transfusion set

ActiveCN101879340BTo achieve the purpose of automatic exhaustSimple structureInfusion devicesSelf-gravitationEngineering

The invention discloses an automatic vent type transfusion set. The automatic vent type transfusion set comprises an upper transfusion pipe, a drop funnel, a lower transfusion pipe, and a regulating switch; a liquid inlet and a liquid outlet of the drop funnel are respectively communicated with a lower end of the upper transfusion pipe and an upper end of the lower transfusion pipe; the regulating switch is arranged on the lower transfusion pipe; a contact pin is connected with an upper end of the upper transfusion pipe; a transfusion needle is connected with a lower end of the lower transfusion pipe; the automatic vent type transfusion set of the invention also comprises a reducer; the reducer is arranged between the liquid outlet of the drop funnel and the lower transfusion pipe; and during transfusion, bubbles entering the reducer are extruded and broken into smaller bubbles at the position of the smallest inner diameter of the reducer, and the smaller bubbles overcome the self-gravitation action to float upwards so as to be discharged, so that the aim of automatically venting gas is fulfilled. The automatic vent type transfusion set has the advantages of simple structure, convenient processing, and capability of achieving effects of venting the gas in real time and smoothly transfusing liquid medicine.

Owner:四川普瑞斯生物科技有限公司

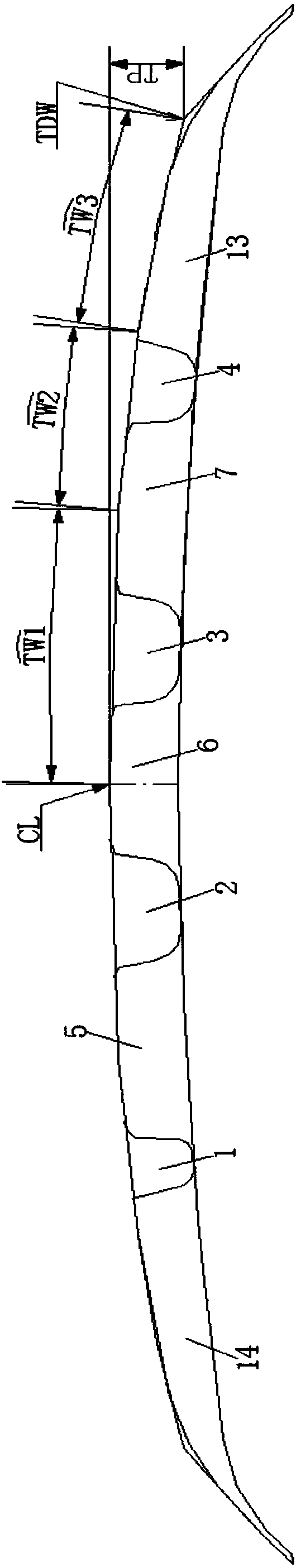

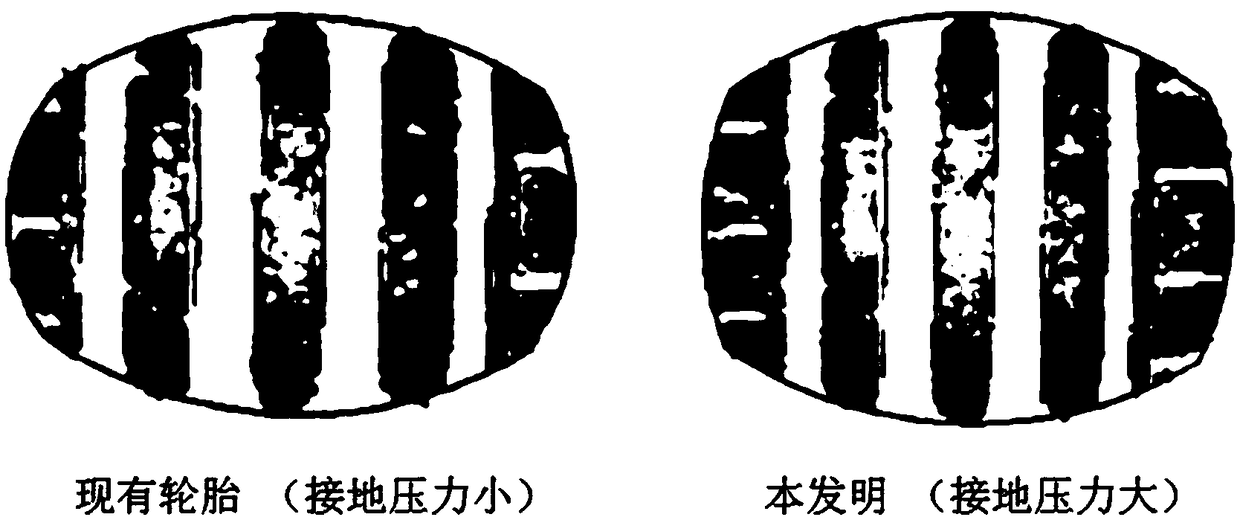

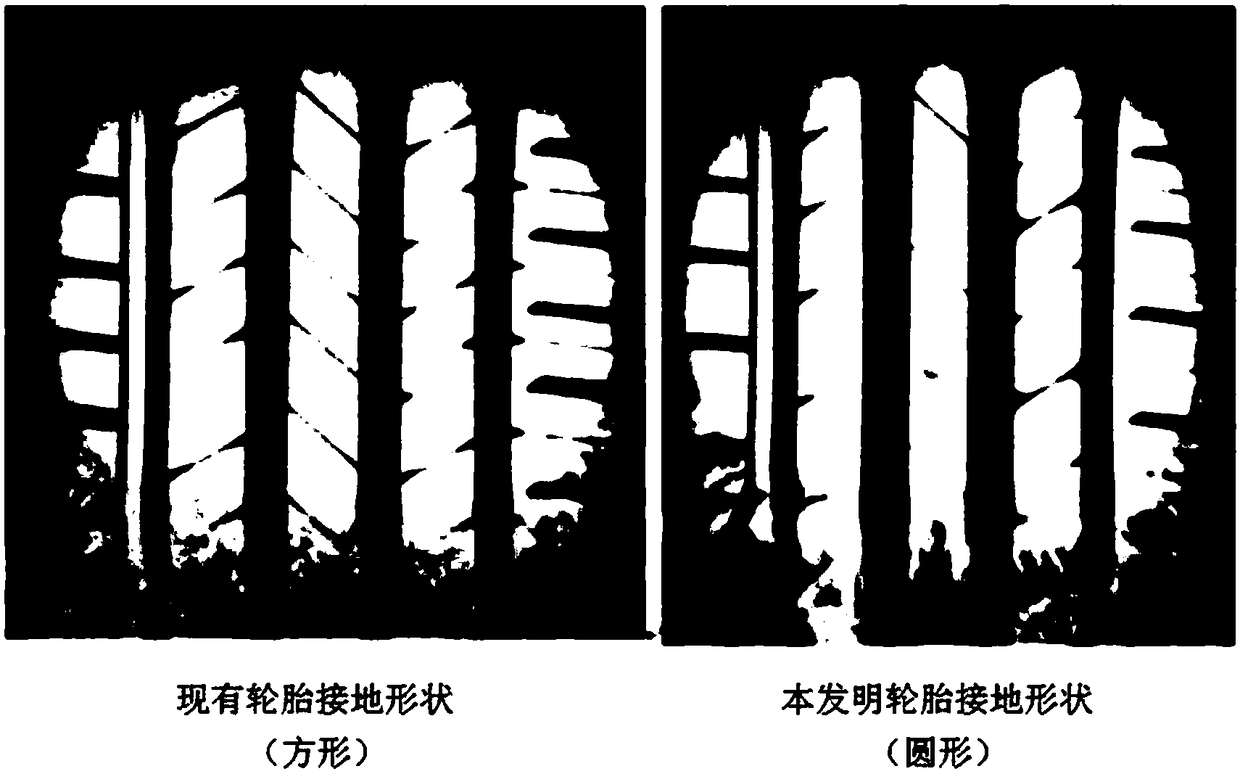

UHP tire for improving wetland performance

InactiveCN108501622AMake up for concave defectsImprove water breaking abilityTyre tread bands/patternsHeight differenceEngineering

The invention discloses a UHP tire for improving wetland performance. The UHP tire for improving wetland performance comprises a tread with the total length of a crown arc being TDW. Longitudinal maingrooves extending in the circumferential direction of the tire are formed in the tread, and pattern blocks extending in the circumferential direction of the tire are formed between the longitudinal main grooves. The relationship that TDW / SN is greater or equal to 0.80 and less than or equal to 0.82 exists between the total length TDW of the crown arc and the nominal section width SN of the tire,and the relationship that TP / TDW is greater than or equal to 0.047 and less than or equal to 0.049 exists between the total length TDW of the crown arc and the height difference TP between center point of the crown arc and the end point of the crown arc. Each pattern block is designed with a thickened convex surface, so that the grounding edges of the pattern blocks present a convex state, and thedefect of the concave faces of grounding edges of the pattern blocks caused by the contraction of the tire compound is overcome; and at the same time, the grounding edges with convex surfaces improvethe water breaking capacity of the tire, effectively avoid the water slip during wheel driving, and improve the use safety and stability of the tire.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

Infusion beverage apparatus

ActiveUS10980369B2Maximizing extractionShorten infusion timeBeverage vesselsProcess engineeringGround coffee

A cool coffee infusing apparatus is disclosed having a liquid container, a ground coffee container, and a base. The base includes a pump, controls therefore, and receptacles for the containers. The liquid container is filled with cool water and the ground coffee container is filled with ground coffee. The pump circulates the water through the grounds until a desired level of infusion is achieved and coffee beverage is created. The coffee beverage is collected in the liquids container for pouring or for storage for later use.

Owner:APPLIANCE DEVMENT

Mould tool for manufacture of a wind turbine blade

PendingUS20220134685A1Reduced space requirementsSingle infusionFinal product manufactureDomestic articlesTurbine bladeEngineering

Disclosed is a mould tool for manufacturing a plurality of pre-form laminates for a laminate of a wind turbine blade, the mould tool comprising a frame, a first mould surface configured for receiving a first fabric, a second mould surface configured for receiving a second fabric, and a heating arrangement configured to heat the first mould surface and the second mould surface. The mould tool is configured to turn between a first configuration and a second configuration, wherein in the first configuration the first mould surface is facing substantially upwards, and in the second configuration the second mould surface is facing substantially upwards.

Owner:LM WINDPOWER +1

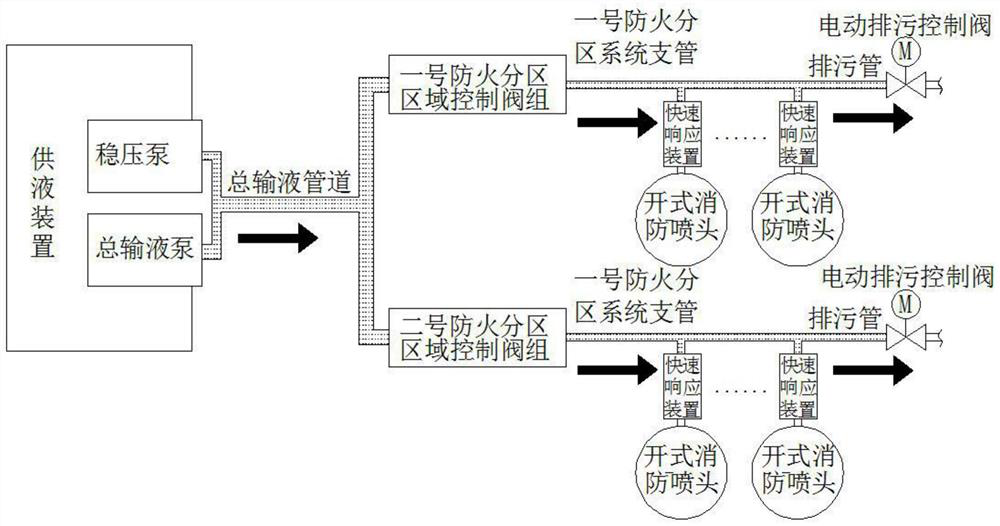

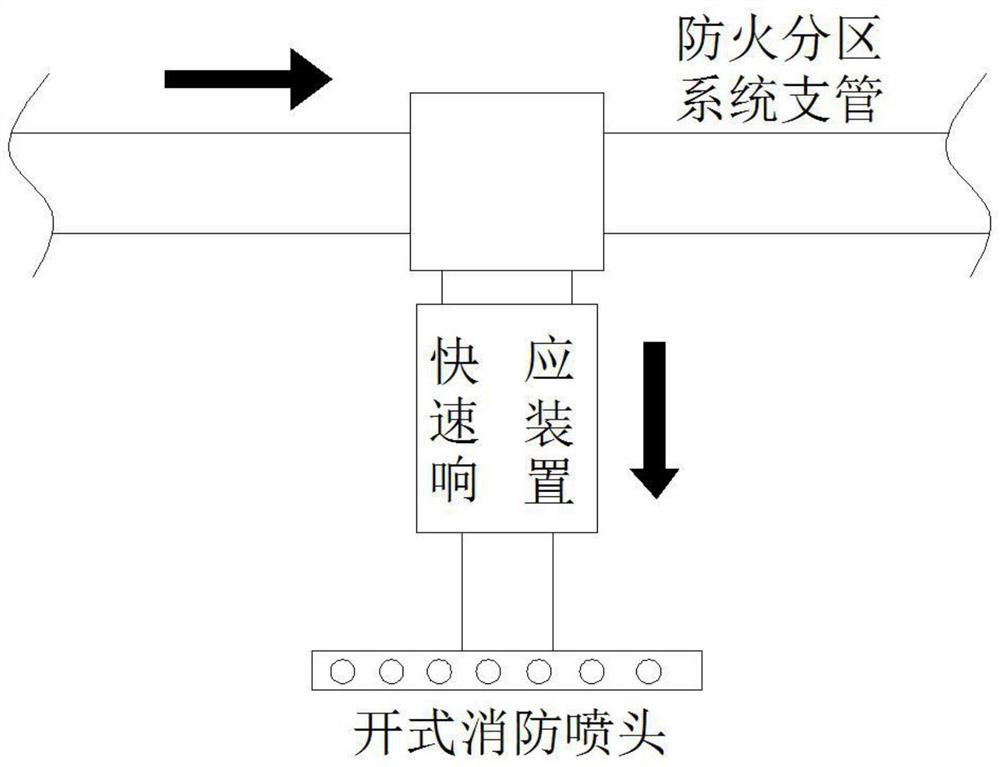

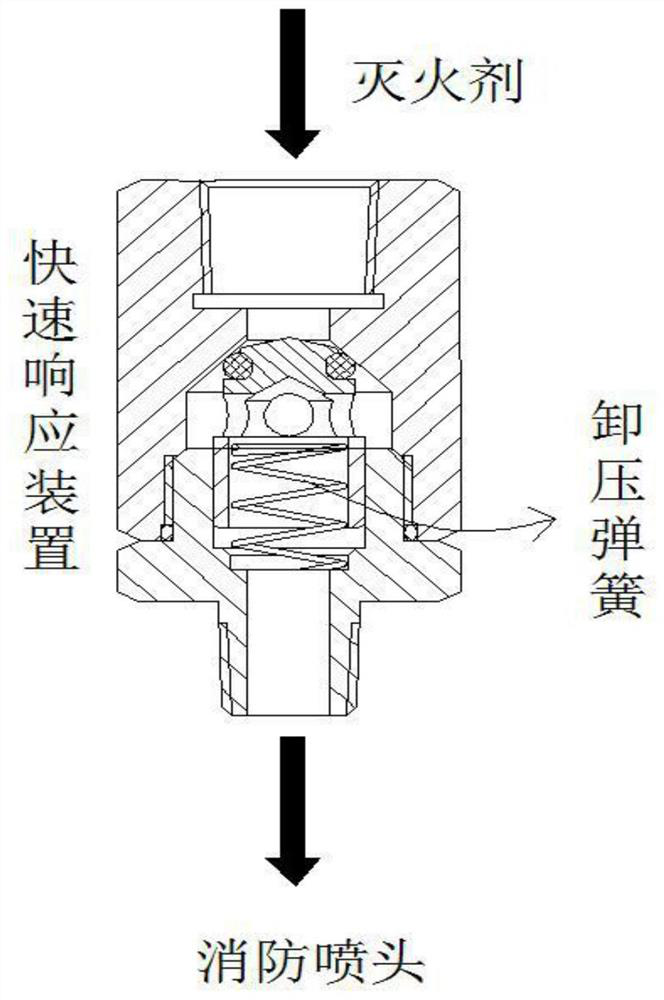

Method for prolonging response time of open fire extinguishing system

PendingCN114073834AShorten infusion timeReduce waiting time for infusionFire rescueOpen fireEnvironmental geology

The invention discloses a method for prolonging the response time of an open fire extinguishing system. The method comprises the following steps that: step 1, a fire-fighting pipeline framework is sequentially provided with a liquid supply device, a main liquid conveying pipeline, area control valve groups, system branch pipes and fire-fighting sprayers, wherein the liquid supply device comprises a main liquid conveying pump connected with the main liquid conveying pipeline, the main liquid conveying pipeline is connected with a plurality of the area control valve groups, each area control valve group corresponds to different fire zones, and the area control valve groups are connected with the system branch pipes mounted in the fire zones; and step 2, the system branch pipes are connected with a certain number of the fire-fighting sprayers to meet the fire-fighting protection requirements of the fire zones, and a special quick response device is arranged between each fire-fighting sprayer and the corresponding system branch pipe. In an open type fire extinguishing system with the large space of a single fire compartment or the long span of the single fire compartment, the response time of the fire extinguishing system can be prolonged in the mode that the system branch pipes are filled with a fire extinguishing agent for a long time, and more losses caused by fire behavior increase are prevented.

Owner:WUHU SHIJI KAIXUAN FIRE EQUIP

Method of manufacturing a wind turbine blade

ActiveUS10946598B2Inhibition formationShorten infusion timeEngine manufactureFinal product manufactureFiberCarbon fibers

Owner:LM WP PATENT HLDG

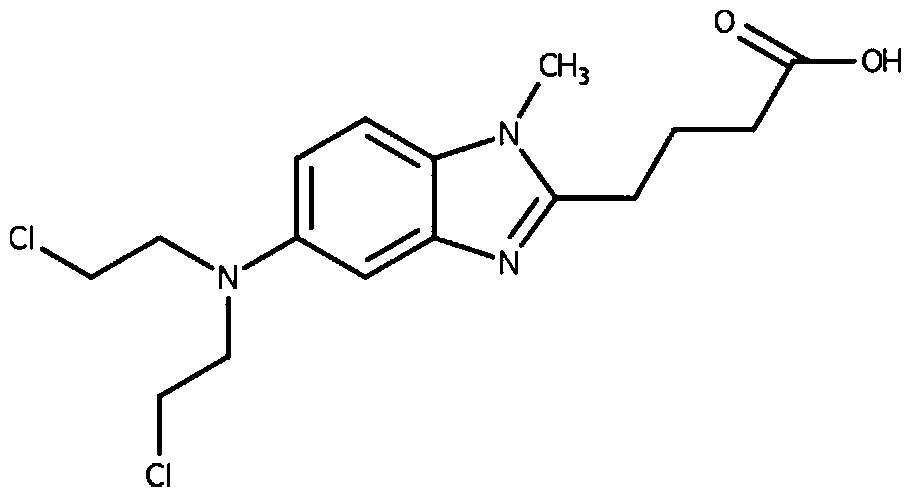

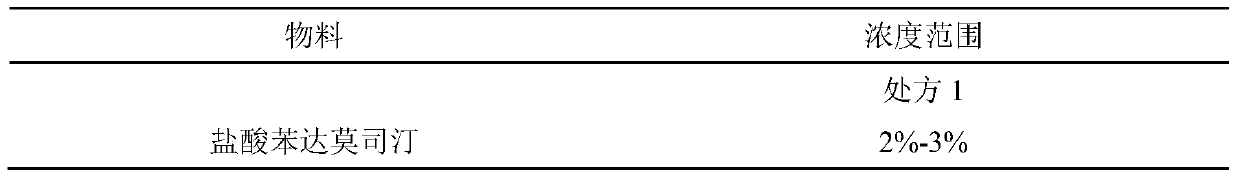

Medicinal composition and application of bendamustine

ActiveCN105726472BReduce the volume of injectionImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismDrugs solutionBendamustine hydrochloride

The invention discloses a bendamustine pharmaceutical composition comprising: 1.5%-5% bendamustine or a pharmaceutically acceptable salt or ester or solvate thereof, 0%-20% stabilizer, 0.05%-2 % antioxidant, 0%‑0.008% pH regulator, and the rest exclusive solvent. In clinical use, according to the dosage of the patient, 10-100mL injection can be used to dilute the bendamustine hydrochloride with a final concentration of 0.1mg / mL-10mg / mL for use, and the preliminary stability test shows that the present invention can be used after dilution At 25°C or 5°C, it is stable for 48 hours. Compared with commercially available lyophilized preparations, the volume of diluent used is reduced (the existing lyophilized preparations require 500mL injection to be reconstituted), and the stability of the diluted drug solution Improvement, patient compliance is good, and existing clinical problems are solved.

Owner:NANJING BAIXINYU PHARM CO LTD

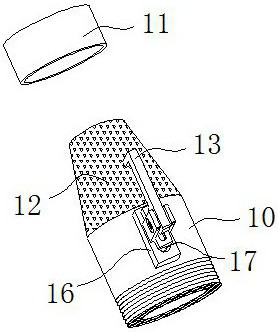

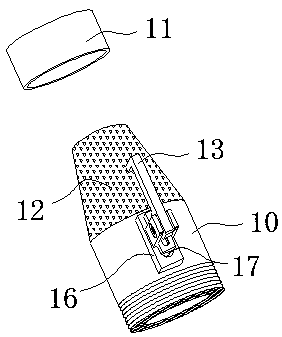

A replaceable infusion device

ActiveCN108969833BFlexible switchingReduce caregiver stressInfusion devicesFlow controlIntensive care medicineFluid administration

The invention discloses a replaceable infusion device, comprising an infusion tube, the infusion tube is connected with a regulating box whose center is a regulating cavity, the upper end surface of the regulating box is provided with two liquid inlet holes, and the bottom surface of the regulating box is provided with two liquid inlet holes. Correspondingly, there are two liquid outlet holes, a regulating valve is built in the regulating chamber, and two infusion through holes are arranged on the regulating valve, and the infusion liquid is passed between each infusion hole and its corresponding infusion hole. The through holes communicate with each other, an adjustment handle is arranged in the center of the adjustment valve, and an adjustment groove is arranged on the adjustment box. the infusion tube. The replaceable infusion device of the present invention can flexibly and quickly replace different infusion tubes, save time and manpower, and reduce the risk of infusion.

Owner:苏州市百世康医疗器械有限公司

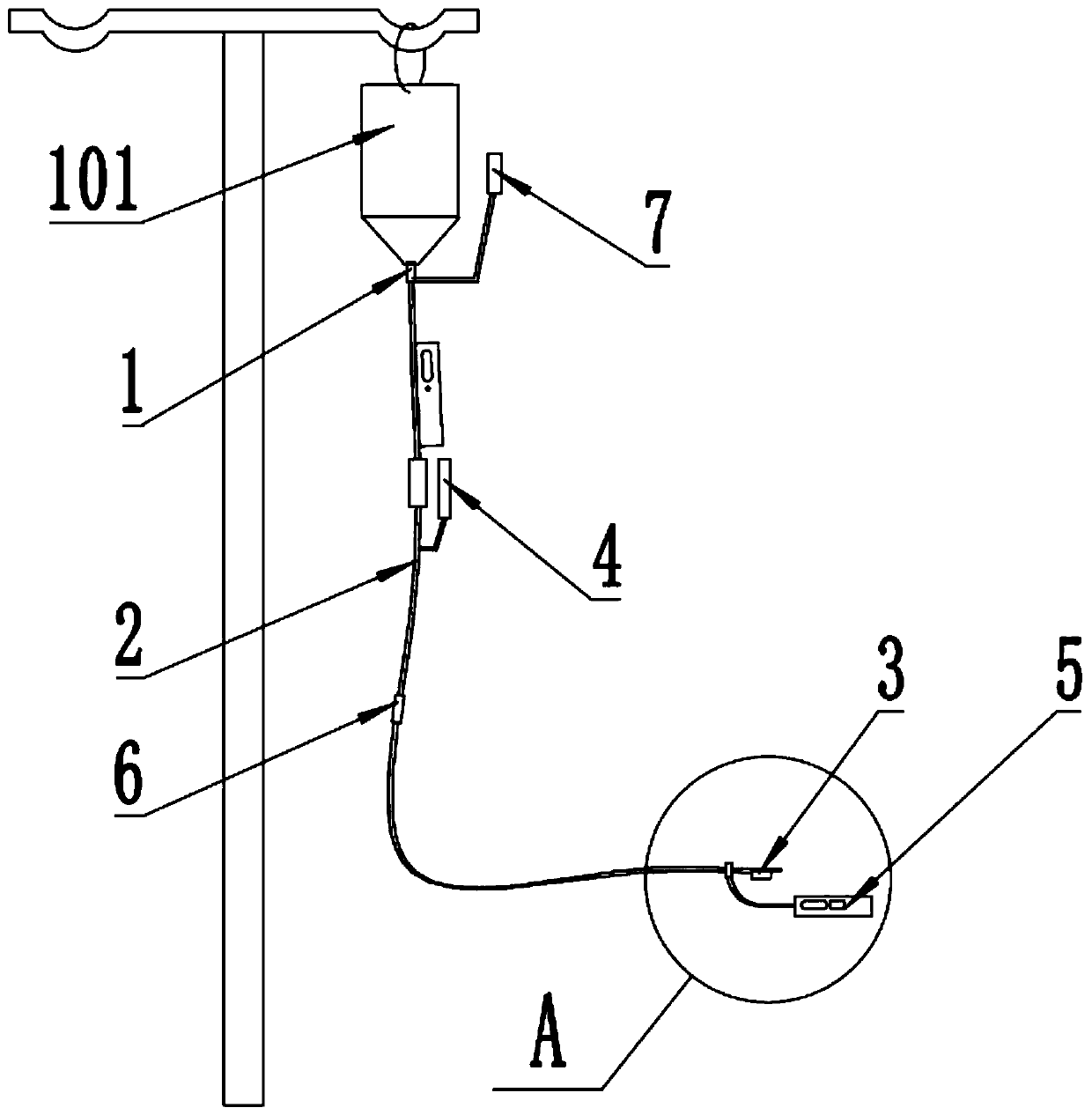

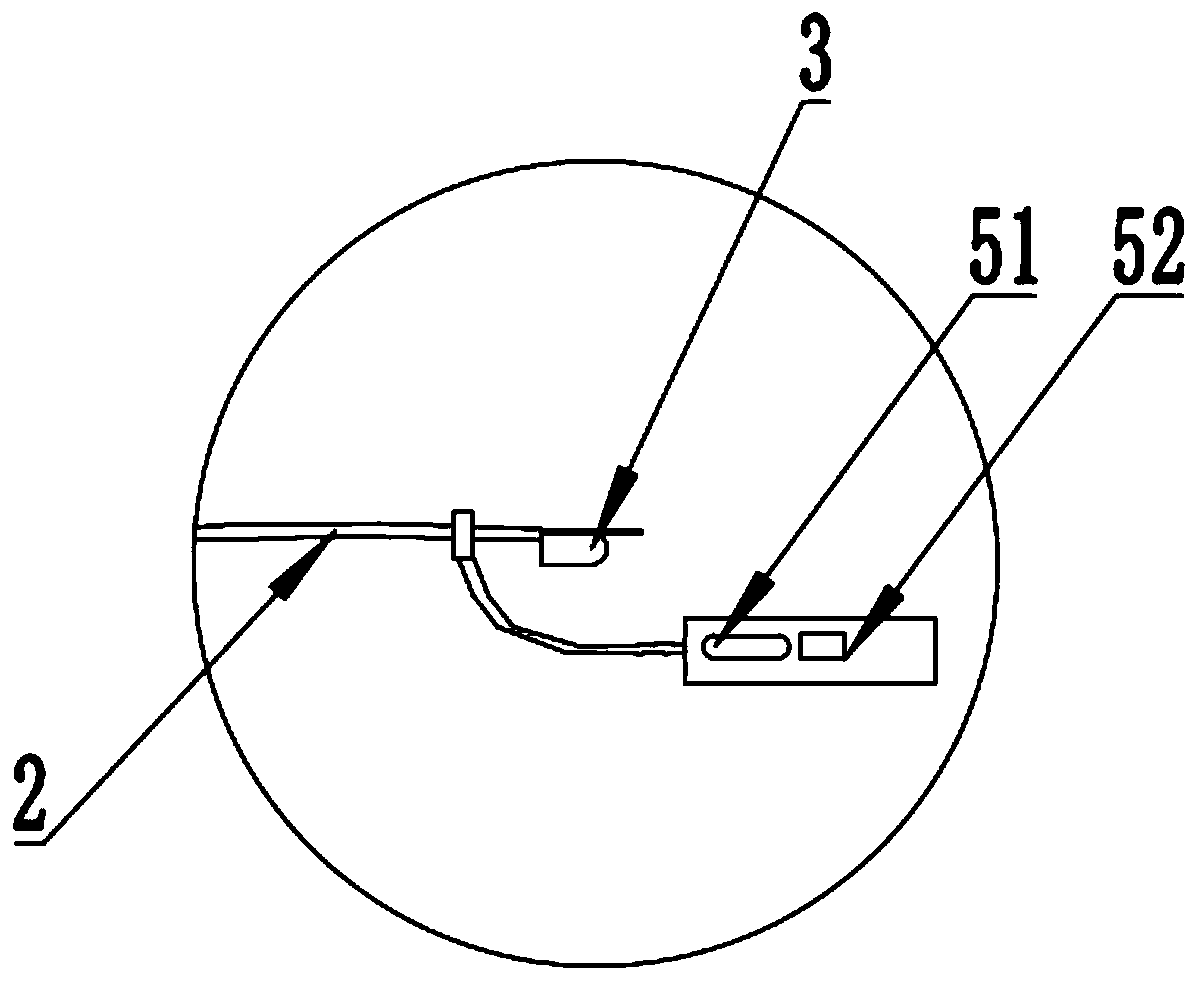

Infusion device

InactiveCN111282086AShorten infusion timeShorten the timeElectrocardiographyMedical devicesCardiologyHeart rate monitoring

The invention discloses an infusion device. A heart rate monitoring mechanism and an infusion speed control mechanism are arranged; the heart rate of the patient is monitored; when the patient heart rate is stable, the infusion speed is properly increased, namely the flow rate is the infusion flow rate in the infusion hose; infusion time is shortened, time is saved for patients, the utilization ofhospital resources is improved, when the heart rate of the patient is too high; the infusion speed is properly reduced, discomfort of the patient in the infusion process is reduced; the security is enhanced, a setting mechanism, a flow velocity measuring mechanism and an infusion speed control mechanism are arranged; a transfusion flow speed interval can be set; for example, different flow rate intervals can be set for different kinds of medicine, when the infusion speed reaches the boundary of the flow rate intervals, the infusion speed adjusting mechanism is stopped, and due to the fact that measurement data is abnormal or other reasons exist, the adjusted infusion speed exceeds the normal range, and damage is caused to the body health of the patient.

Owner:利辛县儒康医药有限公司

External use analgesic cream for transfusion

InactiveCN1682708ASimple preparation processReduce manufacturing costOrganic active ingredientsAntipyreticIrritationAllergy

The present invention discloses a kind of externally applied analgesic cream for transfusion, and belongs to the field of externally applied medicine technology. The present invention contains tetracaine hydrochloride in 1-5 wt% and cream medium the rest. The present invention is used in relieving pain of the transfusion part, may be used clinically to shorten the transfusion time, and has the features of low cost, long pain relieving time, no irritation, no allergy, etc.

