Workshop production line intelligent line side cabinet and storing and taking method thereof

A production line and smart line technology, which is applied to coin-operated equipment, instruments, instrument-controlled coin-operated equipment for distributing discrete items, etc. Inconvenient return, lack of intelligent warehouse management of tools and fixtures, etc., to improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

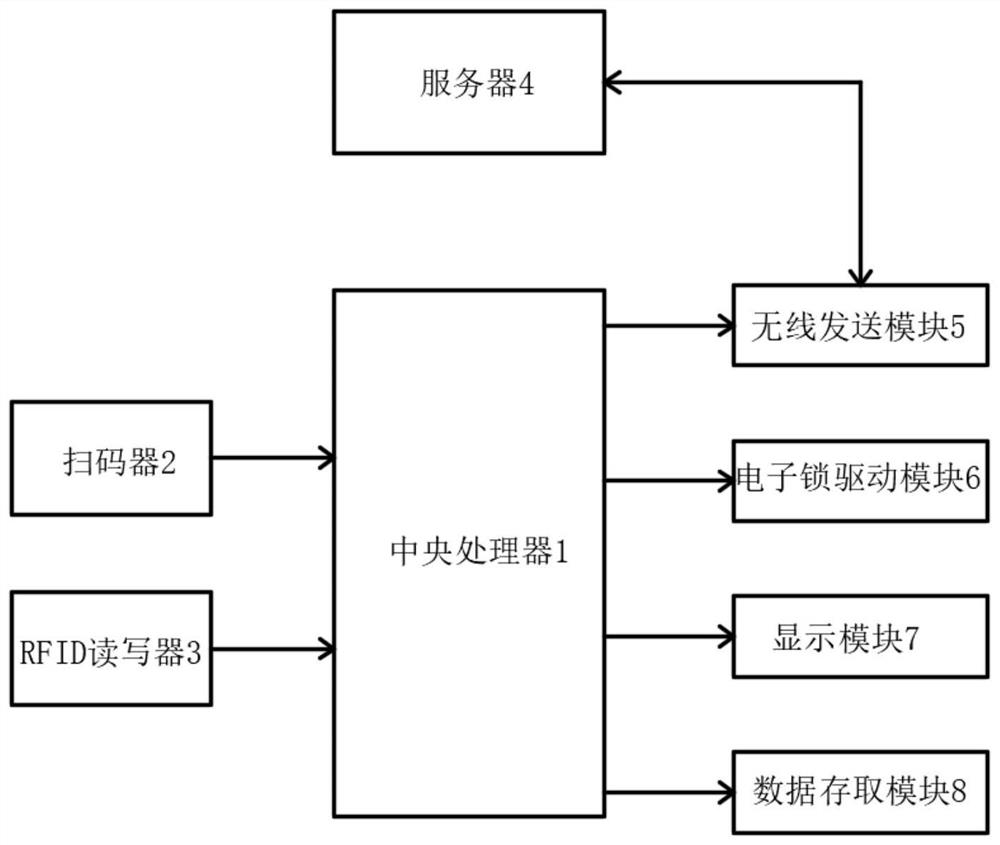

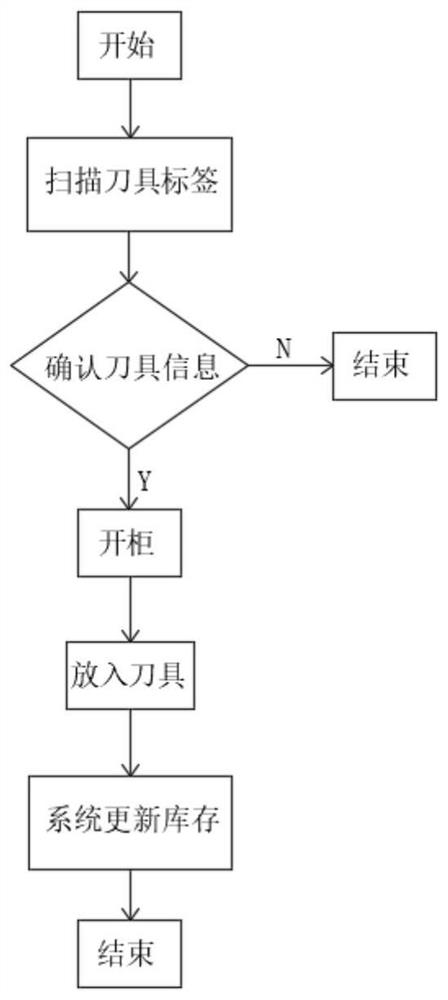

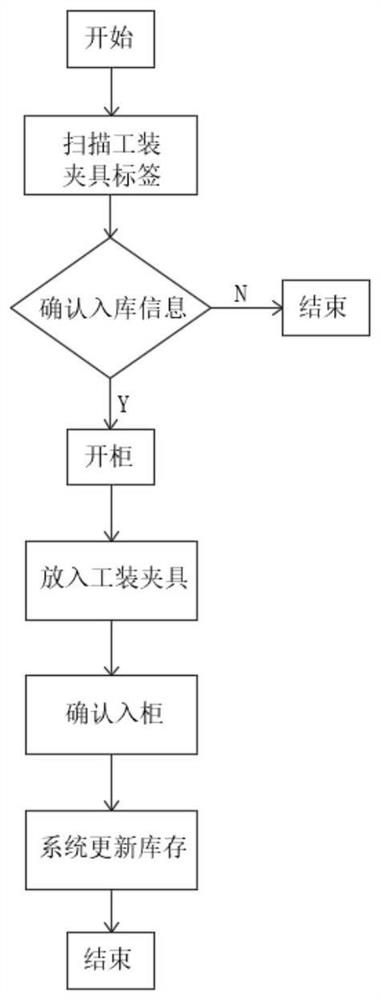

[0028] Such as figure 1 and 10 As shown, the intelligent line side cabinet of the workshop production line includes a main cabinet body 9 and a plurality of auxiliary cabinet bodies 10, as well as RFID electronic tags attached to stored items. The main cabinet body 9 and the auxiliary cabinet body 10 are divided into multiple compartments. The compartments are equipped with cabinet doors and electronic locks for locking the cabinet doors.

[0029] The stored items are knives, tooling fixtures, regulating valve assembly accessories or production materials, and RFID electronic tags are affixed to the tools, tooling fixtures, regulating valve assembly accessories or production materials.

[0030] The intelligent line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com