Light splitting plate combination structure

A technology of combined structure and beam splitter, applied in optics, nonlinear optics, instruments, etc., can solve the problem of increasing the thickness of the backlight module, and achieve the effect of reducing the thickness, reducing the dark area, and eliminating the dark area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

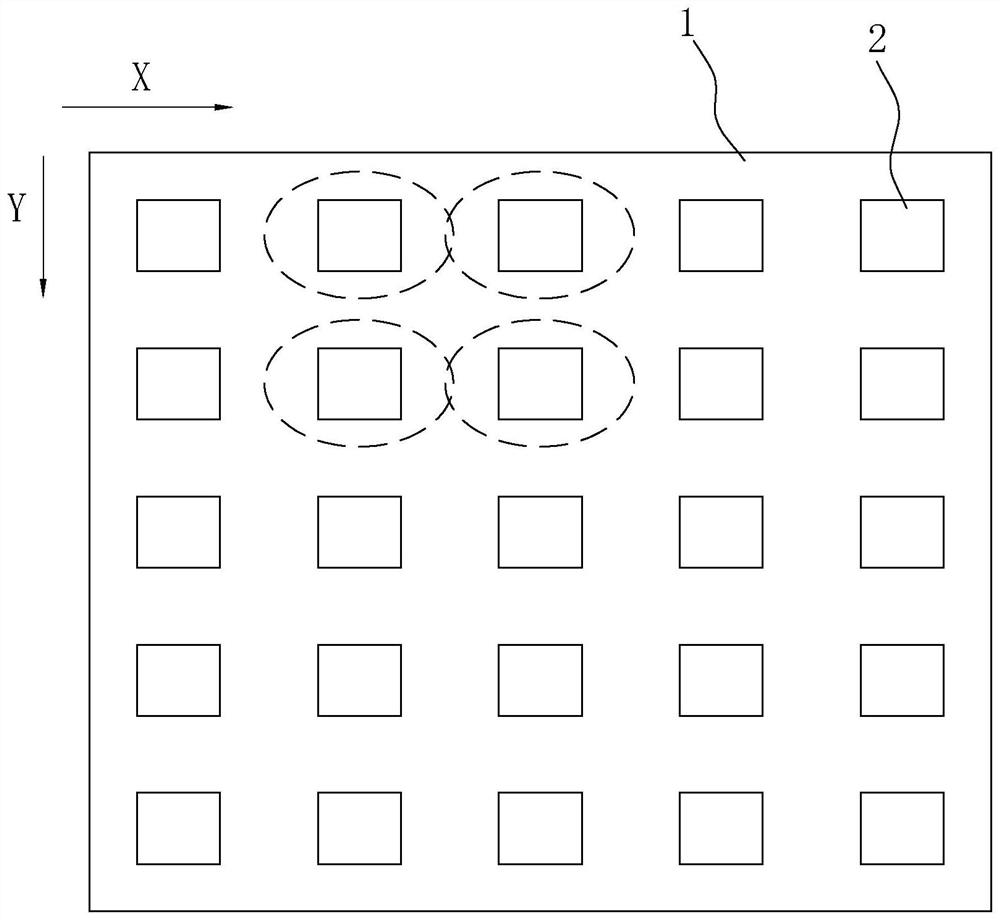

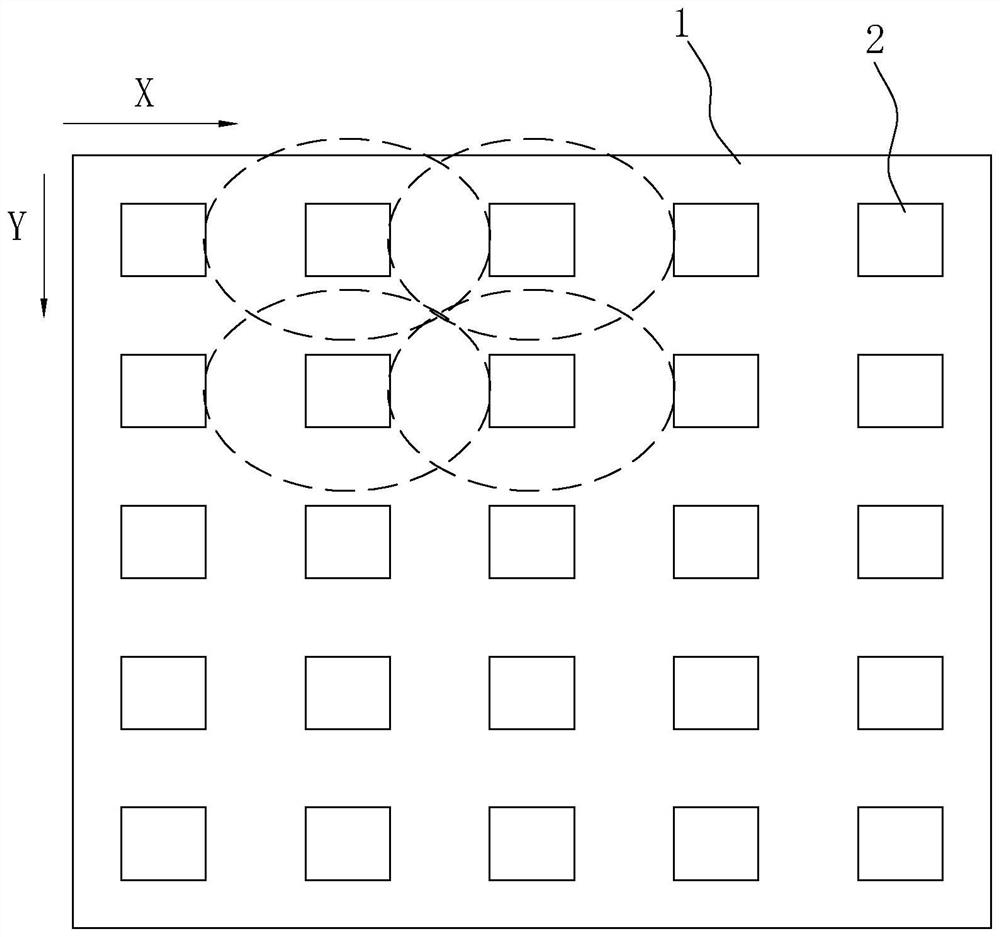

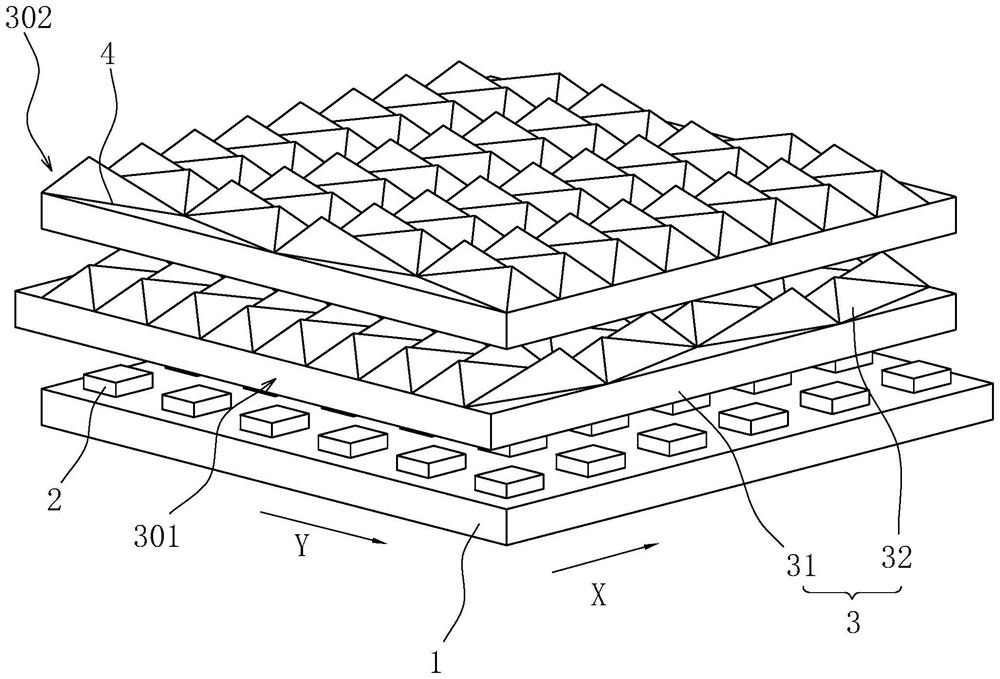

[0045] refer to figure 1 , figure 2 and image 3 , the combined structure of the beam splitter, including a mounting plate 1, a plurality of lamp beads 2 and two beam splitters 3, a plurality of lamp beads 2 are arranged at intervals on the mounting plate 1 in a rectangular array, and two beam splitters 3 are stacked up and down, and set above lamp bead 2. The X direction is parallel to the long axis of the illumination range of the lamp bead 2, and the Y direction is parallel to the short axis of the illumination range of the lamp bead 2. The beam splitter 3 closest to the lamp bead 2 is set within the irradiation range of the lamp bead 2, and diverges the light of the lamp bead 2 along the Y direction. The light diverges in the X direction.

[0046] Since the beam splitter 3 uses its own structure to diverge light, the requirement for the distance between the beam splitter 3 and the lamp bead 2 is relatively small, which can effectively shorten the distance between the ...

Embodiment 2

[0054] refer to Figure 5 The difference between Embodiment 2 and Embodiment 1 is that the beam splitting blocks 32 on the second beam splitting plate 302 are arranged staggered along the X direction, and the waists of the bottom contours 4 of adjacent beam splitting blocks 32 overlap. Arranged linearly along the Y direction, the top corners of the bottom profile 4 are connected to the bottom edge of another bottom profile 4 . With such an arrangement, under the same condition that it can be densely distributed on the bottom plate 31, the arrangement of the light splitters 32 is more uniform, so that the divergence of the lights by the light splitters 32 is more uniform, reducing the difference between light and dark after the lights are atomized, and improving Fog effect on lights.

Embodiment 3

[0056] refer to Figure 6 , The difference between Embodiment 3 and Embodiment 1 is that: the bottom profile 4 of the spectroscopic block 32 is an isosceles obtuse triangle or an isosceles right triangle. In the following, an obtuse-angled isosceles triangle is used for illustration.

[0057] refer to Figure 6 , on the first beam splitting plate 301, the beam splitting blocks 32 are arranged in a staggered manner along the X direction, and the waists of the bottom contours 4 of the adjacent beam splitting blocks 32 overlap, and the beam splitting blocks 32 are linearly arranged along the Y direction, and the adjacent beam splitting blocks 32 The apex angles of the bottom contours 4 are opposite, and the bottom lines of the bottom contours 4 of two adjacent spectroscopic blocks 32 coincide, so that the adjacent bottom contours 4 are spliced into a rhombus.

[0058] Under the same specification, the beam splitter 32 whose bottom profile 4 is an obtuse-angled isosceles trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com