PE water supply pipe

A technology for water supply pipes and hoses, applied in the field of pipe manufacturing, can solve the problems of physical power consumption, unfavorable use, small footprint, etc., and achieve the effects of physical strength saving, rapid laying, and reduction of impact pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

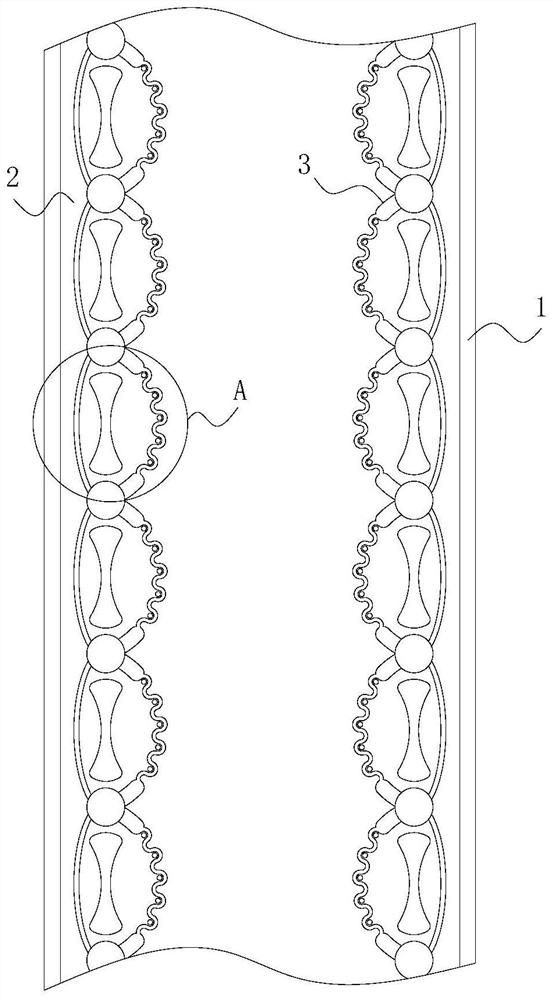

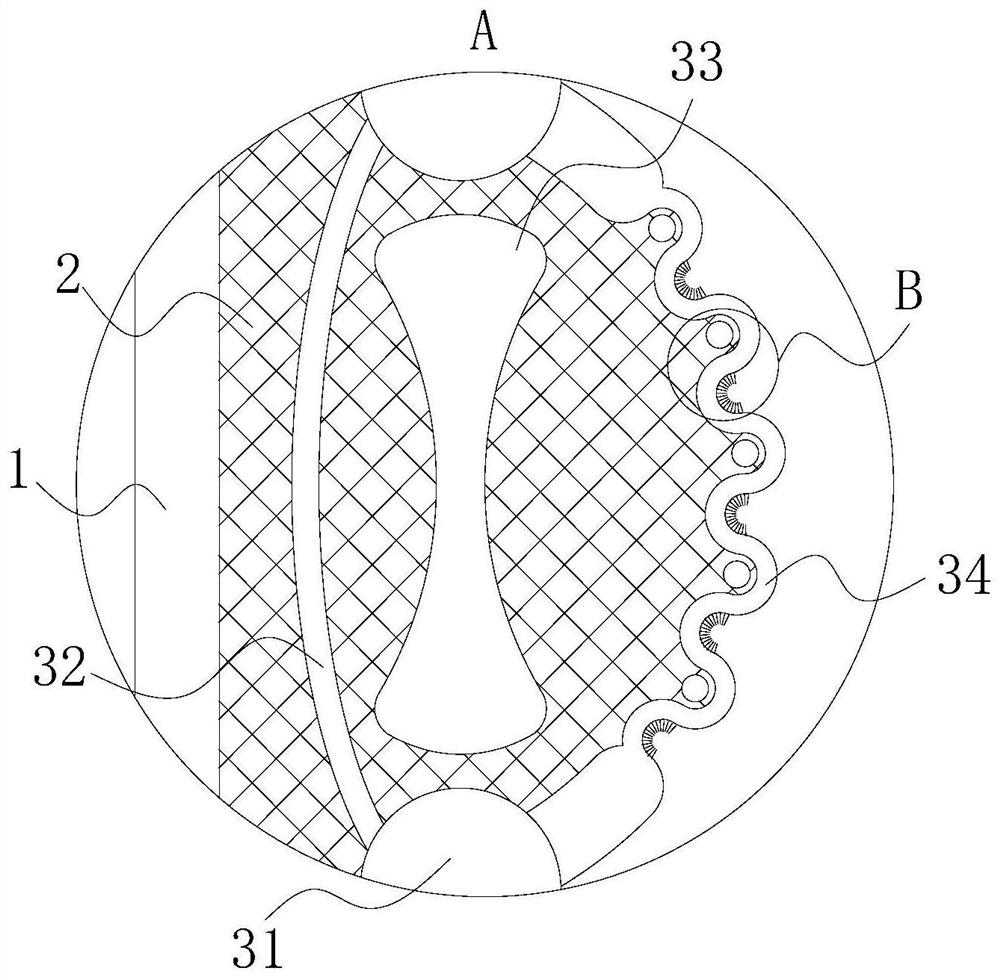

[0018] use Figure 1-Figure 4 A PE water supply pipe according to an embodiment of the present invention is described as follows.

[0019] Such as Figure 1-Figure 4 As shown, a PE water supply pipe according to the present invention includes a main body 1, a PE pipe 2 and a protection mechanism 3; the main body 1 is composed of a normal hose, and the inner surface of the main body 1 is fixedly sleeved with a PE pipe 2, The main body 1 is stored in a winding roller; the inside of the PE pipe 2 is provided with a protection mechanism 3; the protection mechanism 3 includes a mounting ring 31, an elastic ring 32, a special-shaped groove 33, a corrugated ring 34, a vibration chamber 35 and Bristles 36; the mounting rings 31 are inlaid and fixedly installed in the wall of the PE pipe 2 at fixed intervals, and the mounting rings 31 are connected by elastic rings 32; the two ends of the elastic rings 32 are fixedly connected to the mounting rings 31 On the outer surface, the elasti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap