Carbon fiber sound insulation box assembly

A carbon fiber and sound insulation technology, which is applied in the direction of housing, machine/engine, mechanical equipment, etc., can solve the problems that the sound insulation box is difficult to meet the weight requirements, and the total weight of the sound insulation box is limited, so as to achieve light weight and good performance. High sealing performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

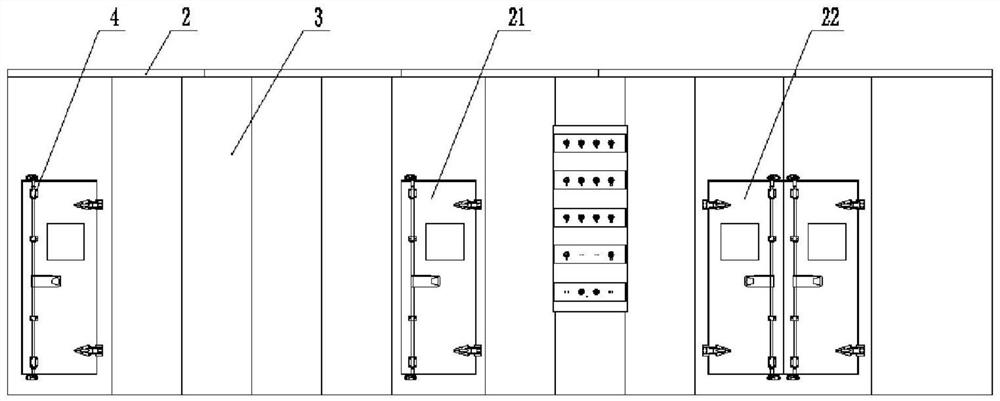

[0026] Such as figure 1 , Figure 4 with Figure 5 As shown, the present invention provides a carbon fiber sound insulation box body, comprising a main frame 1 with a rectangular parallelepiped structure as a whole, a top wall plate 2 installed on the top of the main frame 1, a side wall plate 3 installed on the side of the main frame, and a sound insulation door 4 Installed on the side wall panel 3. The top wall plate 2 and the side wall plate 3 are fixed on the main frame 1 by self-tapping screws.

Embodiment 2

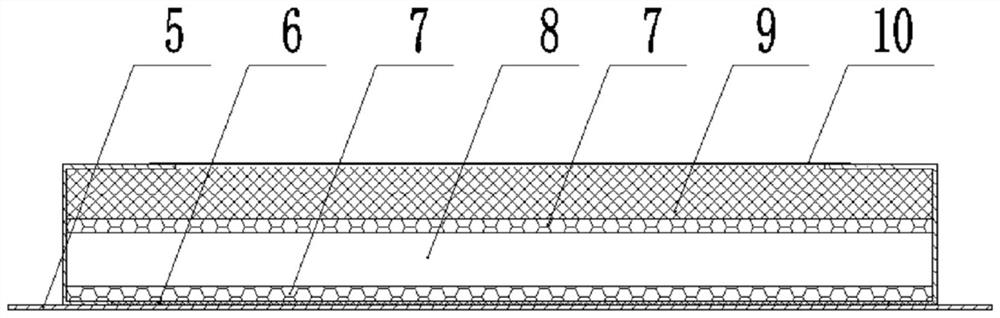

[0028] On the basis of the box-packed body structure provided in Embodiment 1, the top wall plate 2 and the side wall plate 3 of this embodiment use carbon fiber plates as the outer walls. Compared with the metal steel plate, the carbon fiber plate of the same thickness is 8-10dB lower than the metal steel plate in the frequency range of 300-700Hz; in the frequency range of 700-4000Hz, the carbon fiber plate is 3-5dB lower than the metal steel plate, so To achieve the high sound insulation performance of carbon fiber panels, a combined carbon fiber sound insulation layer is required. Such as figure 2 As shown, the combined carbon fiber sound insulation layer includes 4mm thick carbon fiber outer plate 5, 3mm thick sound insulation felt 6, 10mm thick melamine plate 7, 34mm thick cavity 8, 10mm thick melamine plate 7, 40mm thick glass wool 9 and 1mm thick Perforated plate 10. Each layer of material is laid in order, and polyurethane glue is injected into the joints of the blo...

Embodiment 3

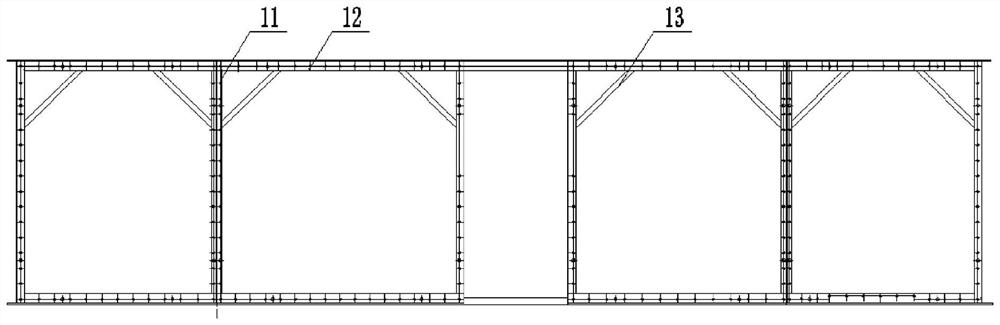

[0030] Such as image 3 As shown, the main frame 1 includes upright columns 11 , top beams 12 and oblique tendons 13 . The column 11, the top cross beam 12 and the diagonal tie bars 13 all adopt carbon fiber structural beams with an H-shaped cross section, and the column 11, the top cross beam 12 and the diagonal tie bars 13 are fixed by bolts. The structural beam made of carbon fiber has high specific strength, and its tensile strength can reach more than 5 times that of the steel structural beam of the same specification. The carbon fiber structural beam is processed in the quasi-isotropic laying direction, which can make the overall strength of the box body high and durable. Shock, can adapt to more severe environment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap