Novel balance channel flowmeter

A flow meter and balance technology, which is applied in the field of new balance channel flow meters, can solve the problems of inaccurate measurement, loss of ideal shape of throttle parts, and difficulty in timely detection of shape changes, etc., to achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

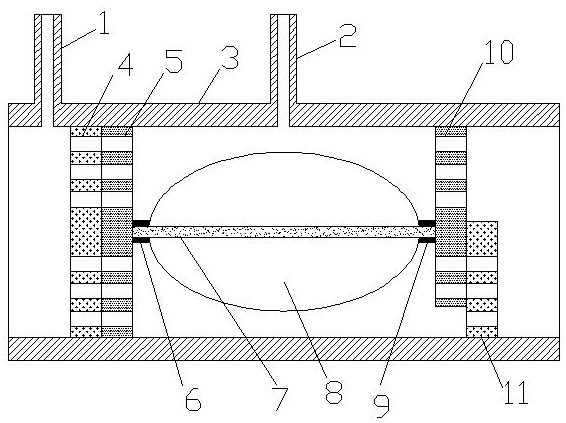

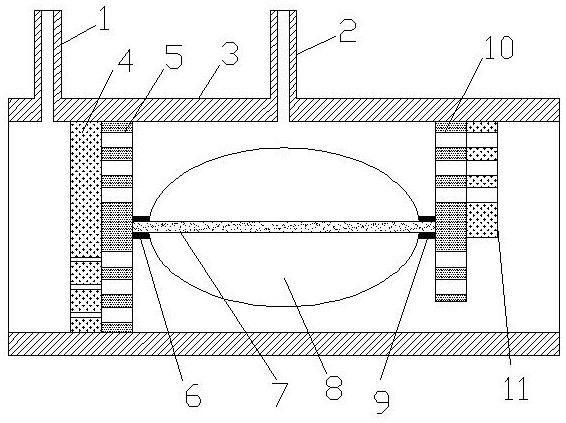

[0030] figure 1 and figure 2 The middle is a new balance channel flowmeter, 1. Pressure tube A, 2. Pressure tube B, 3. Measuring pipe, 4. Front rotating plate, 5. Front balance body, 6. Rotating shaft, 7. Scraper , 8. Throttle, 9. Round shaft, 10. Rear balance body, 11. Rear rotating plate.

[0031] It includes a measuring pipeline, a controller, a differential pressure transmitter and an ellipsoid-shaped throttling piece. The measuring pipeline is provided with a front balance body and a rear balance body, and the throttle piece is arranged on the front balance body and the rear balance body. Between the bodies, the measuring pipes on both sides of the front balance body are respectively provided with a pressure-taking tube A and a pressure-taking tube B, both of which are connected to a differential pressure transmitter, and the differential pressure The transmitter is connected to the controller, the front balance body is evenly distributed with a number of through holes...

example 2

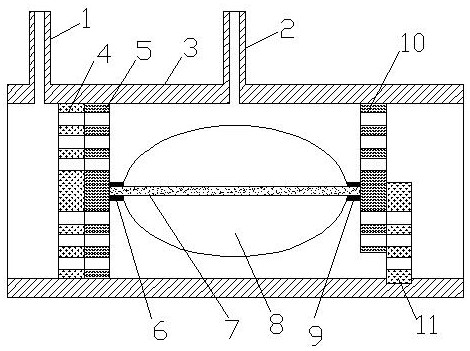

[0038] Figure 3 to Figure 5 The middle one is a new balance channel flowmeter, in the figure: 1. Pressure pipe A, 2. Pressure pipe B, 3. Measuring pipe, 4. Front rotating plate, 5. Front balance body, 6. Rotating shaft, 7 .Scraper, 8. Throttle, 8.1. Outer shell, 8.2. Inner shell, 8.3. Connecting column, 9. Round shaft, 10. Rear balance body, 11. Rear rotating plate, 12. Liquid sensor, 13. Bee Sound the alarm.

[0039] It includes a measuring pipeline, a controller, a differential pressure transmitter and an ellipsoid-shaped throttling piece. The measuring pipeline is provided with a front balance body and a rear balance body, and the throttle piece is arranged on the front balance body and the rear balance body. Between the bodies, the measuring pipes on both sides of the front balance body are respectively provided with a pressure-taking tube A and a pressure-taking tube B, both of which are connected to a differential pressure transmitter, and the differential pressure Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com