Same-plate difference roll shifting feedforward static control method

A technology of static control and roll shifting, which is applied in the direction of overall factory control, rolling mill control devices, manufacturing tools, etc., to achieve the effect of broadening the market prospect and improving the control level of the same plate difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

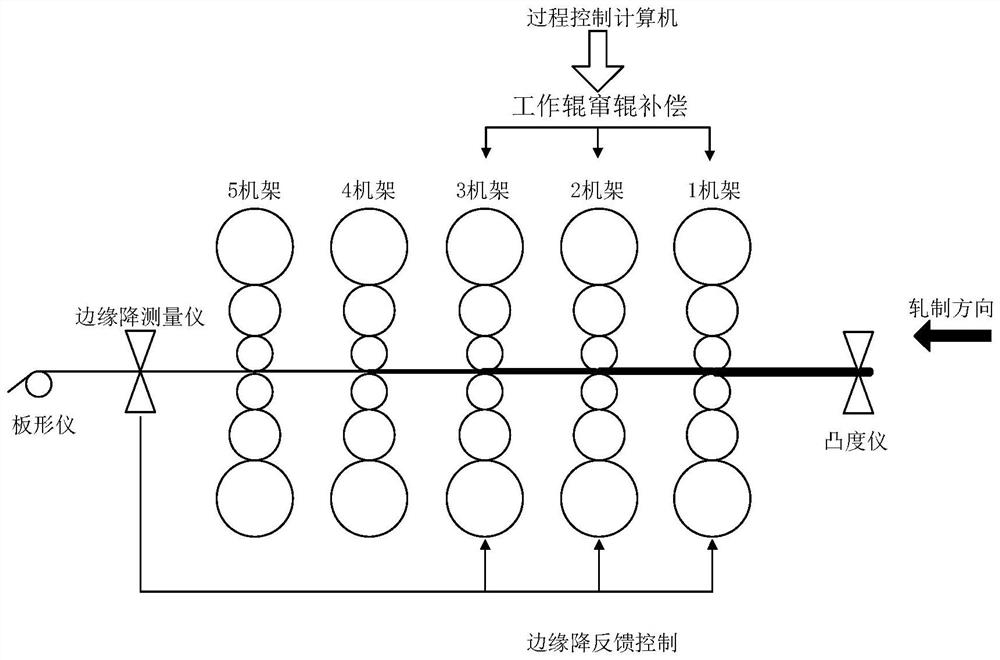

[0042] The present invention will be further described in detail below in conjunction with the embodiments, a feed-forward static control method for differential roll shifting on the same plate, such as figure 1 As shown, a crown meter is installed at the entrance of the continuous rolling mill to detect the crown value of the hot strip incoming material in real time and upload it to the process control computer. The process control computer calculates the axial shift position of the work roll, and the calculated value Accumulated with L2 roll shifting set value, output to L1 for 1#-3# frame work roll shifting setting; the basic automation system is referred to as L1, and the process control system is referred to as L2.

[0043] Taking a five-stand tandem cold rolling mill, the set value of the center point of the hot-rolled incoming material thickness is 2614 μm, the set value of the cold-rolled exit thickness is 500 μm, and the difference between the exit and the plate is req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com