Planetary gear reduction gearbox with self-control lubrication effect

A planetary gear deceleration and autonomous control technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of lack of sound insulation structure, noise can not be weakened, etc., to facilitate normal transmission, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

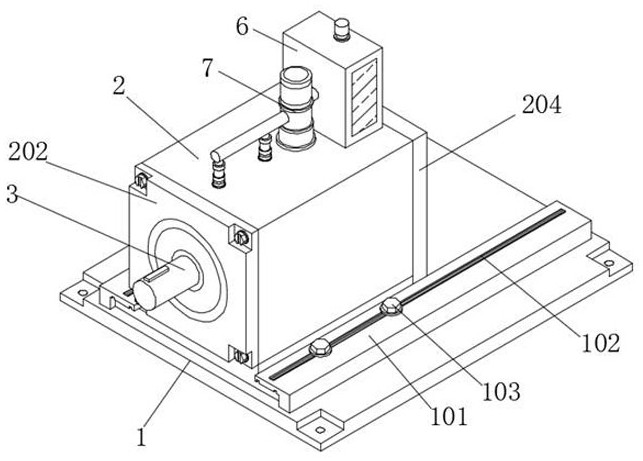

[0042] Embodiment 1, a planetary gear reduction box with self-controlled lubrication effect, including a base 1 and a casing 2, two sets of symmetrically arranged limiting clamps 101 are installed on the top of the base 1, and the two sets of limiting clamps 101 Fitted on the top of both sides of the support plate 206, the top inner wall of the limit clamp 101 and the limit clamp 207 are mutually fitted, and the top of the limit clamp 101 is provided with a through groove 102, and the through groove 102 Tightening screws 103 are installed on the inner thread, and the tightening screws 103 are connected to the inner side of the support plate 206 by threads. The top of the base 1 is movably equipped with a support plate 206, and the top of the support plate 206 is equipped with two groups of symmetrically distributed The limit clip 207 is used to fix the base 1 at a designated position through bolts, which is convenient for workers to fix the device. The worker fits the support p...

Embodiment 2

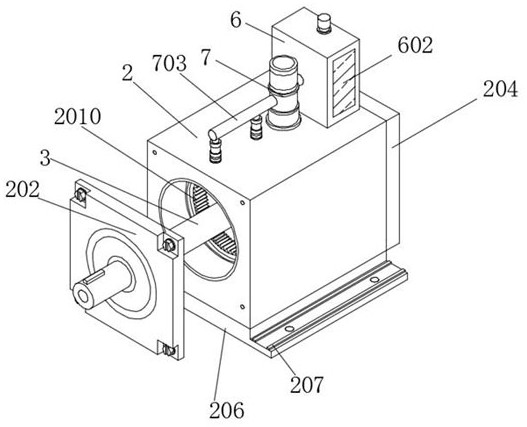

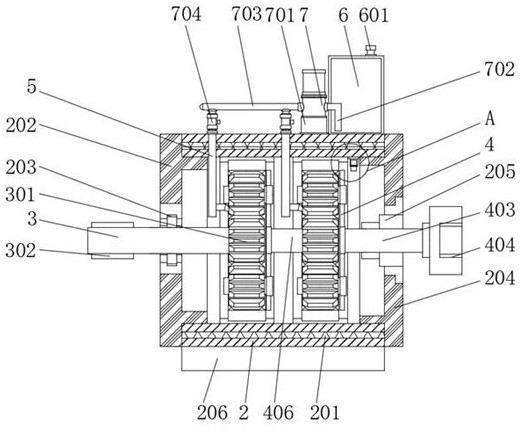

[0044] The second embodiment includes a base 1 and a shell 2, the top of which is equipped with a shell 2, and the shell 2 is located between two sets of limit clips 207, and a sound insulation layer 201 is installed inside the shell 2, and the shell 2 Two sets of inner gear rings 2010 are installed on the inner wall, and the inner gear rings 2010 are located in front of the controller 208. A controller 208 is installed on the top of the inner wall of the housing 2, and a sound sensor 209 is installed at the bottom of the controller 208. The gear rings 2010 in the group are respectively located in front of the corresponding two groups of oil delivery pipes 5, the support plate 206 fixes the top shell 2 to ensure the stability of the shell 2, the shell 2 is fixed to the inner sound insulation layer 201, and the sound insulation layer 201 is installed on the device The outer side of the gear, thereby reducing the transmission of noise, will produce sound in the process of mutual ...

Embodiment 3

[0046] The third embodiment includes a base 1 and a housing 2, the front end of the housing 2 is equipped with a front closure cover 202 through bolts, the inside of the front closure cover 202 is equipped with a first bearing ring 203, and the inside of the first bearing ring 203 is movable An output transmission rod 3 is installed, the front end of the output transmission rod 3 is equipped with a transmission clip 302, the rear end of the output transmission rod 3 is equipped with a first sun gear 301, and the rear end of the housing 2 is installed with a Rear closing cover 204, the inner side of described rear closing cover 204 is installed with second bearing ring 205, and the inner side of described second bearing ring 205 is movably installed with rotating rod 403, and the front end of described rotating rod 403 is installed with first planet carrier 4. The rear end of the rotating rod 403 is equipped with a motor connection port 404, and the front of the first planet car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com