Precast pile reinforcing structure of tunnel and construction method of precast pile reinforcing structure

A technology for strengthening structures and prefabricated piles, which is applied in basic structure engineering, excavation, sheet pile walls, etc., can solve problems such as potential safety hazards, changing the stress of the structure, and destroying the tunnel structure, so as to reduce the difficulty of construction and ensure the bearing capacity of the pile body. force, the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

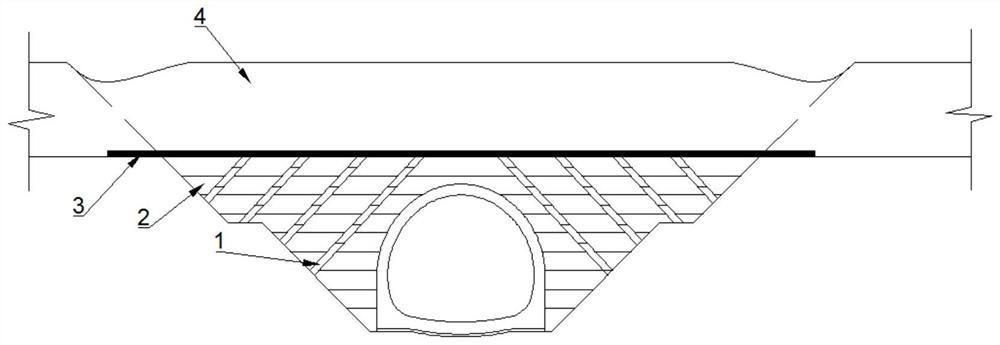

[0027] Such as figure 1 As shown, this embodiment provides a prefabricated pile reinforcement method for tunnels, including:

[0028] Determine the pre-embedded depth of the prefabricated pile 1 according to the construction plan, determine the number of layers of the layered backfill soil layer 2 of the tunnel cut foundation pit, the thickness of each layer of the layered backfill soil layer 2 of the tunnel cut foundation pit, and the edge of the tunnel cut foundation pit The grading angle of the slope is used to carry out the excavation of the tunnel foundation pit;

[0029] The prefabricated pile 1 is prefabricated in the factory, and the prefabricated pile 1 is fixedly arranged on the side slope of the foundation pit in sections, and the excavated foundation pit of the tunnel is backfilled with the soil layer 2 to the grout outlet of the prefabricated pile 1, Connecting the prefabricated piles 1 of the two adjacent sections, and grouting the prefabricated piles 1 of the t...

Embodiment 2

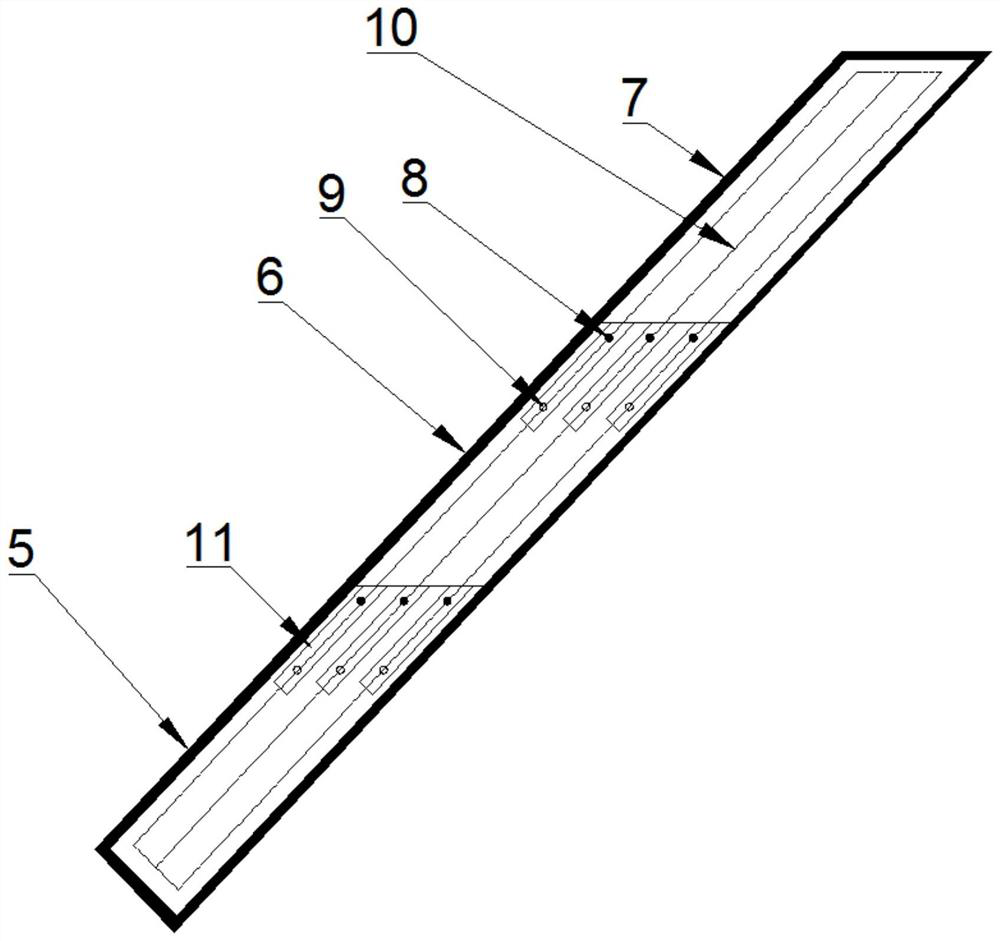

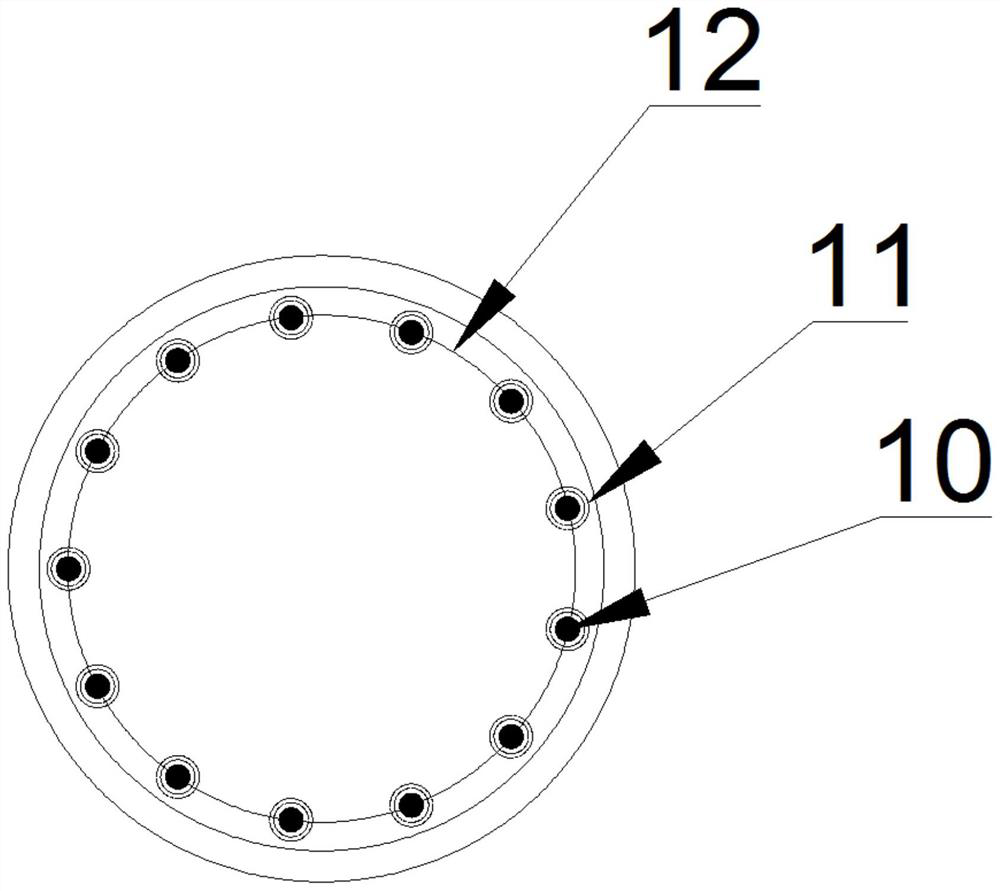

[0033] Such as figure 1 and figure 2 As shown, this embodiment provides a prefabricated pile reinforcement method for tunnels, including:

[0034] Determine the pre-embedded depth of the prefabricated pile 1 according to the construction plan, determine the number of layers of the layered backfill soil layer 2 of the tunnel cut foundation pit, the thickness of each layer of the layered backfill soil layer 2 of the tunnel cut foundation pit, and the edge of the tunnel cut foundation pit The grading angle of the slope is used to carry out the excavation of the tunnel foundation pit;

[0035] The prefabricated pile 1 is prefabricated in the factory, and the prefabricated pile 1 is fixedly arranged on the side slope of the foundation pit in sections, and the excavated foundation pit of the tunnel is backfilled with the soil layer 2 to the grout outlet of the prefabricated pile 1, Connecting the prefabricated piles 1 of the two adjacent sections, and grouting the prefabricated p...

Embodiment 3

[0040] Such as figure 1 As shown, this embodiment provides a prefabricated pile reinforcement method for tunnels, including:

[0041] Determine the pre-embedded depth of the prefabricated pile 1 according to the construction plan, determine the number of layers of the layered backfill soil layer 2 of the tunnel cut foundation pit, the thickness of each layer of the layered backfill soil layer 2 of the tunnel cut foundation pit, and the edge of the tunnel cut foundation pit The grading angle of the slope is used to carry out the excavation of the tunnel foundation pit;

[0042] The prefabricated pile 1 is prefabricated in the factory, and the prefabricated pile 1 is fixedly arranged on the side slope of the foundation pit in sections, and the excavated foundation pit of the tunnel is backfilled with the soil layer 2 to the grout outlet of the prefabricated pile 1, Connecting the prefabricated piles 1 of the two adjacent sections, and grouting the prefabricated piles 1 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com