Waterproof and dustproof integrated testing machine for subway axle box bearing

An axle box bearing, waterproof and dustproof technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., to meet the test requirements, stable water flow, and good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

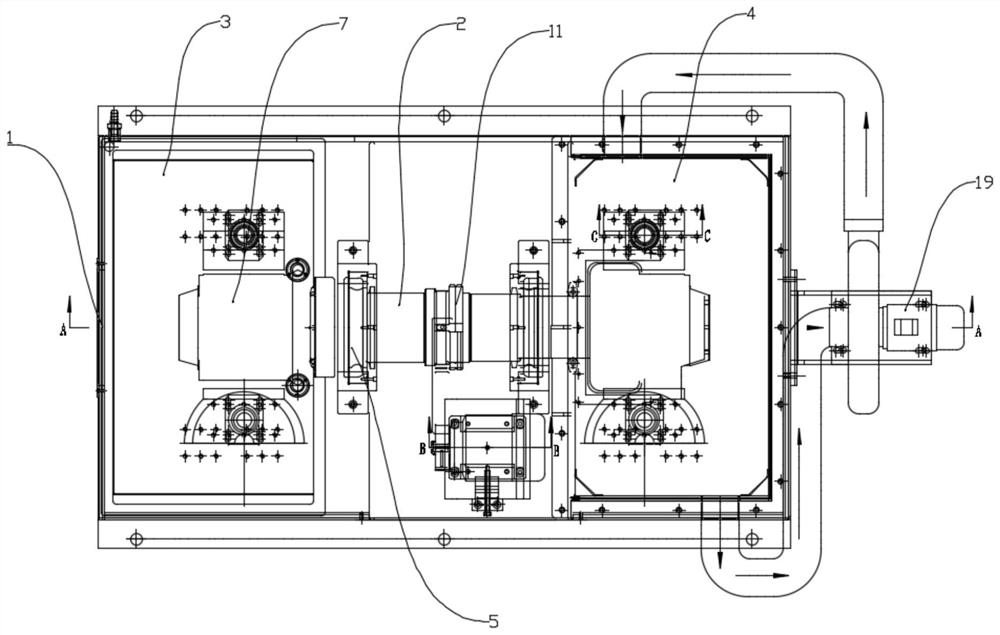

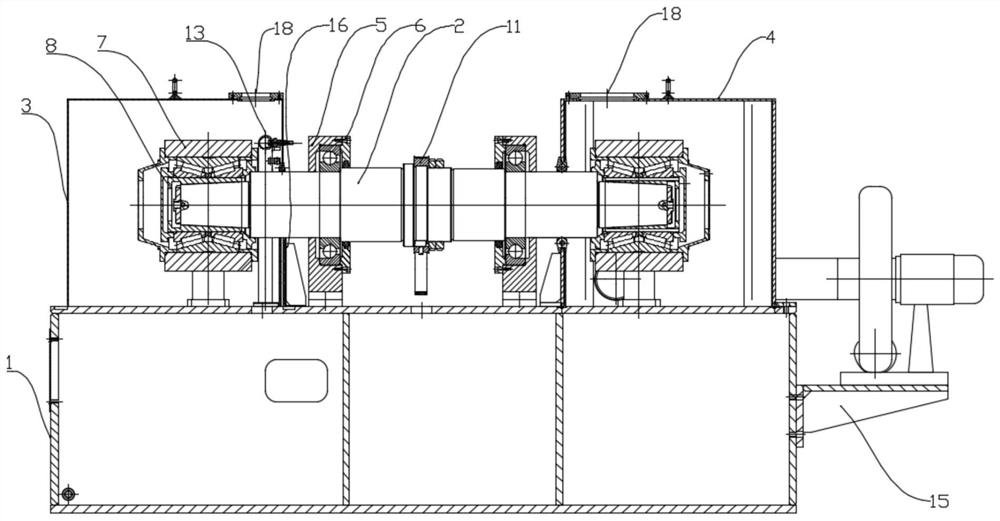

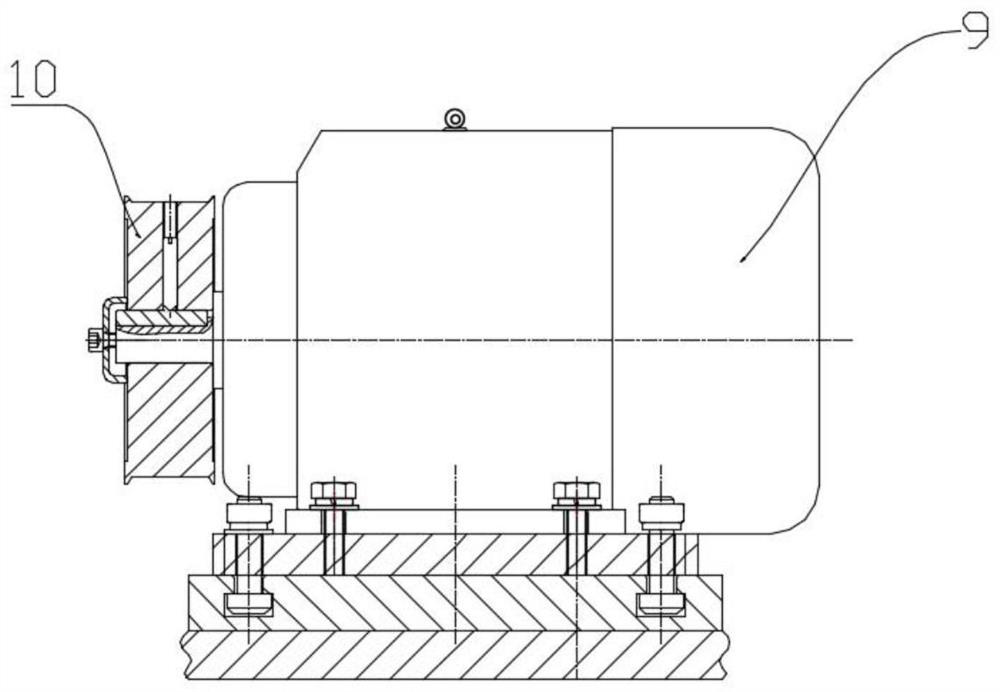

[0026] Such as Figure 1-Figure 5 as shown,

[0027] An integrated waterproof and dustproof test machine for subway axle box bearings, including a body 1, a main shaft 2, a waterproof test box 3 and a dustproof test box 4, the main shaft 2 is installed on the body 1 through a bearing seat 5, and the main shaft 2 is connected to a power transmission device And can rotate around bearing seat 5 under the drive of power transmission device, the quantity of bearing seat 5 is two, is provided with angular contact ball bearing in bearing seat 5, is provided with bearing gland 6 on bearing seat 5. The bearing seat 5 is processed from a high-quality steel, and is used to install the supporting bearing of the main shaft 2 - an angular contact ball bearing. The bearings are used in pairs, installed back to back, and bear a large axial force. The bearing seat is used in conjunction with the main shaft and the bearing gland to realize the axial positioning of the angular contact ball bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com