PWM (Pulse Width Modulation) control method and system for prolonging service life of array high-speed switch valve

A high-speed switching valve and control method technology, applied in the field of digital hydraulic control, can solve the problems of inconsistent switching times, valve port wear, accelerated aging of coils, etc., and achieve the effect of reducing the total switching times and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

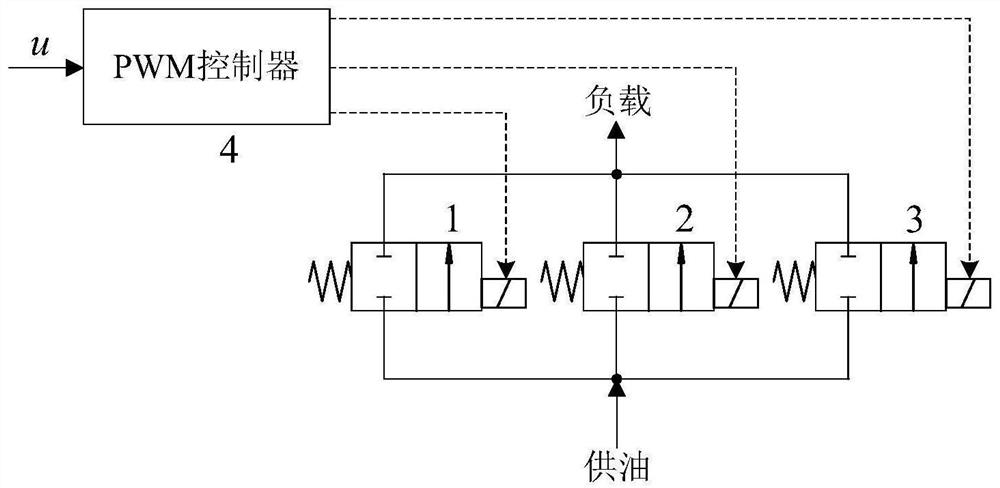

[0032] Such as figure 1 As shown, the PWM controller 4 is used to control the working state of the array high-speed switching valve. The array high-speed switching valve is composed of the first switching valve 1, the second switching valve 2 and the third switching valve 3 in parallel, and the first switching valve 1. The second on-off valve 2 and the third on-off valve 3 are three on-off valves with the same flow gain.

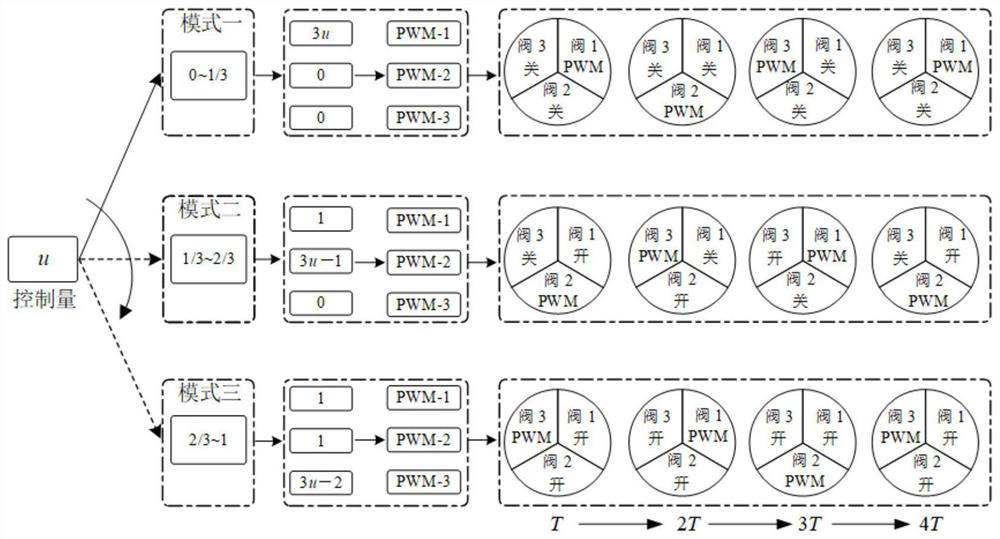

[0033] Such as figure 2 As shown, a kind of PWM control method that improves the service life of array high-speed switching valve described in the present invention, specifically comprises the following steps:

[0034](1.1) Divide the control variable u into three ranges on average, and each range corresponds to a mode, including mode 1, mode 2, and mode 3. The range of the control quantity u is 0-1, then when the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com