Waterproof adhesive based on polycaprolactone and preparation method thereof

A polycaprolactone and waterproof adhesive technology, which is applied in polyurea/polyurethane adhesives, adhesives, wax adhesives, etc., can solve the problem of adhesive performance degradation, different adhesive effects, and inability to dissolve various materials and other issues to achieve improved safety and better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

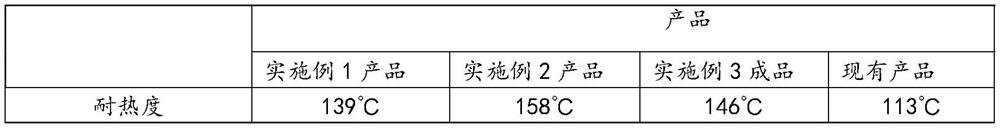

Examples

Embodiment 1

[0019] A polycaprolactone-based waterproof adhesive is composed of the following components in parts by weight: 35 parts of polycaprolactone, 30 parts of paraffin, and 460 parts of EVA.

[0020] At the same time, the invention also discloses a preparation method of a polycaprolactone-based waterproof adhesive, including the following steps:

[0021] S1: First, activate 60 parts of EVA at 400°C, then add 3.5 parts of modifier for stirring and combining, and adjust the temperature to within the range of 65°C, and then obtain a flame retardant material mixture;

[0022] S2: Subsequently, 30 parts of polycaprolactone and 40 parts of paraffin were mixed at high temperature, wherein the temperature range during mixing was 110°C, and the stirring and mixing time was 60 minutes, and the flame retardant material mixture was added during stirring;

[0023] S3: After the high-temperature mixing is completed, dry the mixed material in a vacuum environment at 90°C, where the drying time is...

Embodiment 2

[0030] A polycaprolactone-based waterproof adhesive consists of the following components in parts by weight: 40 parts of polycaprolactone, 40 parts of paraffin, and 45 parts of EVA.

[0031] At the same time, the invention also discloses a preparation method of a polycaprolactone-based waterproof adhesive, including the following steps:

[0032] S1: First, activate 45 parts of EVA at 500°C, then add 3 parts of modifier for stirring and combining, and adjust the temperature to within the range of 60°C, and then obtain a flame retardant material mixture;

[0033] S2: Subsequently, 30 parts of polycaprolactone and 30 parts of paraffin were mixed at high temperature, wherein the temperature range during mixing was 110°C, and the stirring and mixing time was 30 minutes, and the flame retardant material mixture was added during stirring;

[0034] S3: After the high-temperature mixing is completed, dry the mixed material in a vacuum environment at 80°C, where the drying time is 1.5h,...

Embodiment 3

[0040] A polycaprolactone-based waterproof adhesive consists of the following components in parts by weight: 40 parts of polycaprolactone, 40 parts of paraffin, and 60 parts of EVA.

[0041] At the same time, the invention also discloses a preparation method of a polycaprolactone-based waterproof adhesive, including the following steps:

[0042] S1: First, activate 60 parts of EVA at 500°C, then add 4 parts of modifier for stirring and combining, and adjust the temperature to within the range of 65°C, and then obtain a flame retardant material mixture;

[0043] S2: Subsequently, 40 parts of polycaprolactone and 40 parts of paraffin were mixed at high temperature, wherein the temperature range during mixing was 160°C, and the stirring and mixing time was 60 minutes, and the flame retardant material mixture was added during stirring;

[0044] S3: After the high-temperature mixing is completed, dry the mixed material in a vacuum environment at 90°C, where the drying time is 4.5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com