Owner:沈美华 +1

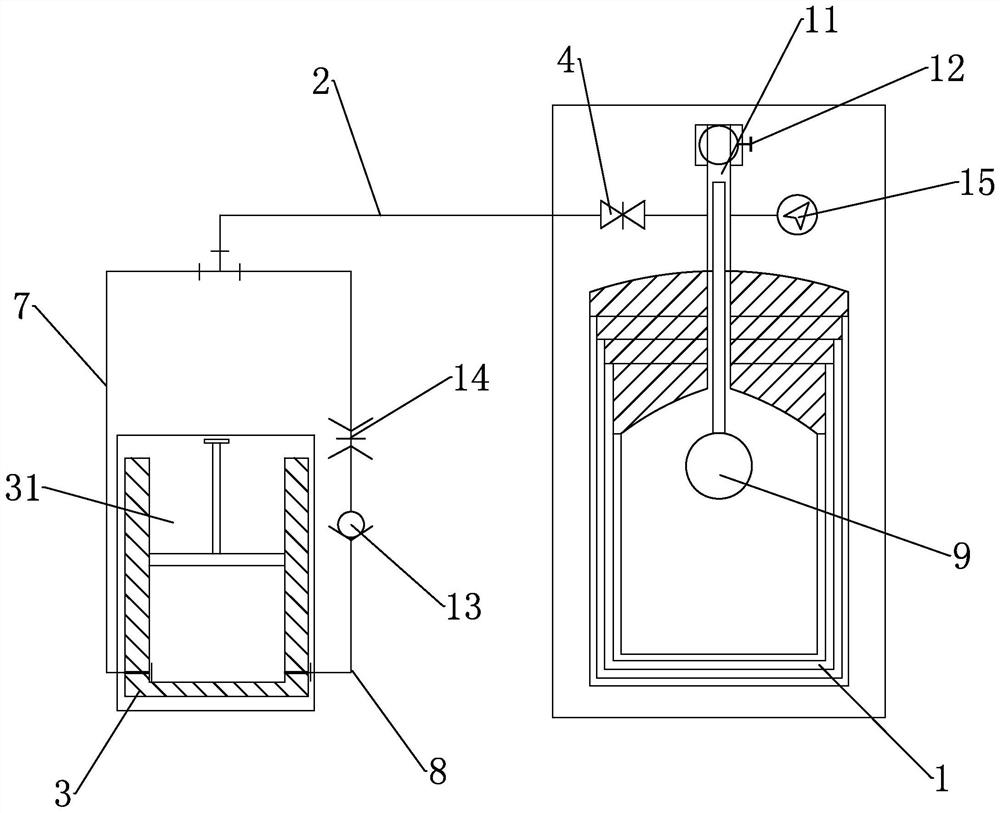

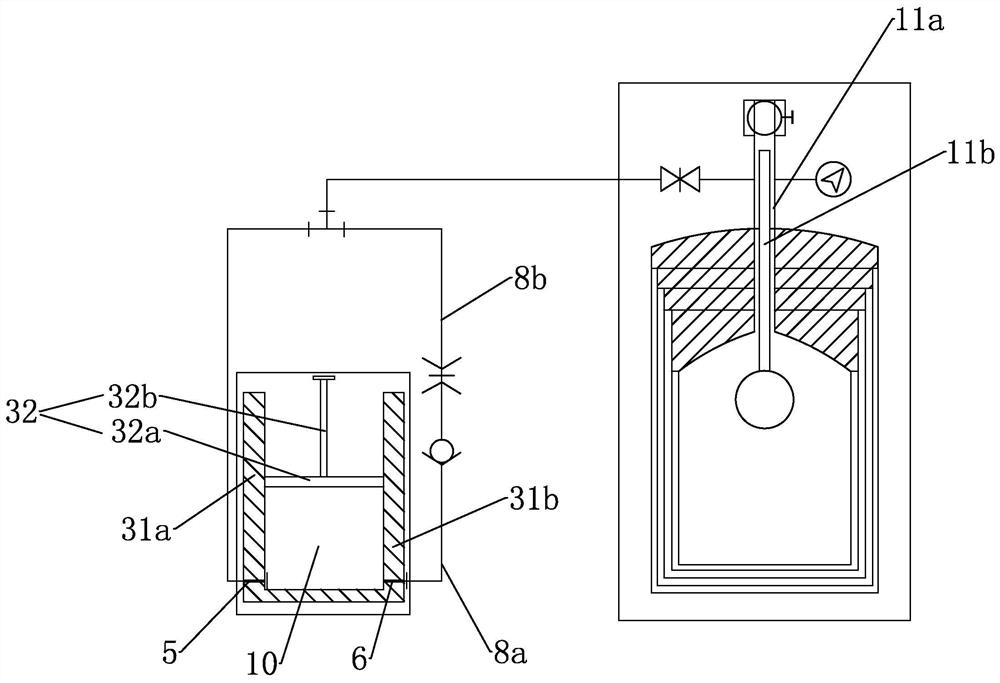

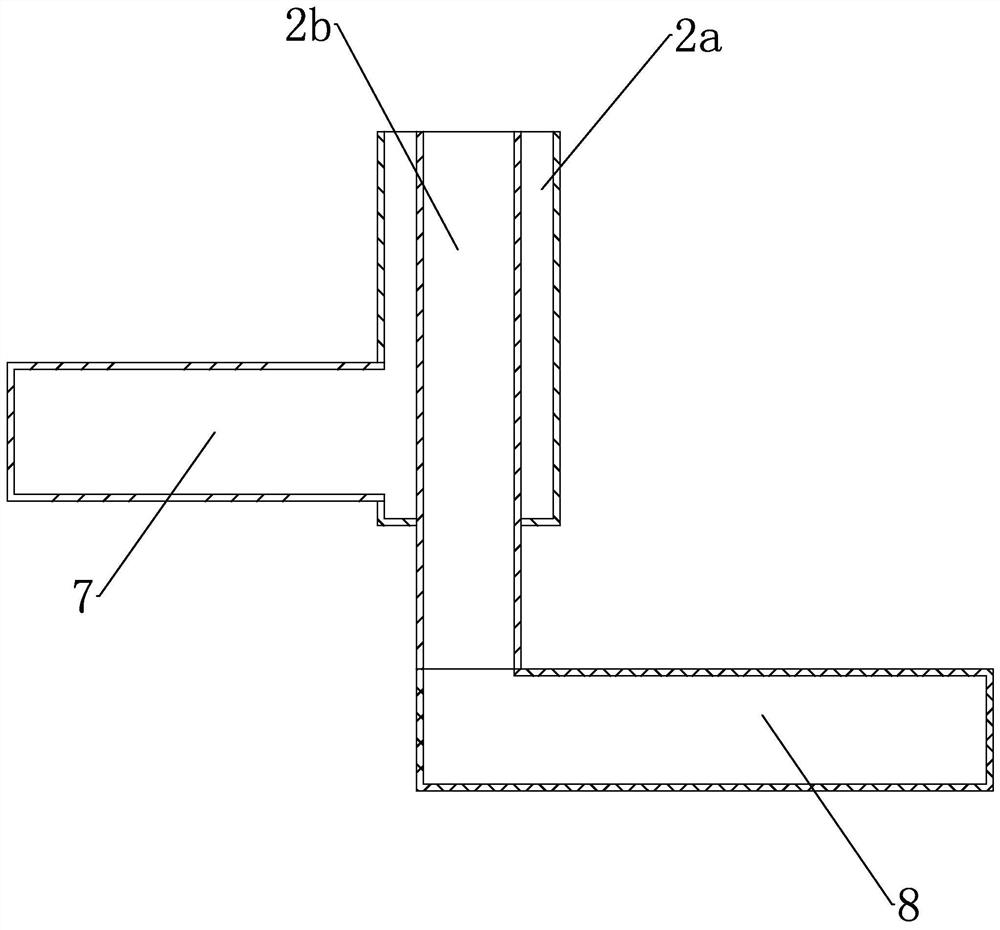

A self-pressurization device and pressurization method for liquid helium Dewar

ActiveCN111622925BAchieve emissionsReduce usagePositive displacement pump componentsContainer filling methodsExhaust valveEngineering

A self-pressurizing device and a pressurizing method for a liquid helium dewar, aiming at solving the technical problems in the prior art that the liquid helium dewar pressurization method easily causes waste of helium and the cost of the pressurization operation is high. The invention includes a Dewar for storing low-temperature liquefied gas. The Dewar communicates with an external heat exchange piston through a first pipeline. The first pipeline is provided with a booster valve. The heat exchange piston includes a heat exchange chamber and can The reciprocating sliding piston rod in the heat chamber, the first pipe includes an outer pipe and an inner pipe, the gas flows in the outer pipe and the inner pipe are independent of each other, the heat exchange chamber includes a first side wall and a second side wall, the first side The inlet valve is arranged on the wall, and the exhaust valve is arranged on the second side wall. The inlet valve is connected with the end of the outer pipe away from Dewar through the second pipeline, and the exhaust valve is connected with the end of the inner pipe away from Dewar through the third pipe. The pipes are connected, and the other end of the inner pipe is connected with the heat exchange air bag inside the Dewar.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Microcirculation pulse flow monitoring system and method for fluid therapy, volume management

ActiveCN109394200BAddressing the lack of clinical gold indicatorsReduce the burden onBlood flow measurementInfusion timeBlood flow

The invention discloses a microcirculation pulse blood flow monitoring system and method for fluid therapy and volume management, belonging to the technical field of medical monitoring. The monitoring system of the present invention includes: a data acquisition module, a storage module and a comparison module. The present invention repeatedly locates capillaries in the same monitoring area at different times, collects and stores blood vessel image data; compares the measurement data of blood vessel images collected at different times, and uses the number of blood vessels that generate pulsed blood flow and / or the speed of pulsed blood flow And / or the frequency of pulse blood flow, etc., are used as indicators for accurate volume management and fluid therapy, which solves the problem of lack of clinical gold indicators for fluid therapy and volume management. The invention avoids heart failure, pulmonary edema and tissue edema caused by excessive infusion, reduces the burden on the kidneys, reduces infusion time, treatment cost and patient pain.

Owner:冯兴怀

Self-pressurizing device for liquid helium dewar and pressurizing method

ActiveCN111622925AAchieve emissionsReduce usagePositive displacement pump componentsContainer filling methodsExhaust valveInlet valve

The invention discloses a self-pressurizing device for liquid helium dewar and a pressurizing method, and aims at solving the technical problems that according to a liquid helium dewar pressurizing manner in the prior art, helium waste is likely to be caused, and the pressurizing operation cost is high. The self-pressurizing device comprises the dewar for storing low-temperature liquefied gas. Thedewar communicates with an external heat exchange piston through a first pipeline. The first pipeline is provided with a pressurizing valve. The heat exchange piston comprises a heat exchange cavityand a piston rod capable of sliding in the heat exchange cavity in a reciprocating manner. The first pipeline comprises an outer pipe and an inner pipe. Gas flow in the outer pipe and the inner pipe is independent. The heat exchange cavity comprises a first side wall and a second side wall. The first side wall is provided with an air inlet valve. The second side wall is provided with an exhaust valve. The air inlet valve is connected with the end, away from the dewar, of the outer pipe through a second pipeline. The exhaust valve is connected with the end, away from the dewar, of the inner pipe through a third pipeline, and the other end of the inner pipe is connected with a heat exchange air bag arranged in the dewar.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Parenteral Nutrition Infusion Pump

ActiveCN101628137BShorten infusion timeSimple structurePressure infusionParenteral nutritionEngineering

The invention belongs to a parenteral nutrition infusion pump, which adopts an extruding device for respectively extruding three infusion tubes in the housing, a fixing groove for fixing the three infusion tubes in the housing, and a housing at the output end of the infusion tube The body is equipped with a bubble detector, a pressure detector and a liquid stop clamp. The upper end of the shell is provided with a left shell cover and a right shell cover opened to both sides, and a liquid crystal display screen and a control keyboard are arranged on one shell cover. The invention can quickly and safely complete the three-channel transfusion process, and has the advantages of simple structure, time-saving and labor-saving, safety and sanitation, convenient use and good effect.

Owner:SHANDESHI MEDICAL TECH BEIJING

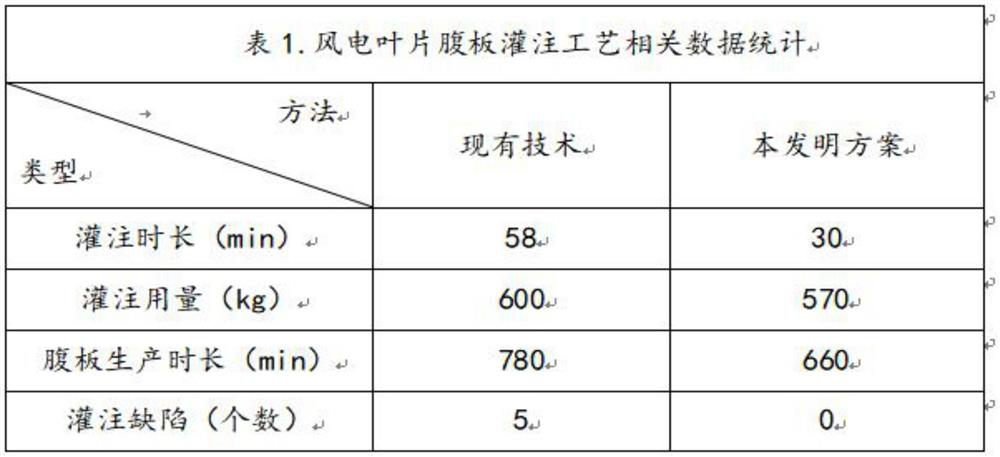

Bilateral pouring process for wind power blade web

PendingCN114474782AShorten infusion timeReduce dosageDomestic articlesStructural engineeringWind power

The invention discloses a wind power blade web bilateral pouring technology which comprises the following steps of foundation laying, flow guide net laying, runner laying and vacuum pouring. According to the scheme, an air exhaust bag is arranged in the middle of a web, pouring runners are arranged on the two sides of the web, and the technical difficulty of 70-meter-level blade web pouring in the prior art is overcome; the web filling time is shortened, the web filling resin consumption is reduced, the web production efficiency is greatly improved, and the problem that at the present stage, 24-hour production cycle components of wind power blades are insufficient in supply is solved.

Owner:SINOMATECH JIUQUAN WIND POWER BLADE CO LTD

Replaceable infusion device

ActiveCN108969833AShorten infusion timeReduce caregiver stressInfusion devicesFlow controlEngineering

The invention discloses a replaceable infusion device, which comprises infusion tubes. The infusion tubes are connected with a regulating box which is provided with a regulation cavity in the center,the upper end face of the regulating box is provided with two liquid inlet holes, and the bottom face of the regulating box is correspondingly provided with two liquid outlet holes. A regulating valveis arranged in the regulating cavity and provided with two infusion through holes, and each liquid inlet hole is communicated with the corresponding liquid outlet hole through the corresponding infusion through hole. The center of the regulating valve is provided with a regulating handle, the regulating box is provided with a regulating groove, the regulating handle penetrates the regulating groove to be positioned outside the regulating box, and the liquid inlet holes and the liquid outlet holes are externally connected with the infusion tubes. The replaceable infusion device has advantagesof flexibility and quickness in replacement of different infusion tubes, time saving, labor saving and reduction of infusion risks.

Owner:苏州市百世康医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com