Semiconductor module

A technology of semiconductors and molded parts, which is applied in the field of semiconductor modules and can solve problems that hinder the miniaturization of mounting substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

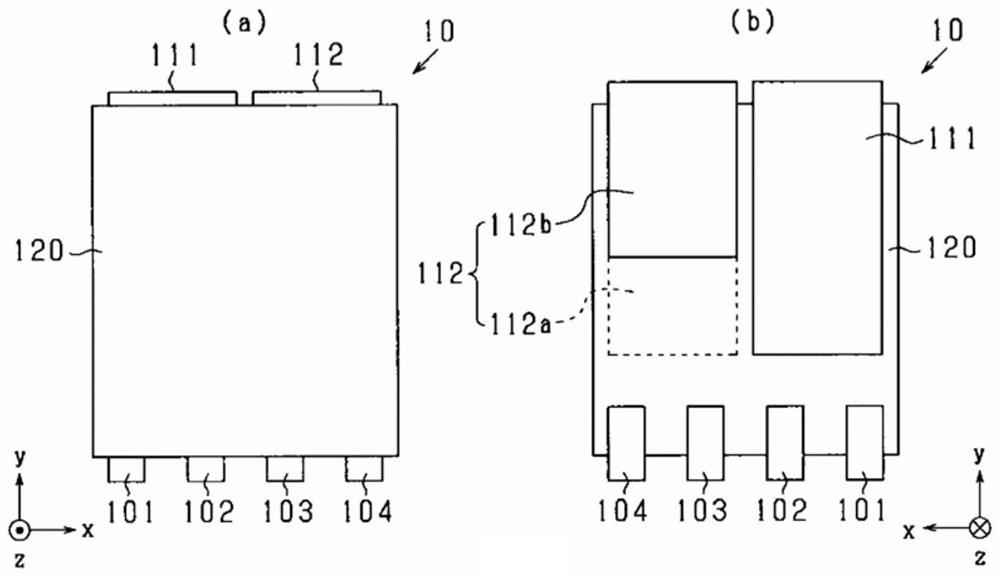

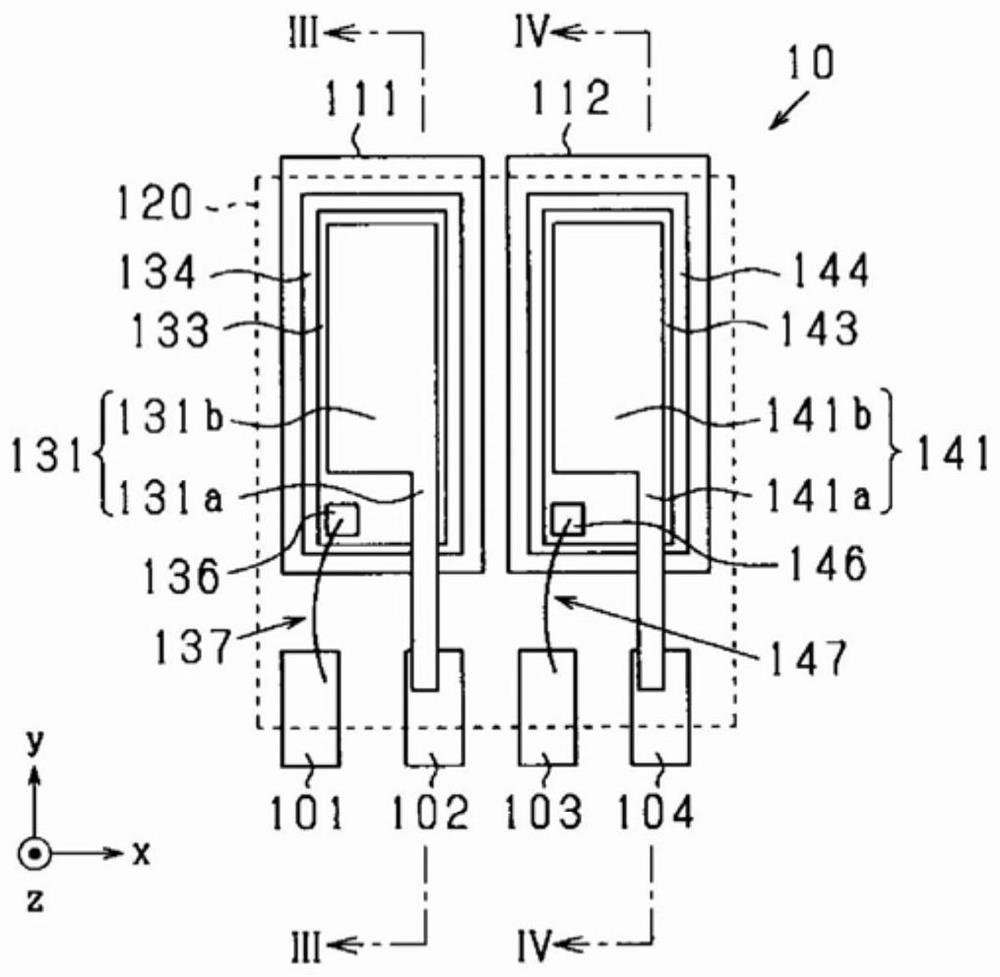

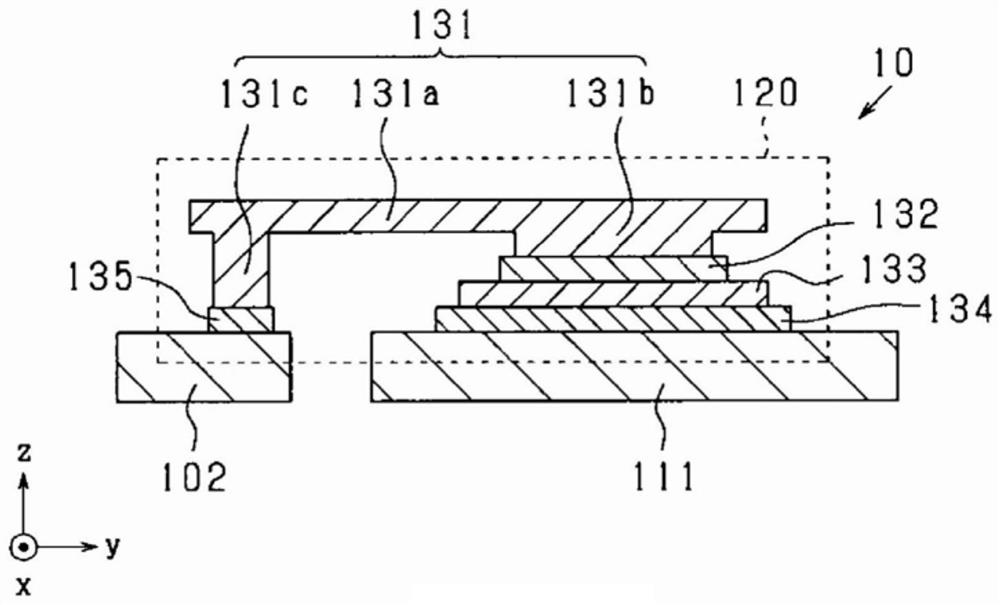

[0058] Such as Figure 1~5 As shown, the semiconductor module 10 according to the first embodiment includes a first semiconductor element 133 and a second semiconductor element 143, a resin mold 120 integrally sealing the first semiconductor element 133 and the second semiconductor element 143, and a conductive member 101. ~ 104, and conductive components 111, 112, 131, 141. Figure 1~5 The shown x-direction and y-direction are the lateral sides of the semiconductor module 10 , the xy plane direction is the planar direction of the semiconductor module 10 . The z direction is an up and down direction perpendicular to the planar direction.

[0059] Such as figure 1 As shown in (a), the semiconductor module 10 has four external terminals protruding in the negative direction of the y-axis and two external terminals protruding in the positive direction of the y-axis from the resin mold 120 having a substantially rectangular shape in plan view. Exterior. The four external termin...

no. 2 approach

[0096] In the first embodiment, a plurality of semiconductor elements (the first semiconductor element 133 and the second semiconductor element 143 ) were exemplified and arranged in the same orientation as the semiconductor elements adjacent to each other in a state substantially parallel to the adjacent semiconductor elements and Although described, like the second embodiment, they may be arranged in a direction opposite to that of the adjacent semiconductor elements so as to be approximately point-symmetrical to the adjacent semiconductor elements.

[0097]In the semiconductor module 20 according to the second embodiment, as Figures 12 to 15 As shown, in the resin mold 220, the second semiconductor element 243 and the first semiconductor element 233 are in an orientation in which the second semiconductor element 243 is rotated by 180° about the vertical direction (z direction) relative to the first semiconductor element 233. They are integrally sealed in a state aligned an...

no. 3 approach

[0112] In the first embodiment and the second embodiment, the conductive members are aligned and arranged in the direction (x direction) perpendicular to the direction (y direction) in which the external terminals protrude for the plurality of semiconductor elements, but they may also be arranged in the direction The directions in which the external terminals protrude are aligned and arranged.

[0113] In the semiconductor module 30 according to the third embodiment, as Figure 20-23 As shown, in the resin molded part 320, the second semiconductor element 343 and the first semiconductor element 333 are in an orientation in which the second semiconductor element 343 is rotated by 180° with respect to the first semiconductor element 333 in the vertical direction (z direction). They are integrally sealed in a state aligned and arranged in the y direction. That is, the first semiconductor element 333 and the second semiconductor element 343 are arranged in opposite directions to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap