Quartz sand purification equipment for quartz rod production and working method

A quartz sand and quartz rod technology, applied in the field of quartz sand purification, can solve the problems of lack of a device for separating cleaning agent from quartz sand and iron-containing impurities, lack of a device for recycling the cleaning agent, waste of resources, etc., and achieves a simple equipment structure. Reasonable, stable water flow, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

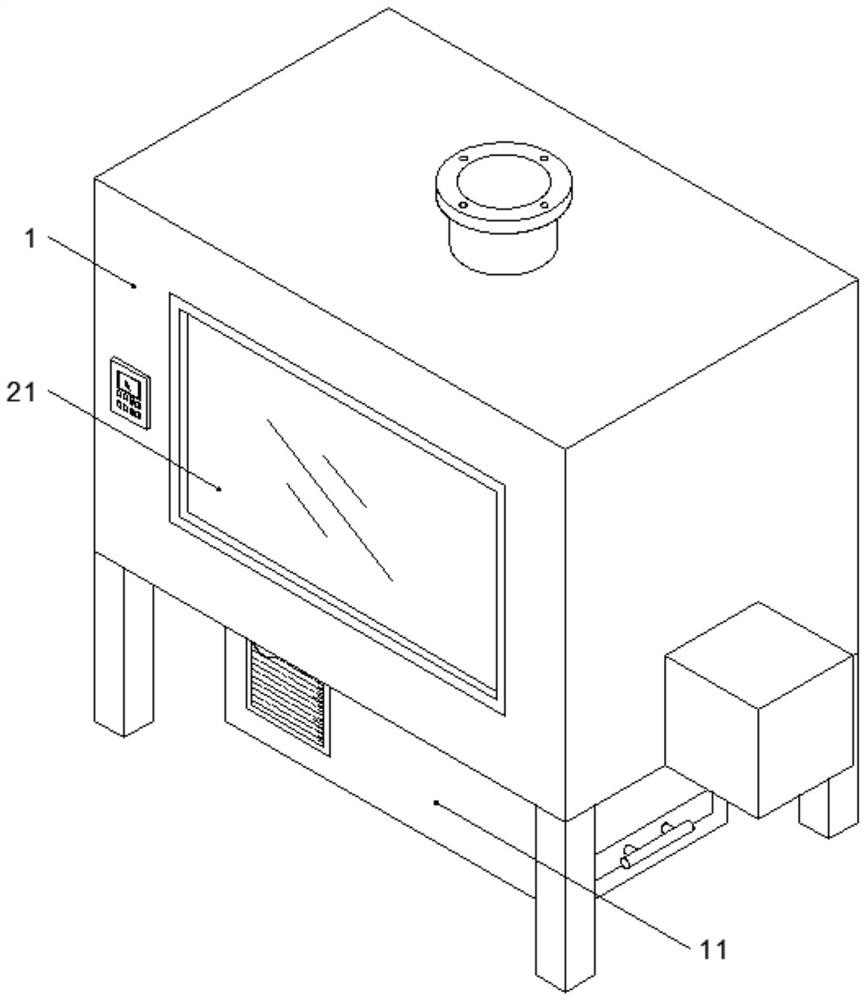

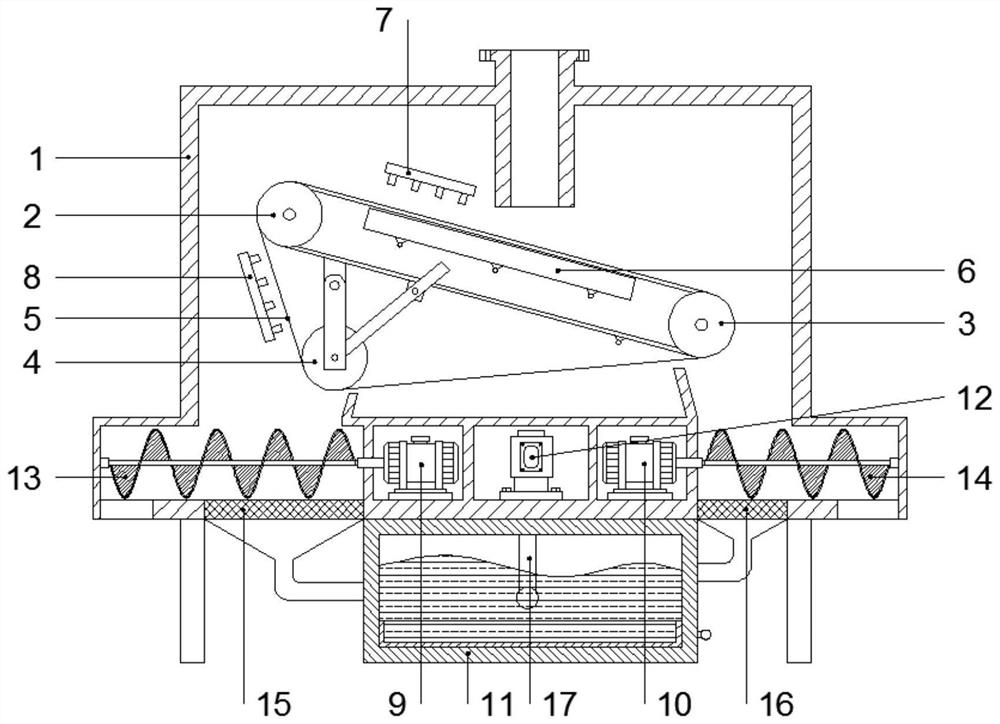

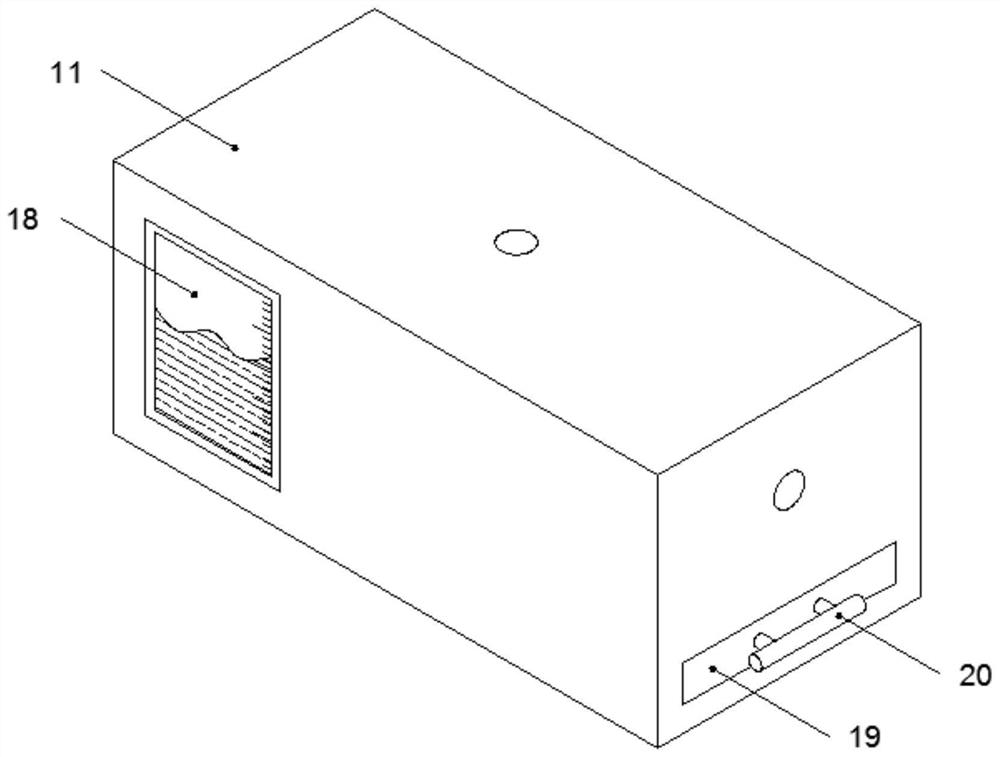

[0024] Example: such as Figure 1-3 As shown, a quartz sand purification equipment and working method for the production of quartz rods in the present invention includes a cabinet 1, a drive roller 3 is fixedly installed on one side of the cabinet 1, and the side inside the cabinet 1 is away from the side of the drive roller 3 The driven roller 2 is fixedly installed. The inner side of the cabinet 1 is fixedly installed with the tension roller 4 near the bottom of the driven roller 2. The driven roller 2, the driving roller 3 and the tension roller 4 are sleeved on the outside. There is a conveyor belt 5, an electromagnet 6 is fixedly installed between the driven roller 2 and the driving roller 3, a first cleaner 7 is arranged on the top of the conveyor belt 5 between the driven roller 2 and the driving roller 3, and the driving roller One side of the conveyor belt 5 between the cylinder 3 and the tension roller 4 is provided with a second cleaner 8, and the inside of the cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com