Full-automatic magnetic sheet inserting machine

A fully automatic, magnetic chip technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low efficiency and high labor cost, and achieve the effect of reducing labor cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

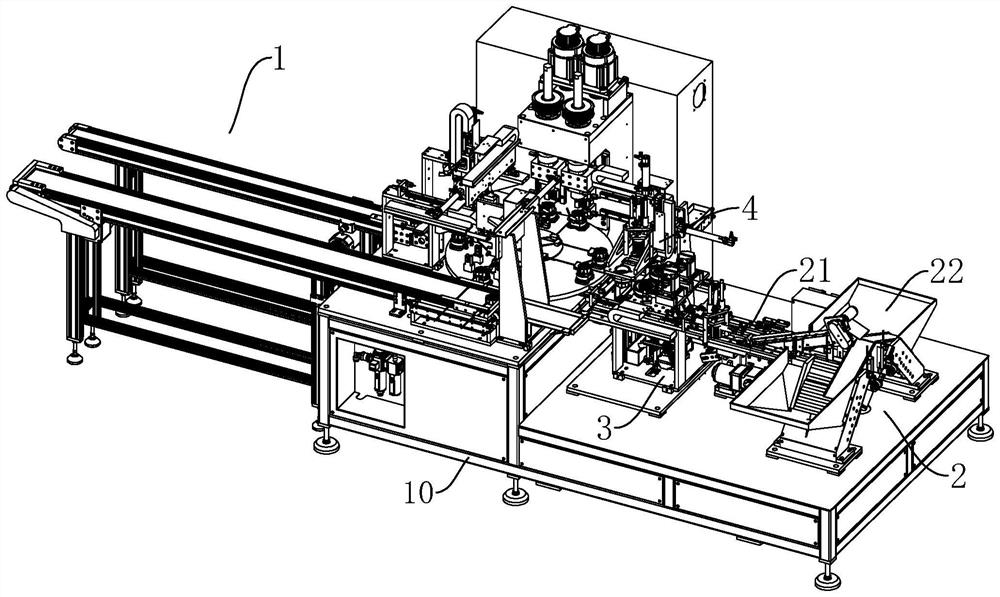

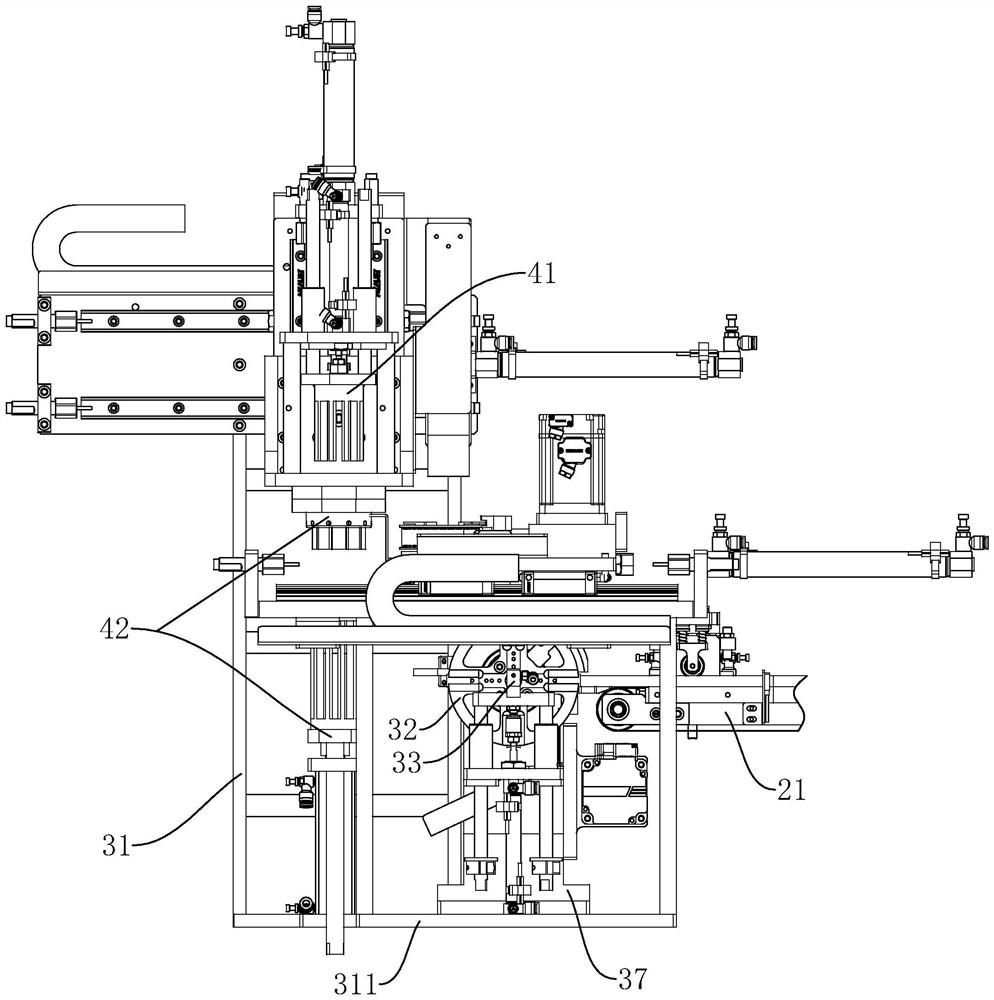

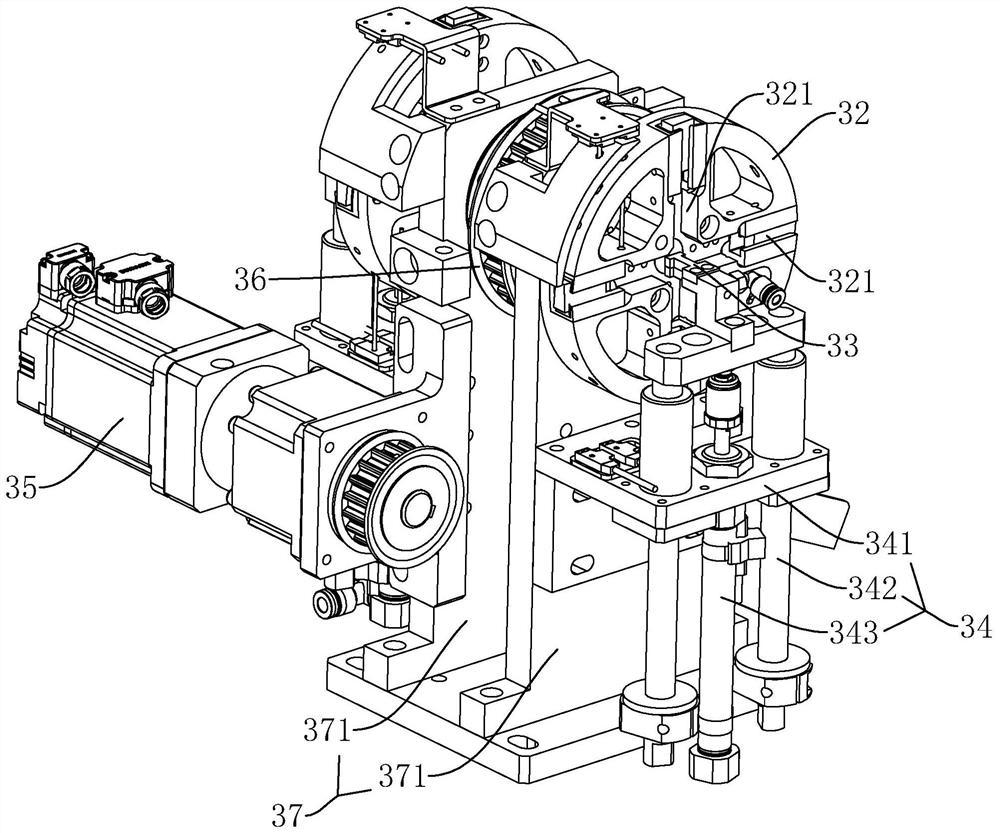

[0026] combine Figure 1 to Figure 8 A further description will be given to the fully automatic disk inserting machine of the present invention.

[0027] A fully automatic disk inserting machine, characterized in that it includes a frame body 10 and iron core loading and unloading devices 1 and magnetic sheet feeding devices 2 installed on the left and right sides of the frame body 10, and the magnetic chip storage device installed on the frame body Device 3 , a device 4 for dumping and pressing the disks.

[0028] The magnetic sheet feeding device 2 includes a feeding belt 21 and a feeding mechanism for feeding the feeding belt 21 . There are guide rails extending along the conveying direction of the feed belt 21 on both sides of the feed belt 21, so that the magnetic sheet is moved along a desired track under the guidance of the guide rails. The feeding mechanism includes a hopper 22 for putting the magnetic sheet into, a push plate that is slidably arranged on the side wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap