Supporting assembly for supporting central rotating shaft and central rotating shaft assembly

A technology for supporting components and central rotating shafts, which is applied in the directions of engine components, engine lubrication, turbine/propulsion device lubrication, etc., can solve the problems of large vibration amplitude of the central rotating shaft, and achieve the solution of excessive vibration amplitude and eliminate the stuck slot The effect of the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

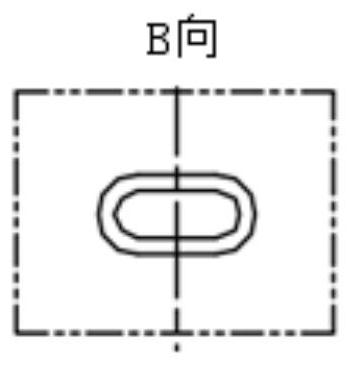

[0048] The rigidity adjusting member adopted in Embodiment 1 includes a first adjusting rod and a loosening preventing member. Such as figure 1 , Figure 4 As shown, the anti-loosening parts include fastening nuts 4 and anti-loosening washers 5, and the anti-loosening parts can also be set as double nuts, anti-loosening nuts and other structures that can achieve anti-loosening effects. The first adjusting rod in the first embodiment is the first anti-rotation adjusting rod 11, which includes a head and a rod, and the head is designed in an oval or rectangular shape.

