Finish machining equipment for surface of die steel and finish machining process of finish machining equipment

A technology of mold steel and equipment, applied in the field of finishing equipment on the surface of mold steel, can solve the problems of slow gas flow, inability to effectively absorb shoe boxes, and reduce the practicability of shoe boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

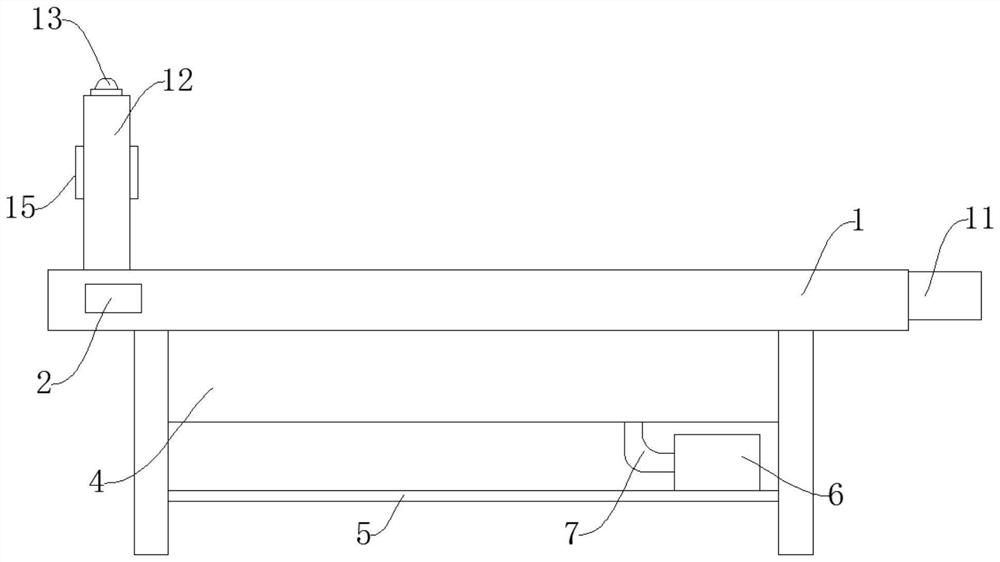

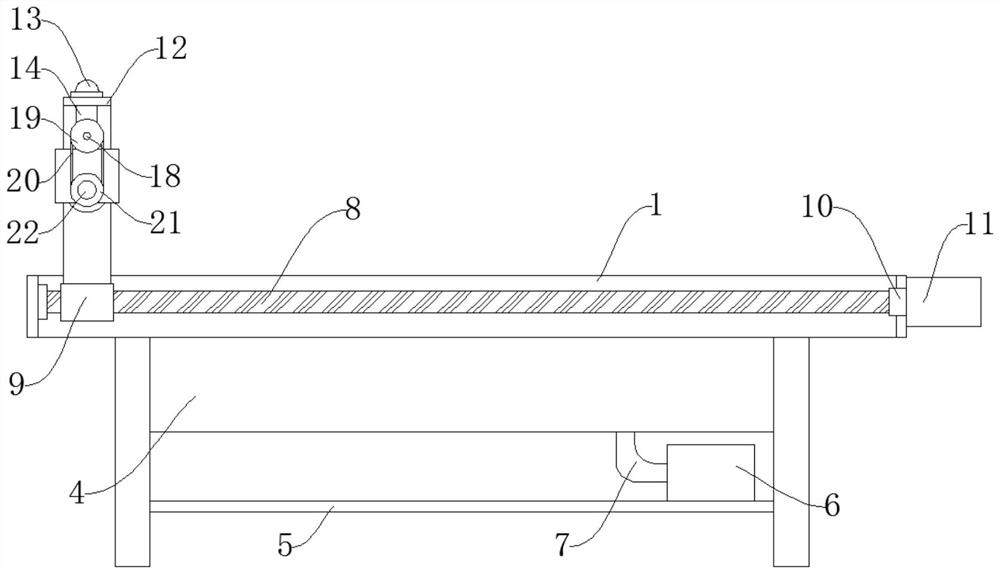

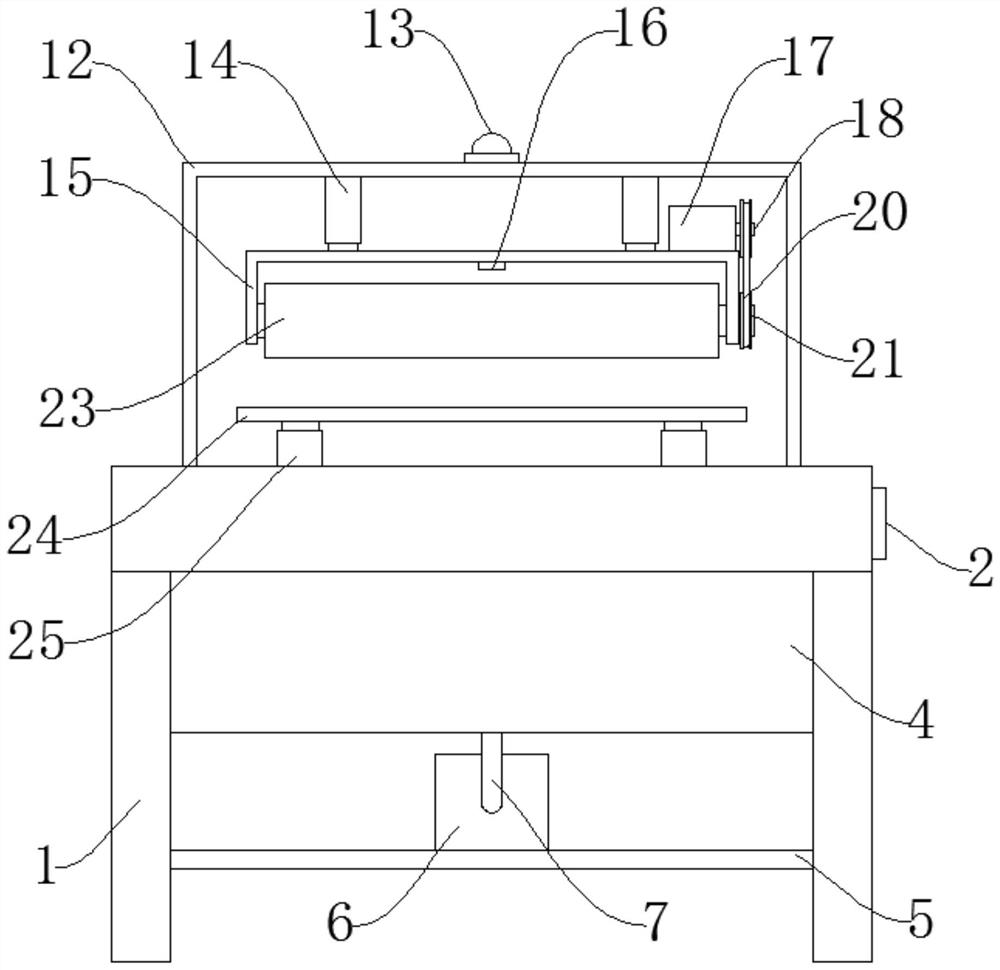

[0035] The present invention will be further described below in conjunction with accompanying drawing:

[0036] like Figure 1-Figure 4As shown, a finishing equipment for the surface of mold steel includes a frame 1, a threaded shaft 8 and a support frame 12. An operation panel 2 is installed on one side of the frame 1, and the staff can use the operation panel 2 to pair the device For control, the upper middle part of the frame 1 is fixed with a load-bearing grid 3, the load-bearing grid 3 can carry the mold steel, and a collection box 4 is installed under the frame 1, and the polished debris passes through the load-bearing Holes on the grille 3 fall into the collection box 4 for collection, and a support plate 5 is fixed below the collection box 4, and the support plate 5 can support the fan 6. On the support plate 5 A blower fan 6 is installed, and the blower blower 6 can extract debris. One side of the blower blower 6 is connected with a suction pipe 7, and the suction pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com