Testing tool for improving outgoing quality inspection and spot check efficiency of products

A technology for testing tooling and efficiency, applied in the field of service robots, can solve the problems of long design cycle, inflexible design, and large resource occupation, and achieve the effect of saving area, saving sampling inspection man-hours, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

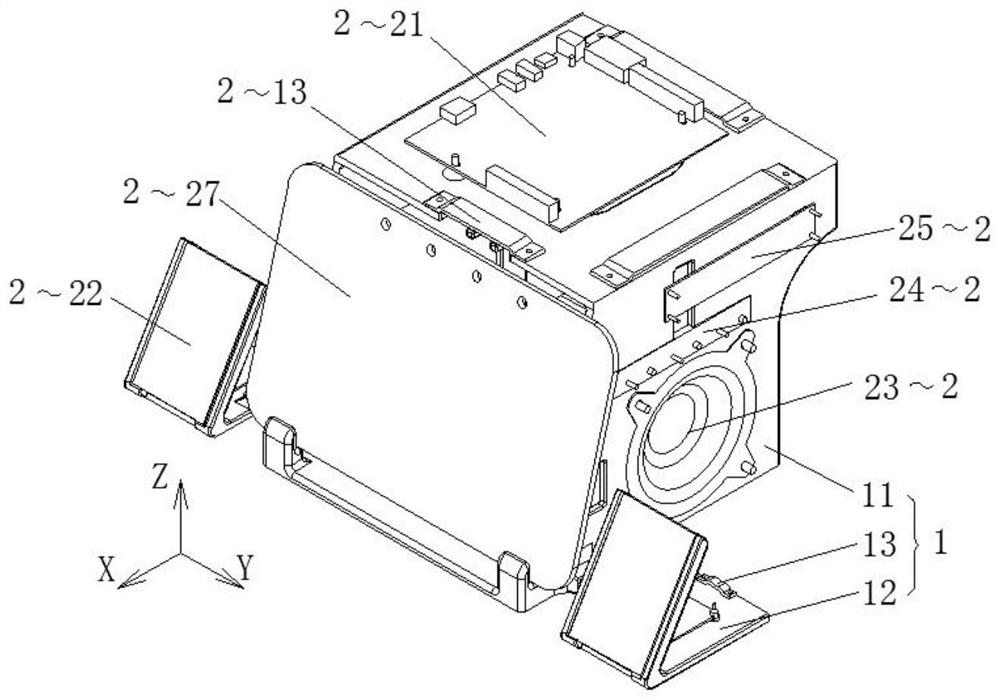

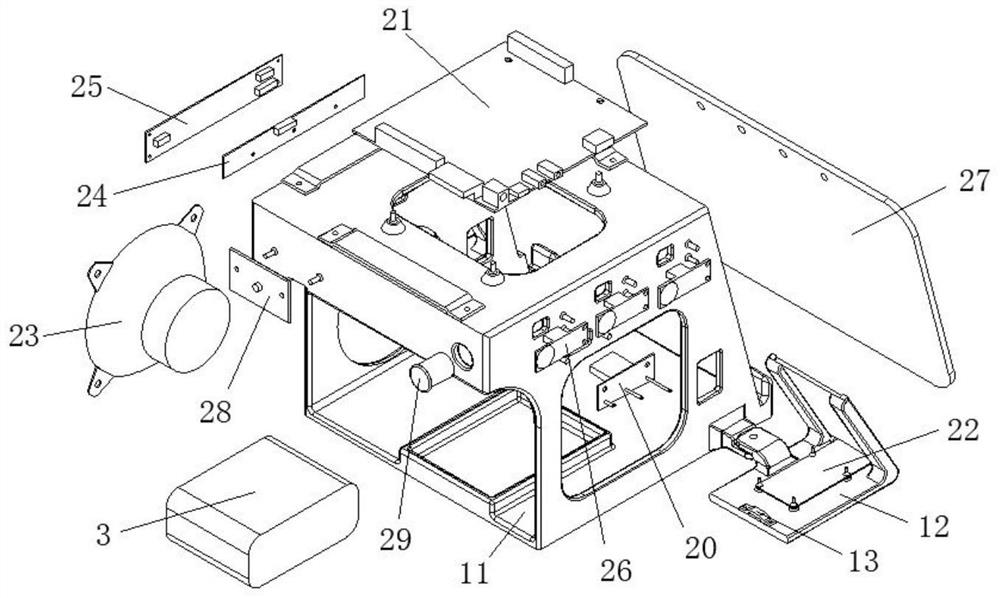

[0053] As another embodiment of the present invention, the structure of the test tool used to improve the efficiency of product quality inspection and random inspection is basically the same as the structure in the above-mentioned embodiment, and the difference lies in that the support assembly 1 includes a center base 11, The bracket 12 and the limit pressure plate 13, wherein the center base 11 is connected to the test component 2 for installing and supporting the test component 2, the control system module 21 is arranged on the top of the center base 11, and the power supply component 3 is arranged at the bottom of the center base 11 The bracket 12 is connected in rotation with the central base 11, and the bracket 12 is provided with two groups, which are respectively arranged on both sides of the central base 11. The two brackets 12 are symmetrically arranged, and the placement of the bracket 12 relative to the central base 11 can be adjusted by means of rotational connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com