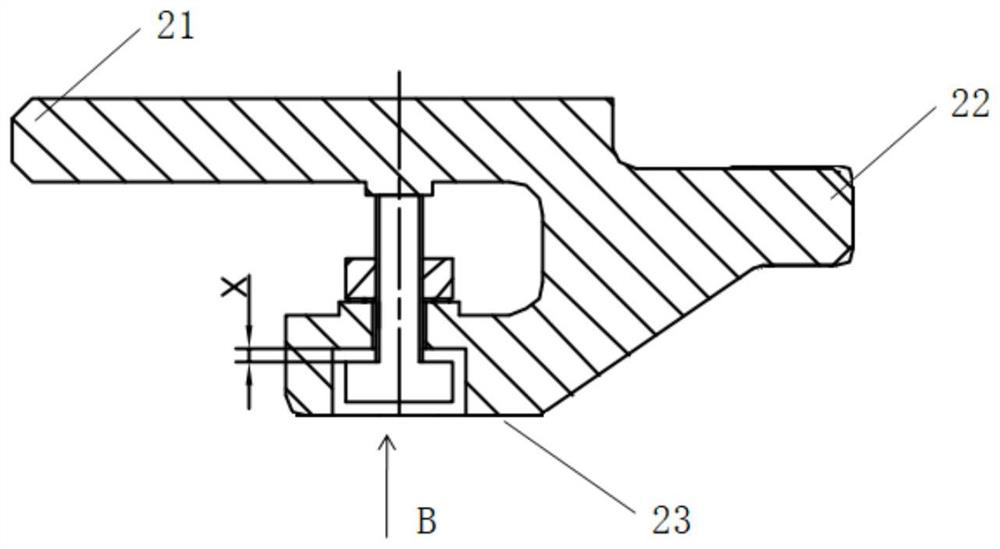

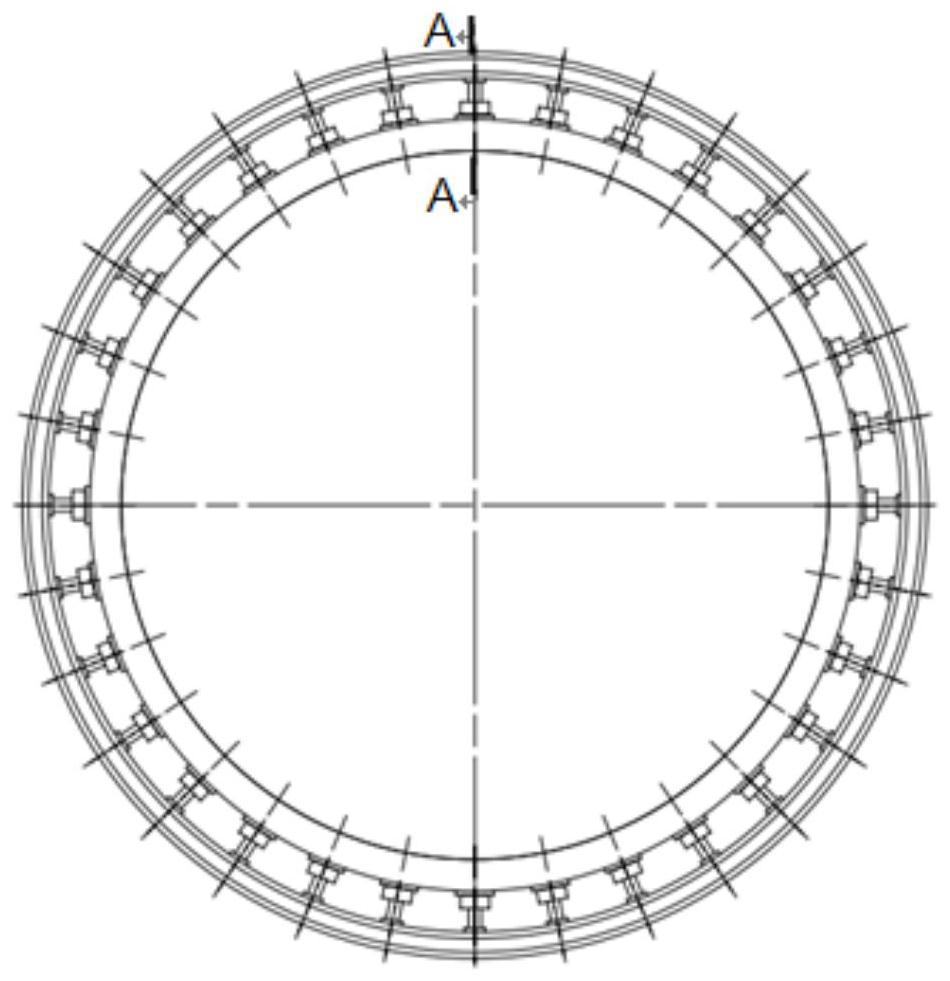

[0049] Such as figure 1 As shown, the first support body 24 includes a first fixed end 21, a second fixed end 22 and a support end 23, the first fixed end 21 is matched with the first slot 9 of the front wheel disc 7, the second fixed end 22 is matched with the The second card slot 10 of the rear wheel disc 8 fits, and the supporting end 23 supports the central rotating shaft 1 . The first fixed end 21 and th...

Embodiment 2

[0056] Embodiment 2 On the basis of Embodiment 1, the adjustment method of the adjustment component is changed. The adjustment assembly is an elastic adjustment member, including a second adjustment rod, a compression pad 2, and a compression spring 6, and the second adjustment rod is arranged in the U-shaped opening through the compression pad 2 and the compression spring 6. The second adjusting rod in the second embodiment is the second anti-rotation adjusting rod 13, which includes a head and a rod. The head is oblong or rectangular in design to prevent the rod from loosening. The second anti-rotation adjusting rod passes through the support end 23 , and the compression spring 6 is pressed against the side surface of the first fixed end 21 through the anti-loosening piece and the pressing pad 2 .

[0057] Both ends of the pressing pad 2 are provided with annular grooves, one end is used to support the rod end surface of the second anti-rotation adjusting rod 13 , and the ot...

Embodiment 3

[0062] Embodiment 3 On the basis of Embodiment 2, the position of adjusting the gap X is changed. The adjustment assembly is an elastic adjustment member, including a second adjustment rod, a pressing pad 2 and a compression spring 6 . The second adjusting rod in the third embodiment is the second adjusting rod 14 with holes. The second adjusting rod 14 with a hole cooperates with the compression pad 2 and the compression spring 6 to adjust the rigidity of the support assembly. The head of the second adjusting rod 14 with a hole is arranged at a position away from the central rotating shaft 1 , the rod passes through the first fixed end 21 , and the compression spring 6 is pressed on the side surface of the supporting end 23 by the compression pad 2 . The pressing block 2 has two grooves, the upper groove is used to support the second adjusting rod, and the lower groove is used to define the top surface of the compression spring 6 . The compression spring 6 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com