Device convenient for bright spot detection of lithium battery diaphragm

A lithium battery diaphragm and detection device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of easy omission and shadow, and achieve the effect of preventing scattering and detachment, uniform irradiation, and easy to observe the diaphragm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

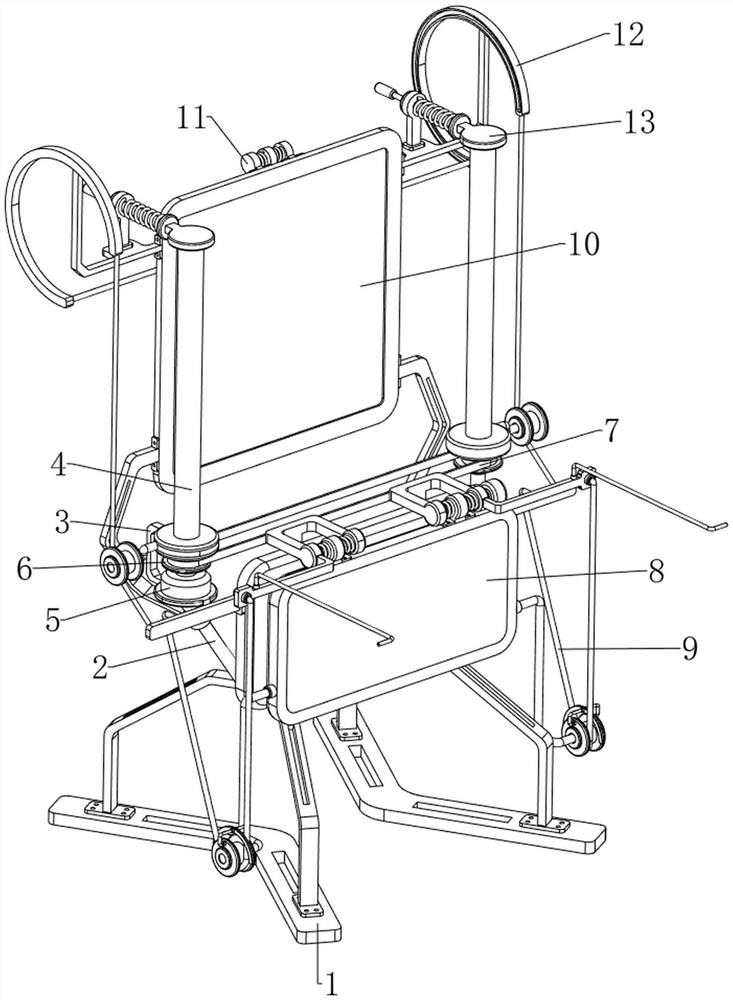

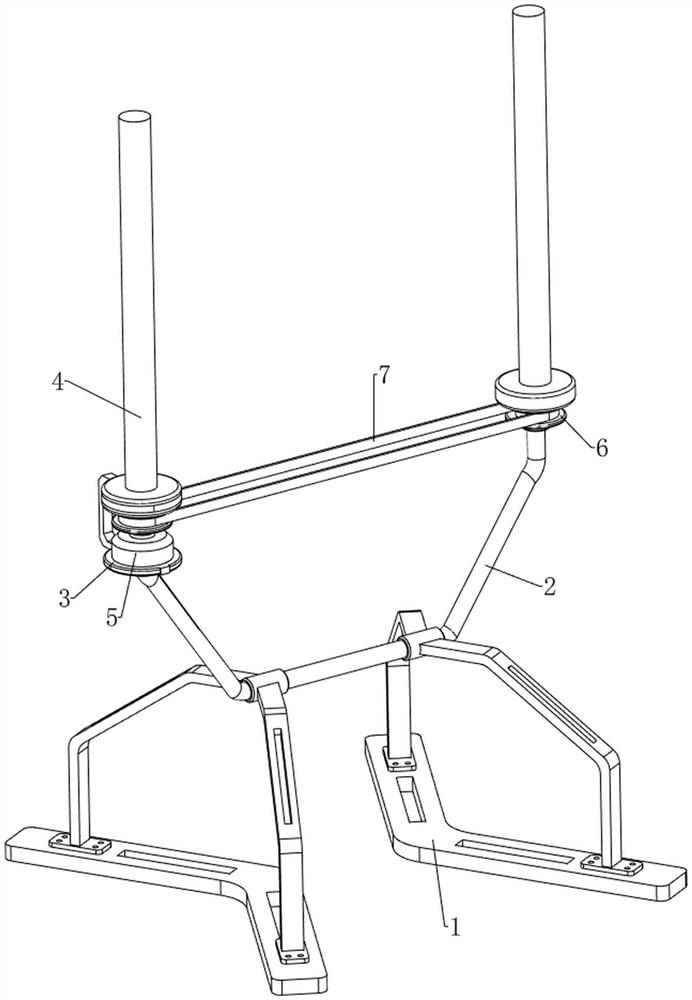

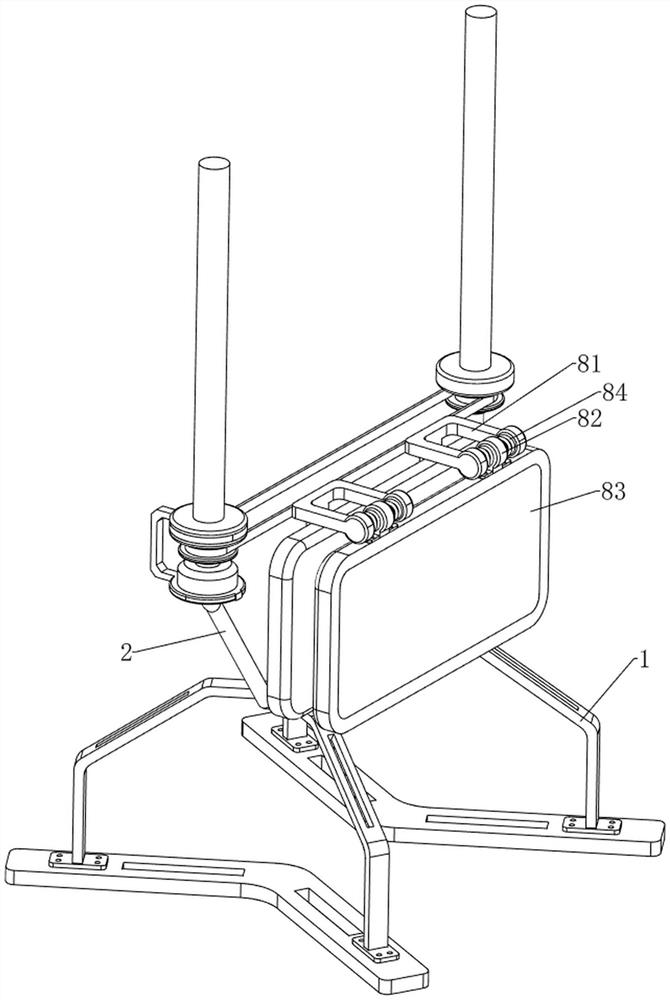

[0038] A bright spot detection device for lithium battery diaphragm, in Figure 1-8 As shown in , it includes a support frame 1, a U-shaped bar 2, a first fixed block 3, a discharge bar 4, a driving motor 5, a pulley 6, a flat belt 7, a detection mechanism 8 and an unfolding mechanism 9, and the lower part of the U-shaped bar 2 The left and right sides are connected with the support frame 1, and the bottoms of the two support frames 1 are coated with anti-slip glue, which can increase the friction between the support frame 1 and the ground, will not move easily, and increase stability. The top left side of the U-shaped bar 2 is welded There is a first fixed block 3, on which a drive motor 5 capable of automatically rewinding and unwinding the diaphragm roll is mounted on the first fixed block 3, and the upper part of the first fixed block 3 and the top right side of the U-shaped bar 2 are both rotatable There is a discharge rod 4 for placing the diaphragm roll for post-rolling...

Embodiment 2

[0043] On the basis of Example 1, in figure 1 and Figure 9 As shown in , it also includes a brightening mechanism 10. The brightening mechanism 10 includes a fifth fixed block 101 and a light-transmitting plate 102. The fifth fixed block 101 is welded on the left and right sides of the upper part of the U-shaped bar 2, and the two fifth fixed blocks 101 are welded. A light-transmitting plate 102 capable of blocking a part of light is connected between the upper sides of the fixing blocks 101 , and the light-transmitting plate 102 is located at the rear side of the two discharge rods 4 .

[0044] After people connect the first lighting lamp 83 with the second lighting lamp 87 and turn on the power supply, the first lighting lamp 83 and the second lighting lamp 87 illuminate the diaphragm at the same time, and the light intensity is relatively strong. People can stand behind the light-transmitting plate 102 and pass The transparent plate 102 is used to check the diaphragm, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com