Method for multi-software joint simulation and design of hot-pressing light guide plate lattice points and application thereof

A light guide plate network point and co-simulation technology, applied in the field of backlight, can solve problems such as reducing research and development time, achieve the effects of shortening the development cycle, accurate results, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The light guide plate used in this embodiment is a side-type 21.5-inch backlight, which is composed of a light source, a light guide plate, a reflection film, a diffusion film and a prism film. Among them, the size of the light guide plate is 478×278×2.0mm; the material is PMMA; the refractive index is 1.49; the light source is an LED light strip, which is arranged at equal intervals with 46 LEDs, the output angle is 120°, and the luminous flux of each LED is 22LM.

[0038] A method for multi-software co-simulation and design of dots of a heat-pressed light guide plate, comprising the following steps:

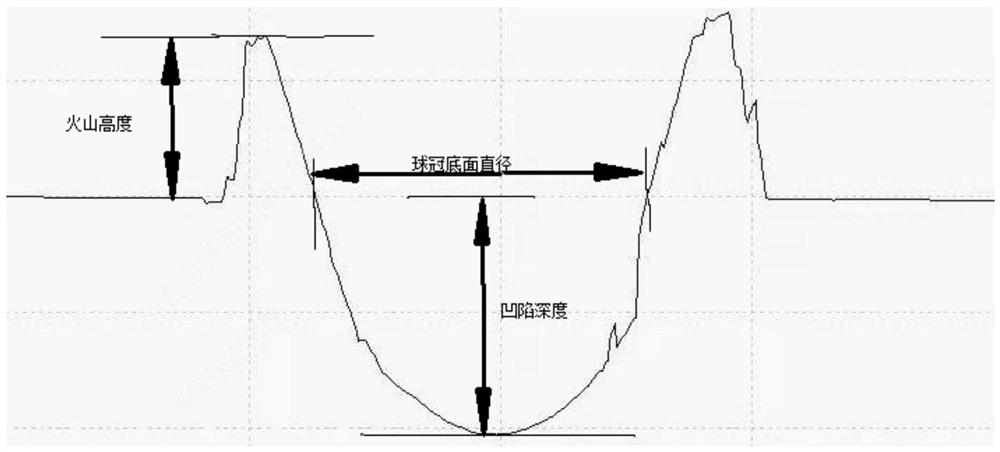

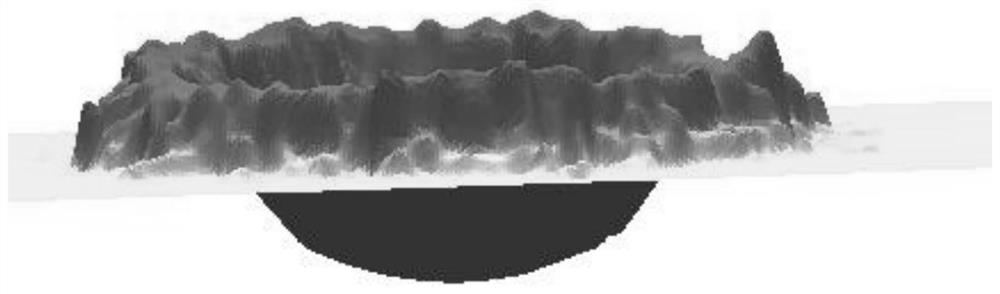

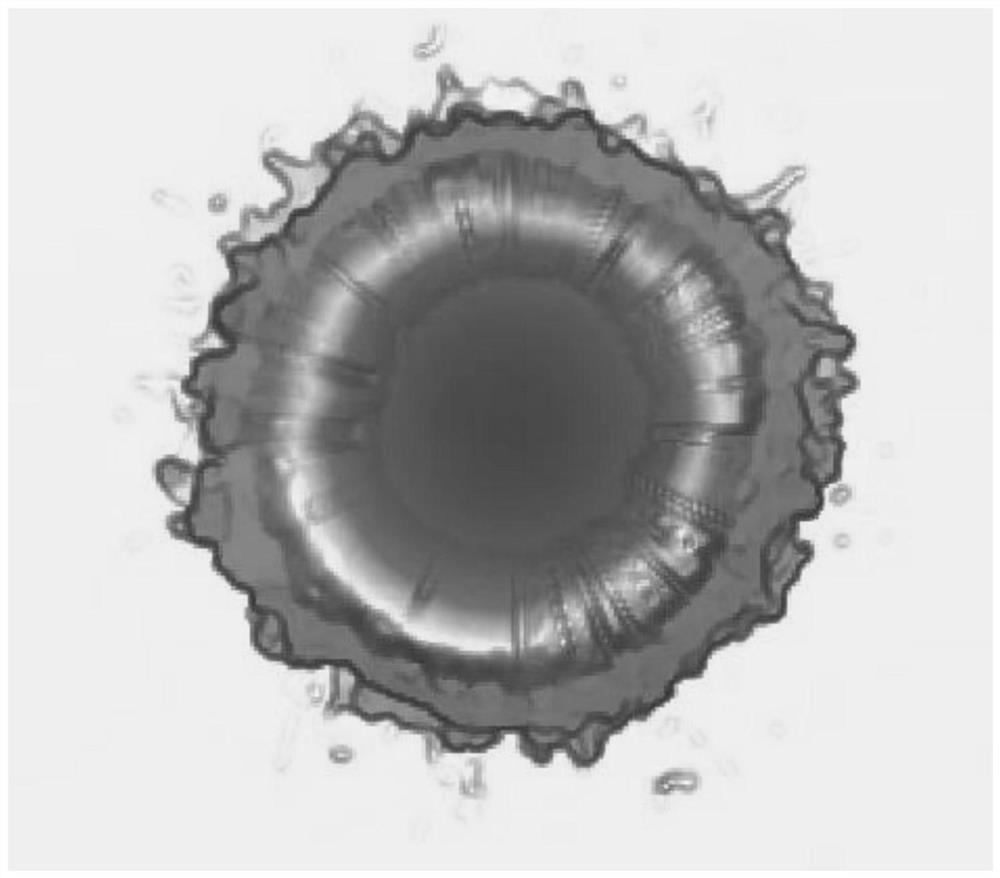

[0039] S1. Process the microstructure, use shooting software to measure the microstructure, and measure the parameters of the crater network;

[0040] S2. Adopt data processing software to process the crater outlet parameter measured in step S1;

[0041] S3. Use 3D software for 3D modeling, and perform Boolean cutting on the crater network parameters after smoothing and...

Embodiment 2

[0053] In addition, the present invention also provides the application of a multi-software co-simulation and method for designing hot-pressed light guide plate dots in the technical field of liquid crystal display and lighting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com