Copper strip packaging tool

A packaging and tooling technology, applied in the field of copper tape production equipment, can solve the problems of loose wrapping of the tape, damage at the corners of the copper tape, and excessive length of the tape, so as to reduce damage and rupture, increase wrapping and tightening. Sealing, excellent packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] The specific implementation of the present invention will be described in detail below in conjunction with specific embodiments.

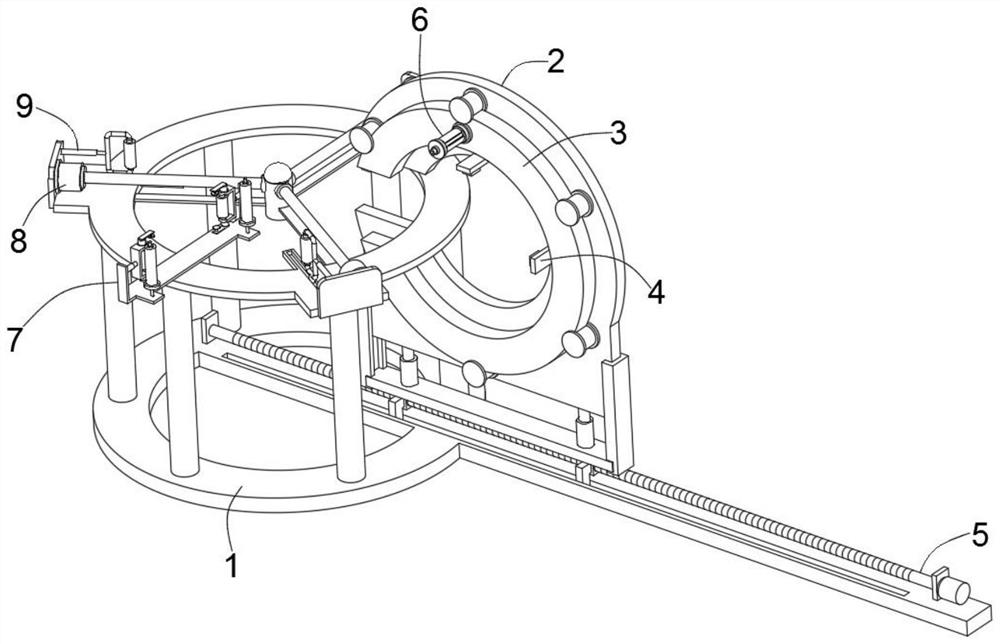

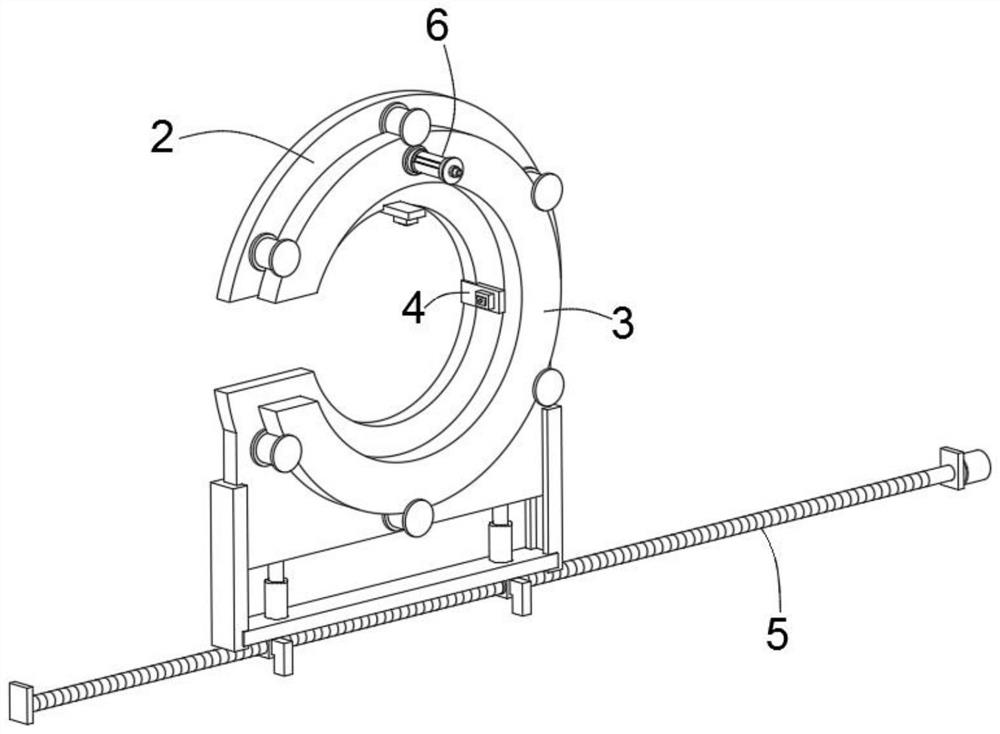

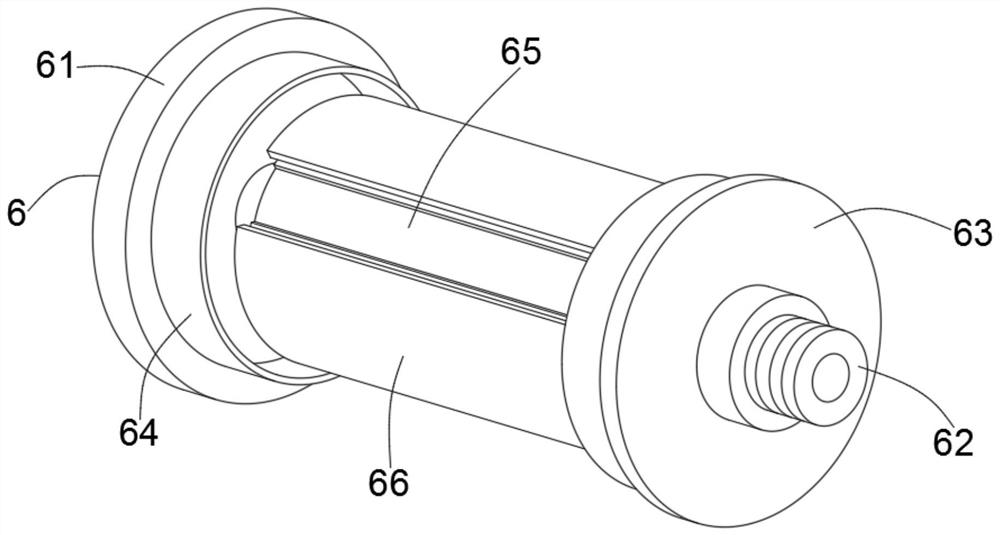

[0036] see Figure 1 to Figure 9 , a copper tape packaging tool provided by an embodiment of the present invention, the copper tape packaging tool includes: a frame 1, an extrusion assembly 6, an adjustment assembly 5 and an auxiliary assembly 7, and the outer wall of the frame 1 is provided with a mounting frame 2. On the outer wall of the installation frame 2, a rotating ring 3 connected by rotation is mounted on the drive wheel 2a

[0037] It should be noted t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap