Flame detection device with good protection performance for hot blast stove

A flame detection device and technology for protection performance, which is applied in the field of flame detection devices for hot blast stoves, can solve problems such as heating of internal circuits, poor protection effect, melting of insulating layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

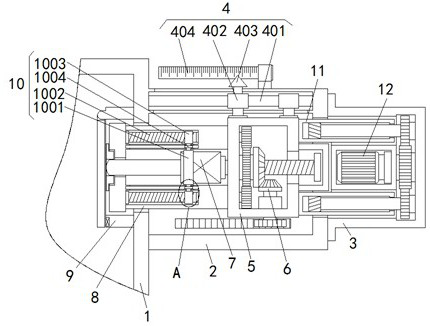

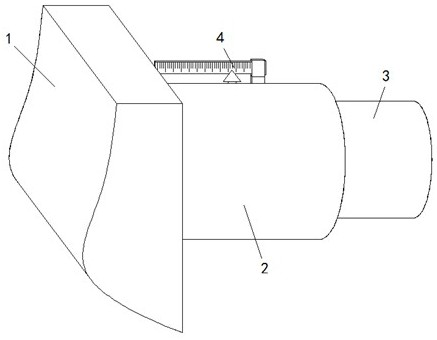

[0035] Embodiment one, by Figure 1-4 A flame detection device for a hot blast stove with good protective performance is provided. The present invention includes a furnace body 1, an installation shell 2 is fixedly connected to the right side of the furnace body 1, a transmission shell 3 is fixedly connected to the right side of the installation shell 2, and a transmission shell 3 is fixedly connected to the right side of the installation shell. 2 is provided with a sliding device 4 with one end extending to the top of the installation case 2. The bottom of the sliding device 4 is fixedly connected with the gear case 5 located inside the installation case 2. The inside of the gear case 5 is provided with an extension device 6. The extension device 6 The left side is provided with a flame detector 7 located on the left side of the gear housing 5, and the left side of the gear housing 5 is fixedly connected with a protective shell 8 that extends to the inside of the furnace body ...

Embodiment 2

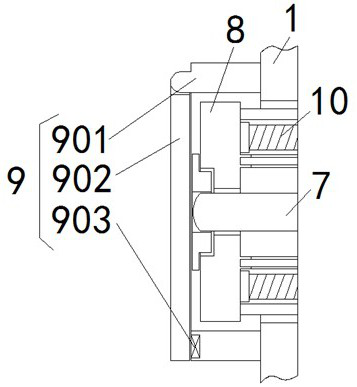

[0057] Embodiment two, by figure 1 and image 3 Provided, the left side of the gear housing 5 is fixedly connected with a protective shell 8 that extends to the inside of the furnace body 1 and is located outside the flame detector 7, and the right side wall of the inner cavity of the furnace body 1 is provided with a closure located outside the protective shell 8. device9.

[0058] The outer side of the protective case 8 is wrapped with fire-resistant glass, and the left side of the protective case 8 is fixedly connected with a dust removal ring in contact with the outer side of the probe, and the dust removal ring is made of fire-resistant rubber;

[0059] Refractory rubber can maintain softness and sealing while possessing fire and heat resistance;

[0060] Closing device 9 comprises fixed ring 901, and fixed ring 901 is fixedly connected with the inner cavity right side wall of furnace body 1, and fixed ring 901 is positioned at the outside of protective shell 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com