Intelligent flue energy recycling system

An energy recovery and energy collection technology, applied in waste heat treatment, furnaces, furnace control devices, etc., can solve problems such as production blockage, economic loss, flue blockage, etc., to save energy, protect the environment, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

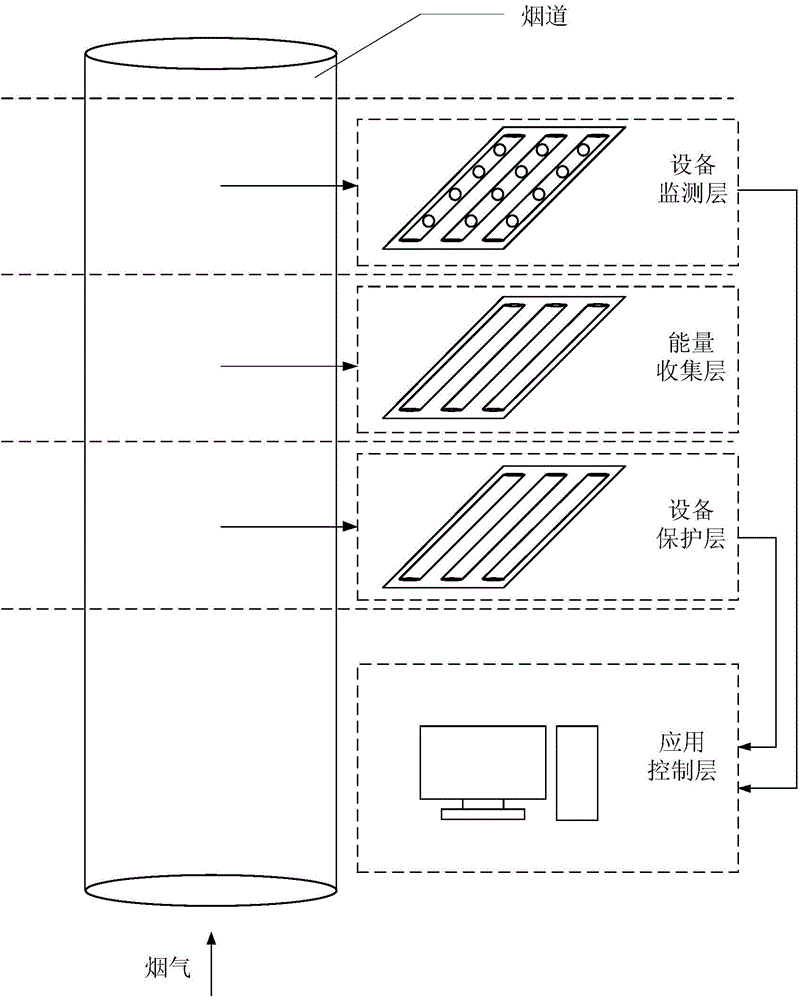

[0027] like figure 1 It is a structural schematic diagram of an embodiment of an intelligent flue energy recovery system of the present invention, including an energy collection layer for waste heat collection, an equipment protection layer for protecting the transducer tube, and equipment monitoring for detecting the working state of the transducer tube layer and an application control layer for collecting information and controlling; wherein, the device protection layer is located at the bottom of the system close to the flue, the energy collection layer is located on the upper part of the device protection layer, and the device monitoring layer is located on the upper part of the energy collection layer, the application control layer is located in the control room outside the flue, and the equipment protection layer and the equipment monitoring layer are electrically connected to the application control layer.

Embodiment 2

[0029] On the basis of Embodiment 1, further, the application control layer includes a signal acquisition unit and a server unit, and the signal acquisition unit is used to collect signals of the equipment protection layer and the equipment monitoring layer, and send the signals to the server unit, and the server unit includes a A computer, the server unit displays the status of the sensor of the device protection layer and the device detection layer. When the status of the sensor of the device protection layer or the device detection layer is abnormal, the server unit will indicate the fault area and prompt for maintenance.

[0030] The energy collection layer includes at least one layer of transduction tube network. The transduction tube network is composed of several transduction tubes, which can be composed of a square network formed in parallel.

[0031] The equipment protection layer includes a protection tube network and a protection tube monitoring unit. The protection ...

Embodiment 3

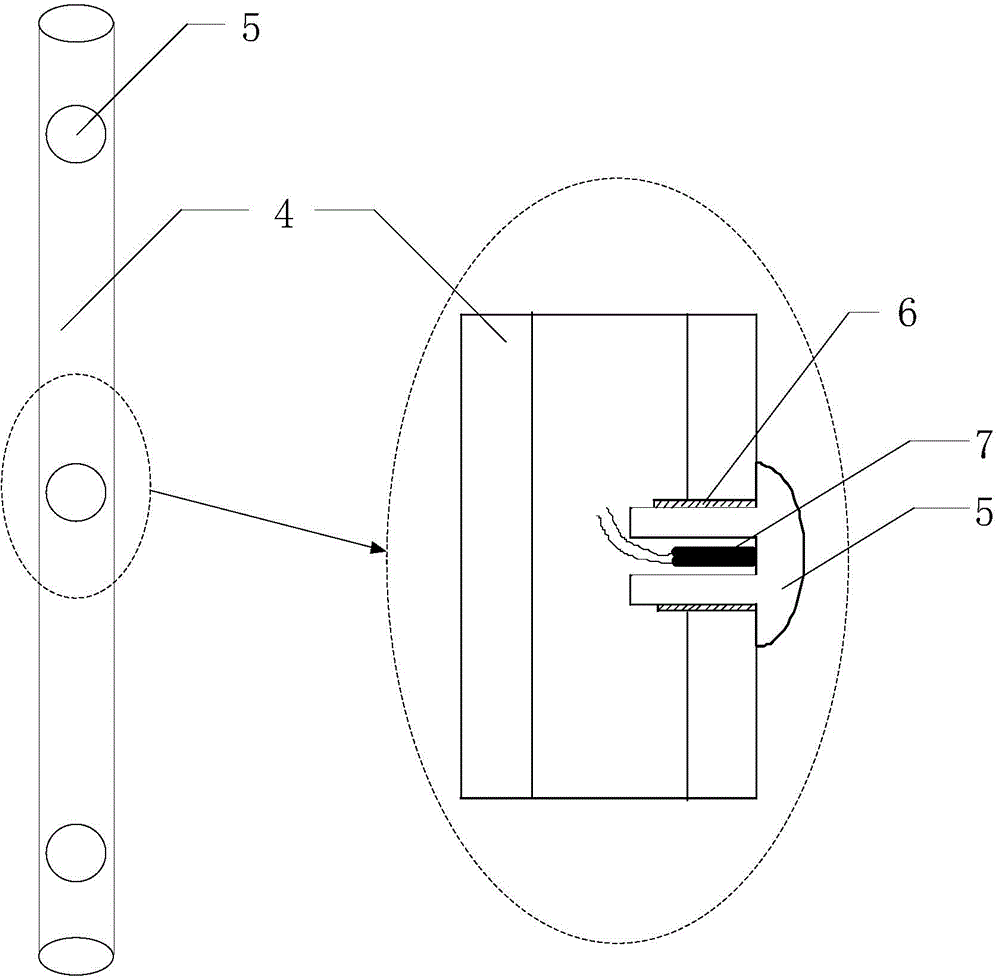

[0037] On the basis of embodiment 2, further, such as image 3 It is a schematic diagram of an embodiment of the second protection tube. The second protection tube includes a second protection tube body 4, several hollow screws 5, several screw holes 6 and several thermocouples 7, and the thermocouples 7 are fixed in the hollow with thermally conductive silica gel. Inside the screw 5, the hollow screw 5 is fixed in the screw hole 6, and the wire of the thermocouple 7 is electrically connected to the signal acquisition unit of the application control layer along the inside of the second protection tube. The hollow screw 5 is made of steel, which has good thermal conductivity, is abundant in the market, is relatively cheap, and is easy to process; of course, other metal materials such as aluminum, copper or silver can also be used.

[0038] Under normal circumstances, the temperature in the flue is higher than 100 degrees Celsius, so the leaked moisture will be vaporized in an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com