Multiphase composite high-strength high-toughness low-density steel and preparation method thereof

A low-density steel, high-strength and high-toughness technology, applied in the field of multi-phase composite high-strength, high-toughness, low-density steel and its preparation, can solve the problems of small reduction in density, poor control of phase composition, and high cost, and improve comprehensive mechanical properties. , The effect of improving work hardening ability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A multi-phase composite high-strength, high-toughness and low-density steel, the chemical composition of the multi-phase composite high-strength, high-toughness and low-density steel is: 1.10wt.%C, 27.0wt.%Mn, 11.0wt.%Al, 3.0wt.% wt.%Cr, 3.6wt.%Ni, 0.02wt.%Nb, 0.01wt.%S, 0.003wt.%P, the balance being Fe and unavoidable impurities.

[0044] The preparation method of described multiphase composite high-strength high-toughness low-density steel, described preparation method comprises the steps:

[0045] S1, smelting: Proportioning and weighing according to the chemical composition content of the required multi-phase composite high-strength, high-toughness and low-density steel, using a vacuum induction furnace to fully smelt evenly, and casting to obtain an ingot;

[0046] S2, the first homogenization treatment: the ingot in the step S1 is subjected to a high-temperature homogenization treatment with a temperature of 1150° C. and a time of 13 hours;

[0047] S3. Hot forgi...

Embodiment 2

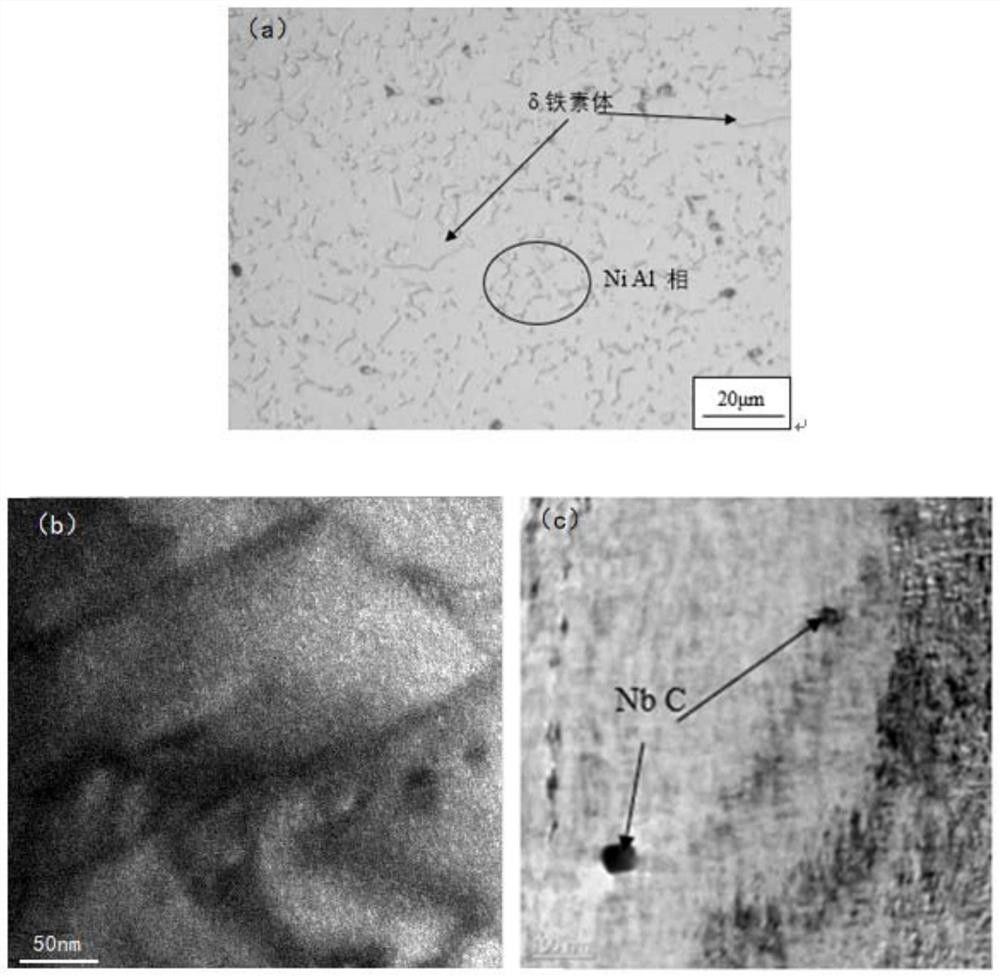

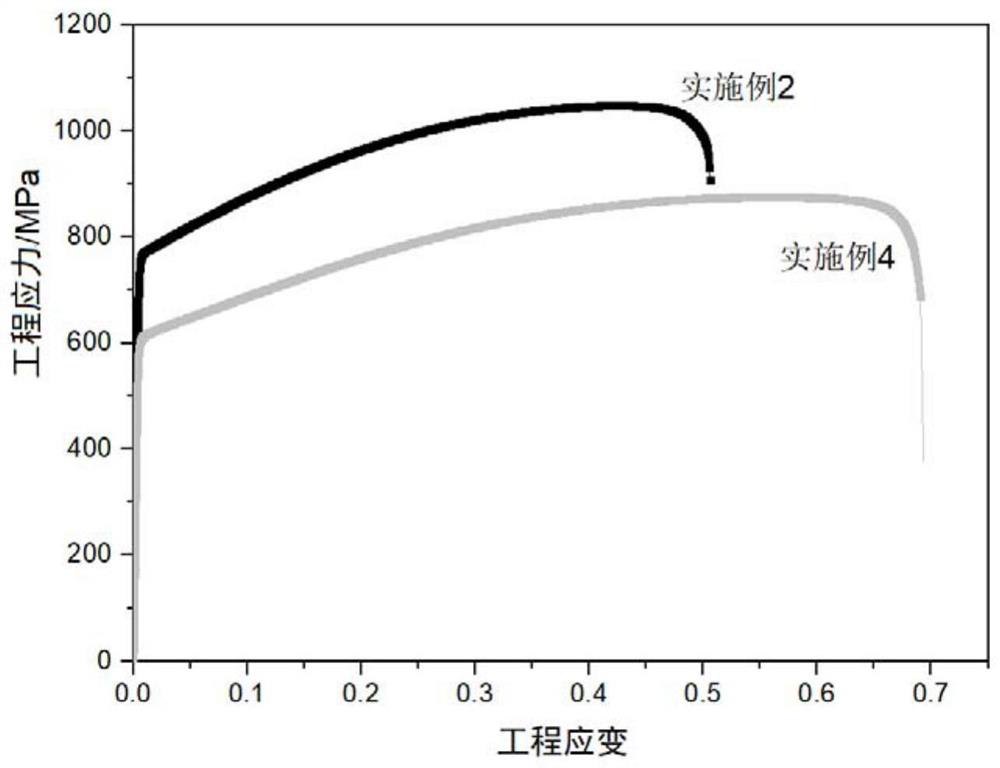

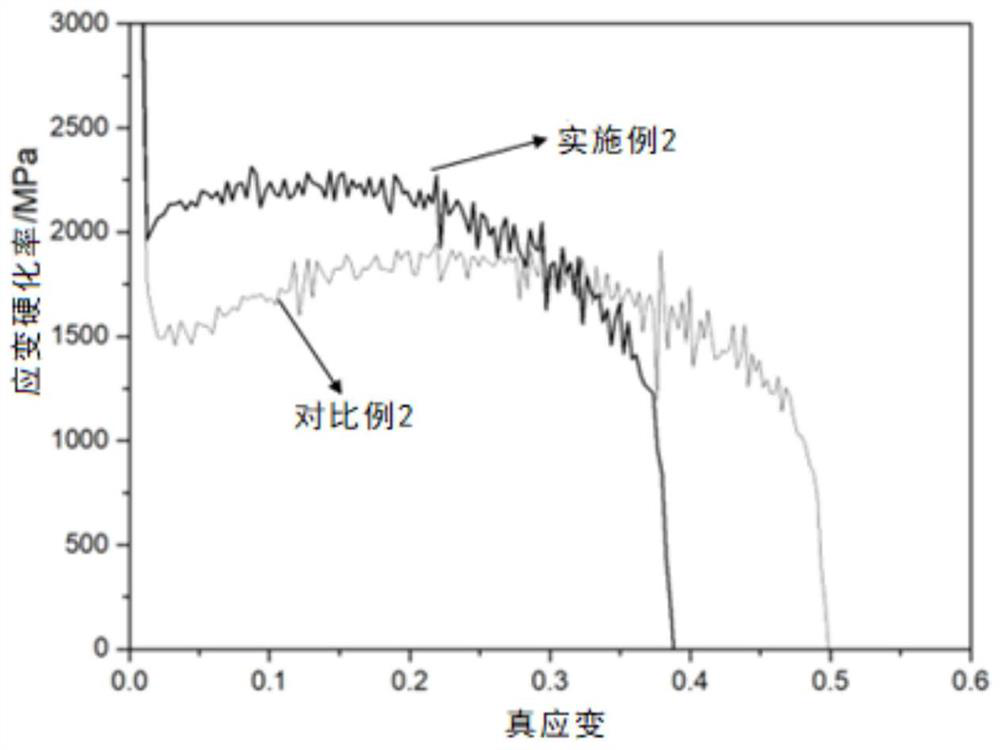

[0057] A multi-phase composite high-strength, high-toughness and low-density steel, the chemical composition of the multi-phase composite high-strength, high-toughness and low-density steel is: 1.08wt.%C, 27.5wt.%Mn, 10.7wt.%Al, 3.3 wt.%Cr, 1.6wt.%Ni, 0.025wt.%Nb, 0.01wt.%S, 0.003wt.%P, the balance is Fe and unavoidable impurities.

[0058] The preparation method of described multiphase composite high-strength high-toughness low-density steel, described preparation method comprises the steps:

[0059] S1, smelting: Proportioning and weighing according to the chemical composition content of the required multi-phase composite high-strength, high-toughness and low-density steel, using a vacuum induction furnace to fully smelt evenly, and casting to obtain an ingot;

[0060] S2, the first homogenization treatment: the ingot in the step S1 is subjected to a high-temperature homogenization treatment with a temperature of 1120° C. and a time of 11 hours;

[0061] S3. Hot forging: fo...

Embodiment 3

[0067] A multi-phase composite high-strength, high-toughness and low-density steel, the chemical composition of the multi-phase composite high-strength, high-toughness and low-density steel is: 1.08wt.%C, 27.3wt.%Mn, 10.5wt.%Al, 3.2 wt.%Cr, 3.2wt.%Ni, 0.04wt.%Nb, 0.005wt.%S, 0.004wt.%P, and the balance is Fe and unavoidable impurities.

[0068] The preparation method of described multiphase composite high-strength high-toughness low-density steel, described preparation method comprises the steps:

[0069] S1, smelting: Proportioning and weighing according to the chemical composition content of the required multi-phase composite high-strength, high-toughness and low-density steel, using a vacuum induction furnace to fully smelt evenly, and casting to obtain an ingot;

[0070] S2, the first homogenization treatment: the ingot in the step S1 is subjected to a high-temperature homogenization treatment with a temperature of 1140° C. and a time of 11 hours;

[0071] S3. Hot forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com