Concrete pouring device for building construction

A watering device and construction technology, which is applied in the direction of clay preparation device, unloading device, cement mixing device, etc., can solve problems such as the blockage of the discharge port, and achieve the effect of convenient falling, convenient moving, and convenient hand-held watering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

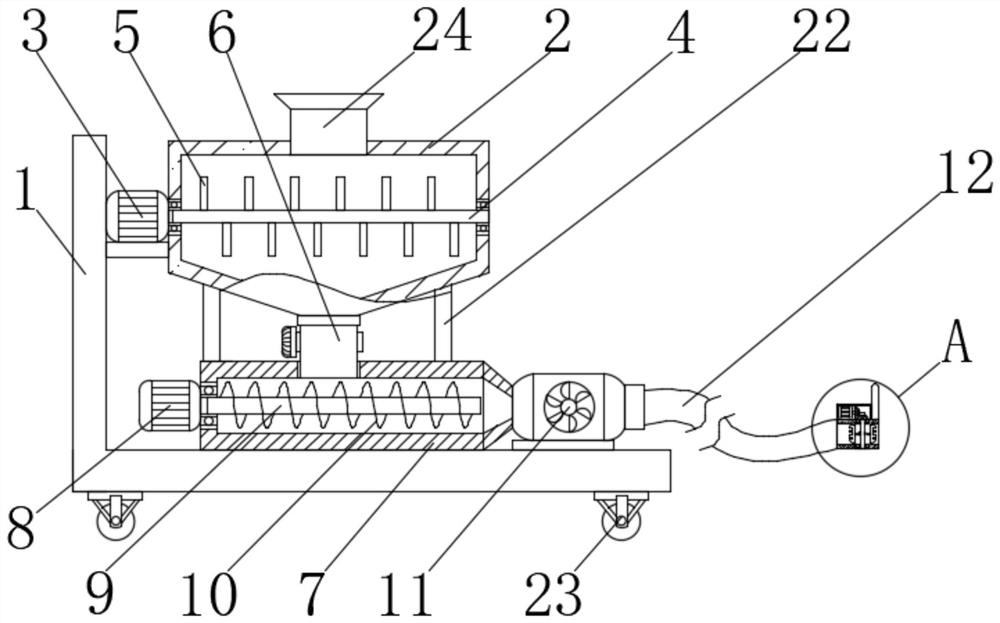

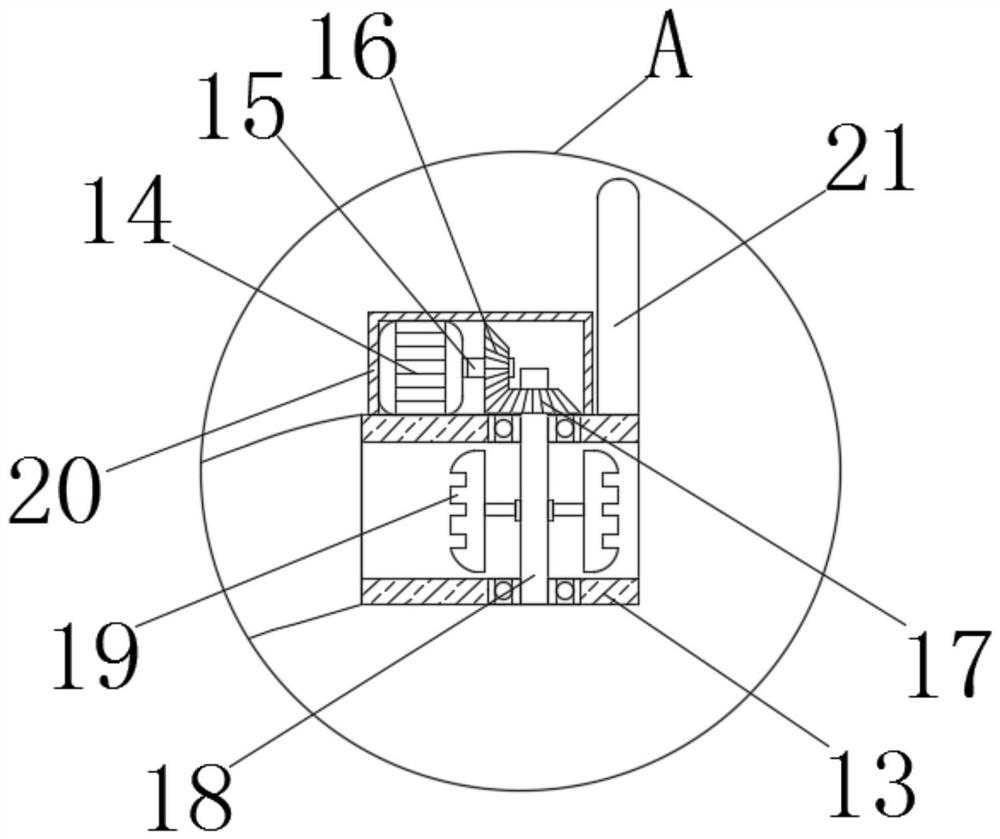

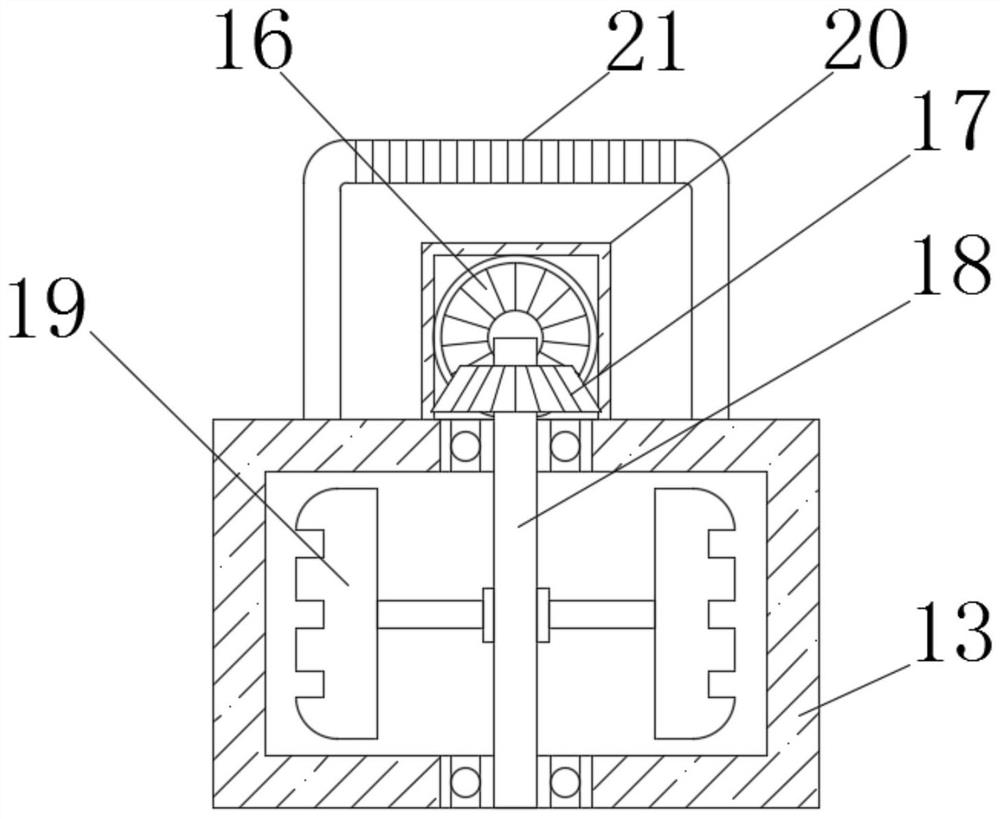

[0024] see Figure 1-4 , a concrete pouring device for building construction, comprising an L-shaped base 1, the left side of the inner cavity of the L-shaped base 1 is fixedly connected with a mixing box 2 through a bracket, the left side of the mixing box 2 is fixedly connected with a first motor 3, and the first motor The output end of 3 is welded with a stirring rod 4, the right side of the stirring rod 4 runs through the stirring box 2 and extends to the inner cavity of the stirring box 2 through bearing rotation connection, the surface of the stirring rod 4 is welded with the stirring blade 5, the stirring box 2 The bottom is connected with a discharge pipe 6, and the bottom of the discharge pipe 6 is connected with a push tube 7. The bottom of the push tube 7 is fixedly connected with the top of the inner cavity of the L-shaped base 1, and the left side of the push tube 7 is fixedly connected with the second The motor 8 and the output end of the second motor 8 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com