Pressure unbalance emergency processing system for aircraft test and processing method thereof

A technology for emergency treatment and aircraft testing, which is applied in the direction of aircraft component testing, machine/structural component testing, control/regulation systems, etc. It can solve the damage of laboratory building structures, threats to personnel, safety of test pieces and equipment, and increase in oil and gas concentration and other problems, to achieve the effect of improving the speed of pressure relief and rescue convenience, improving reliability and safety, and improving the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

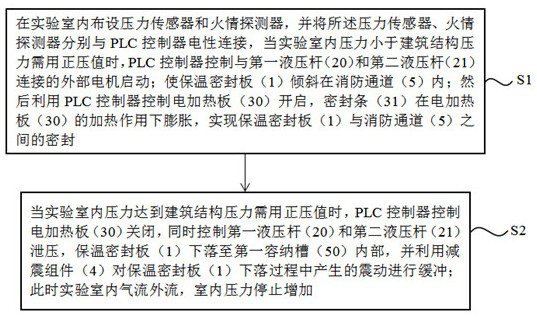

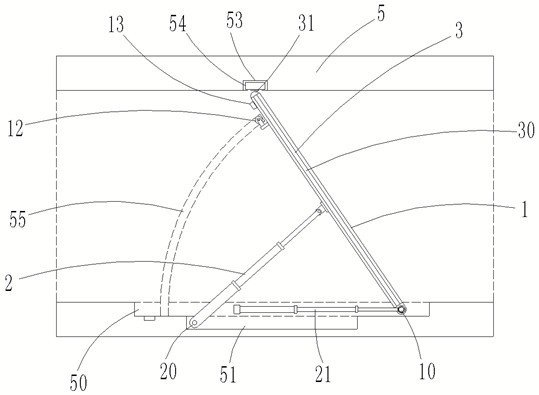

[0038] Such as figure 2 , 3 , a kind of aircraft test pressure imbalance emergency treatment system shown in , 4, 6, comprises insulation sealing plate 1, driving assembly 2, sealing assembly 3, damping assembly 4 and PLC controller; 5 inside, the longitudinal section of the fire exit 5 is a regular quadrilateral, and the shape of the heat preservation and sealing plate 1 is compatible with the fire exit 5; Sliding grooves 52 are arranged on both sides of the first containing groove 50; the second containing groove 51 is located at the lower end of the first containing groove 50, and the two sides of the thermal insulation and sealing plate 1 are slid and engaged inside the sliding groove 52 through the rotating shaft 10, and the thermal insulation and sealing plate 1 can be accommodated in the second Inside of a holding tank 50;

[0039] Such as figure 2 , 3 , 5, the drive assembly 2 includes a first hydraulic rod 20 and a second hydraulic rod 21, one end of the first hyd...

Embodiment 2

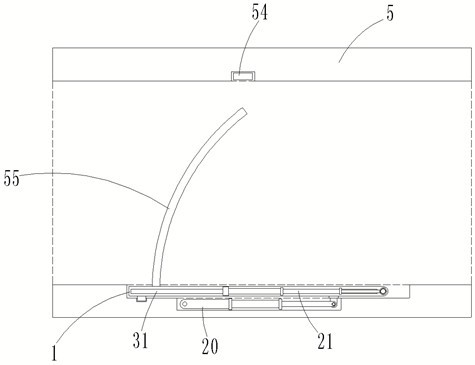

[0045] What this embodiment records is the processing method of a kind of aircraft test pressure unbalance emergency treatment device of embodiment 1, comprises the following steps:

[0046] S1. Arrange pressure sensors and fire detectors in the laboratory, and electrically connect the pressure sensors and fire detectors to the PLC controller respectively. When the pressure in the laboratory is lower than the positive pressure value required by the building structure, the PLC The controller controls the start of the external motor connected with the first hydraulic rod 20 and the second hydraulic rod 21; the thermal insulation sealing plate 1 is tilted in the fire exit 5; then the PLC controller is used to control the opening of the electric heating plate 30, and the sealing strip 31 The heating plate 30 expands under the action of heating to realize the sealing between the thermal insulation sealing plate 1 and the fire exit 5;

[0047] S2. When the pressure in the laboratory...

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] Such as figure 2 , 9 As shown, the inner wall of the fire exit 5 is provided with an auxiliary sealing groove 53, and the inside of the auxiliary sealing groove 53 is provided with a sealing tape 54. The sealing tape 54 is hollow inside and connected to an external air source device; when the heat preservation sealing plate 1 is in a sealed state, The sealing strip 54 corresponds to the position of the sealing strip 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com