High-capacity charging tray device for horizontal ball polishing machine and feeding method

A light ball machine and large-capacity technology, which is applied in the field of mechanical processing, can solve the problem of not being able to meet the demand for steel ball feeding of the light ball machine, and can not simultaneously realize a single batch of steel ball feeding. The number of steel balls entering the light ball machine is equal In order to achieve the effect of reducing the number of hoisting and loading and unloading time, reducing the probability of mixing balls, and improving stability control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

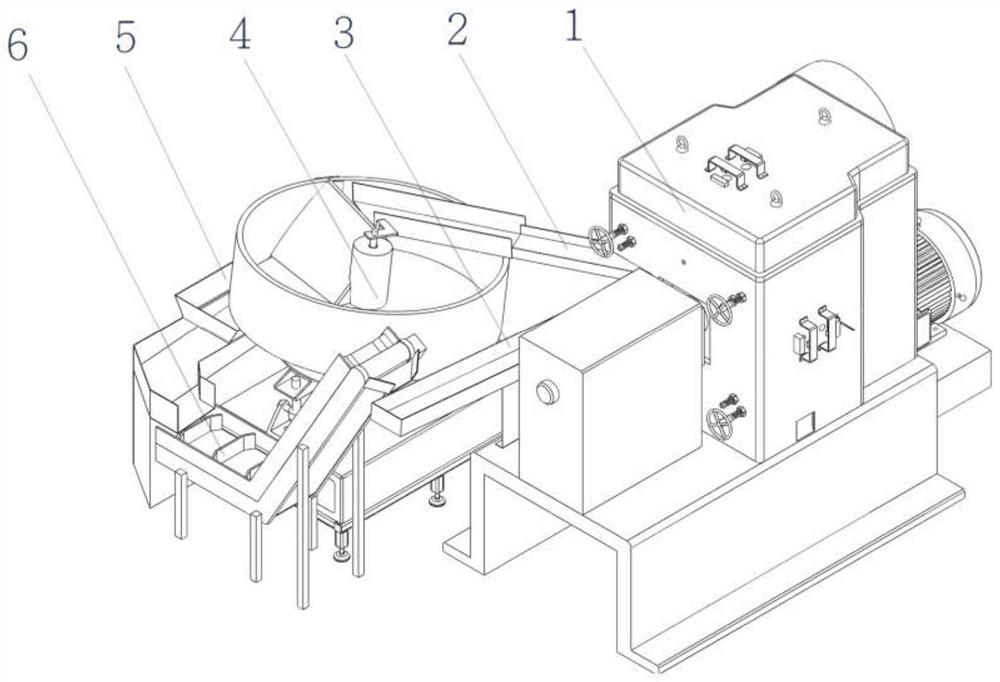

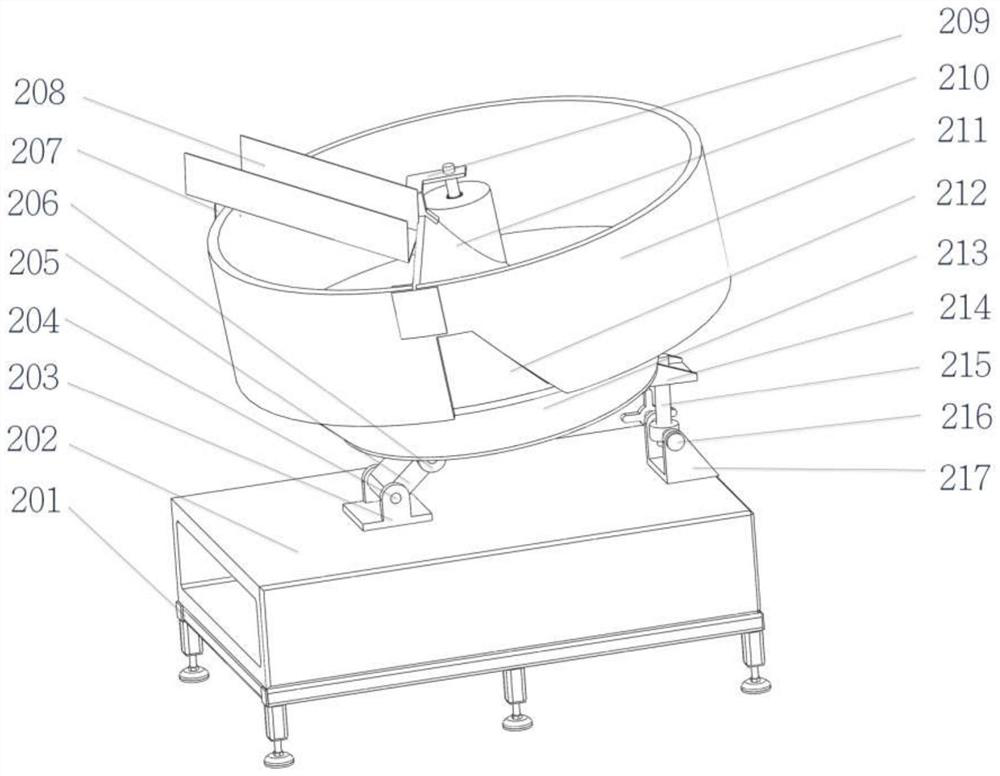

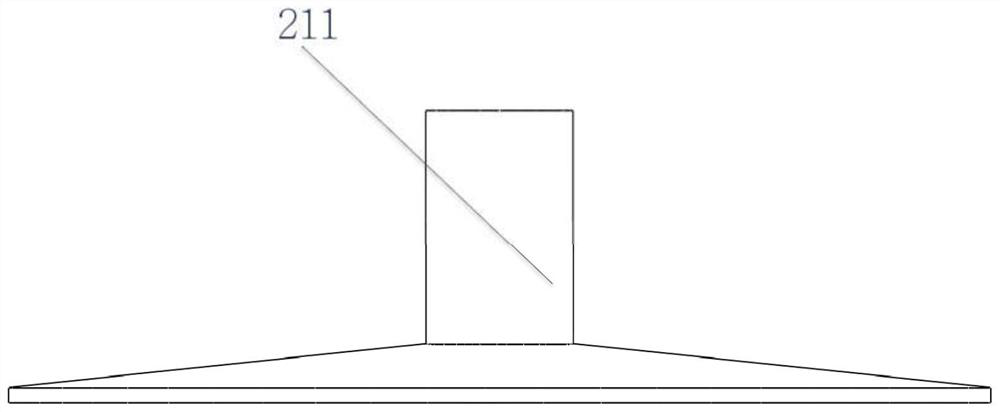

[0051] Such as Figures 1 to 4As shown, the present invention provides a large-capacity material tray device and a feeding method for a horizontal photosphere machine, including: a photosphere machine 1, a feeding mechanism 2, a transmission mechanism 5, a lifting mechanism 6 and a feeding mechanism 3. The optical ball machine 1 is suitable for grinding steel balls, and one side of the optical ball machine 1 is provided with an unloading mechanism 2 , and the unloading mechanism 2 communicates with the inner cavity of the optical ball machine 1 . The unloading mechanism 2 is arranged obliquely downward along the direction away from the photosphere camera 1 . One side of the unloading mechanism 2 is provided with an opening, and a conveying mechanism 5 is provided below the opening. The size of the opening is larger than the size of the steel ball. The steel balls after being ground by the optical ball machine 1 can enter the unloading mechanism 2 and rotate counterclockwise...

Embodiment 2

[0067] On the basis of Embodiment 1, this Embodiment 2 also provides a method for loading a large-capacity tray device for a horizontal photosphere machine, including a method for horizontal photosphere machines shown in Embodiment 1. The large-capacity material tray device of machine 1, a specific feeding method for the large-capacity material tray device of the horizontal photosphere machine is as follows:

[0068] S1: The steel balls ground in the light ball machine 1 are transmitted outwards through the first-flow ball lane 208, and the steel balls roll into the material delivery tray 212 along the slope on one side of the ball retaining plate 210;

[0069] S2: Drive the steel ball to rotate counterclockwise to the side of the opening through the feeding tray 212, and under the obstruction of the ball blocking plate 210, the steel ball rolls down from the opening;

[0070] S3: Through the second flow ball path 302, the steel ball is rolled into the lifting mechanism 6 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com