Distributed microstructure sensor network based on time division wavelength division multiplexing and its application method

A technology of time division wavelength division multiplexing and sensor network, which is applied in the direction of time division optical multiplexing system and the use of optical devices to transmit sensing components, etc., which can solve the problem that the system performance has not been greatly improved, and the lack of wavelength division frequency division multiplexing mining , the limited number of multiplexed gratings, etc., to reduce operating and management costs, improve reusability and spatial recognizability, and increase the demodulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

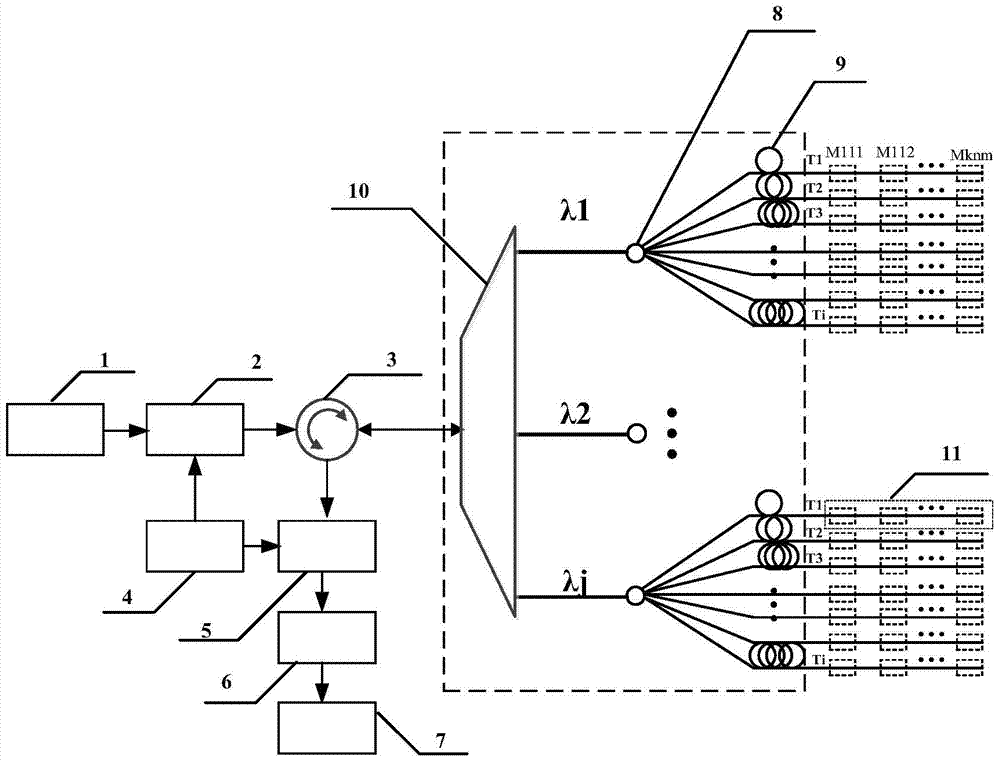

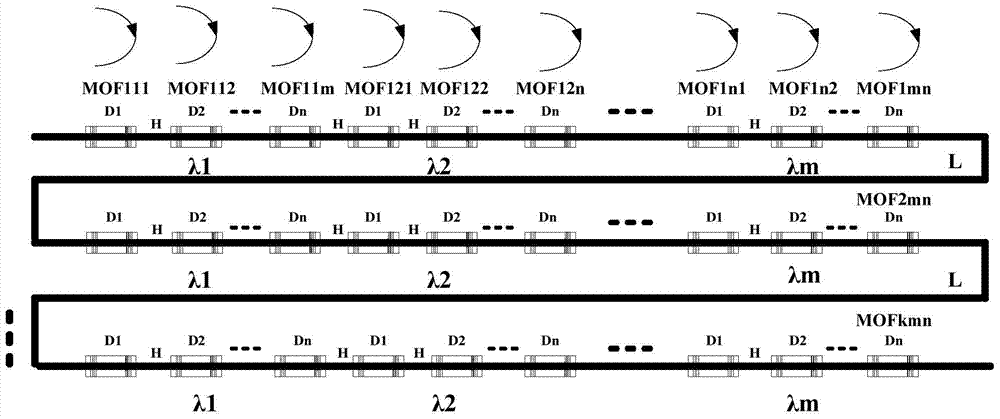

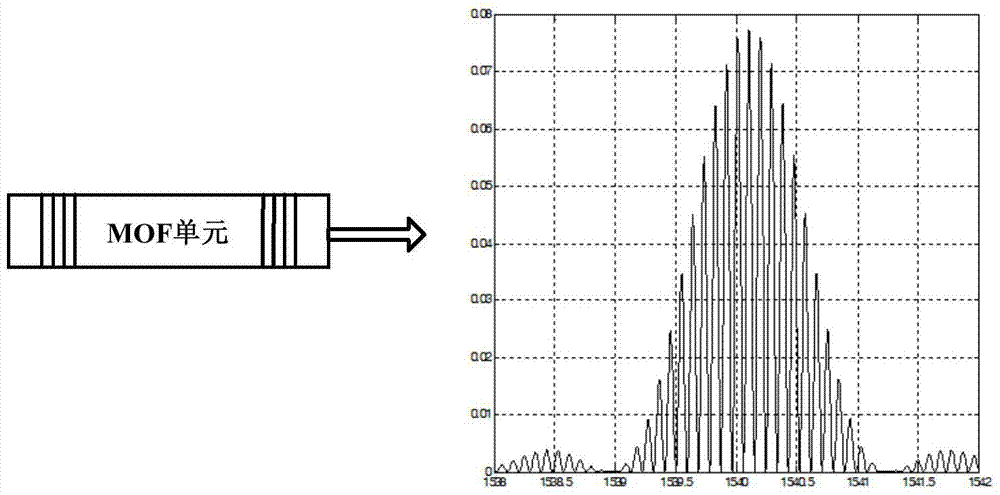

[0031] Aiming at the capacity limitation of the existing distributed optical fiber sensing multiplexing technology, the present invention proposes a distributed microstructure sensing network and its demodulation system based on hybrid wavelength division and time division multiplexing, and adopts a wavelength division / time division multiplexing network sensing architecture , and design a distributed microstructure optical fiber sensing link with three-dimensional encoding characteristics to achieve ultra-large capacity sensing multiplexing. This architecture can multiplex the sensing microstructure array on a large scale without adding demodulation devices, and proposes a microstructured optical time domain reflectometry (MOTDR ) technology, which greatly improves the sensitivity and spatial resolution of the sensing unit, and finally gives the massive information parallel fast processing technology of the sensor network

[0032] A distributed microstructure sensor network ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com