Device for realizing accurate centering of coke pushing rod of coke pusher

A technology of centering device and coke pushing rod, which is applied to unloading device, safety device of furnace, coke oven, etc. The coke rod and the flat coal rod cannot be aligned with the center line of the carbonization chamber and the flat coal hole at the same time, so as to facilitate re-calibration, reduce errors and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

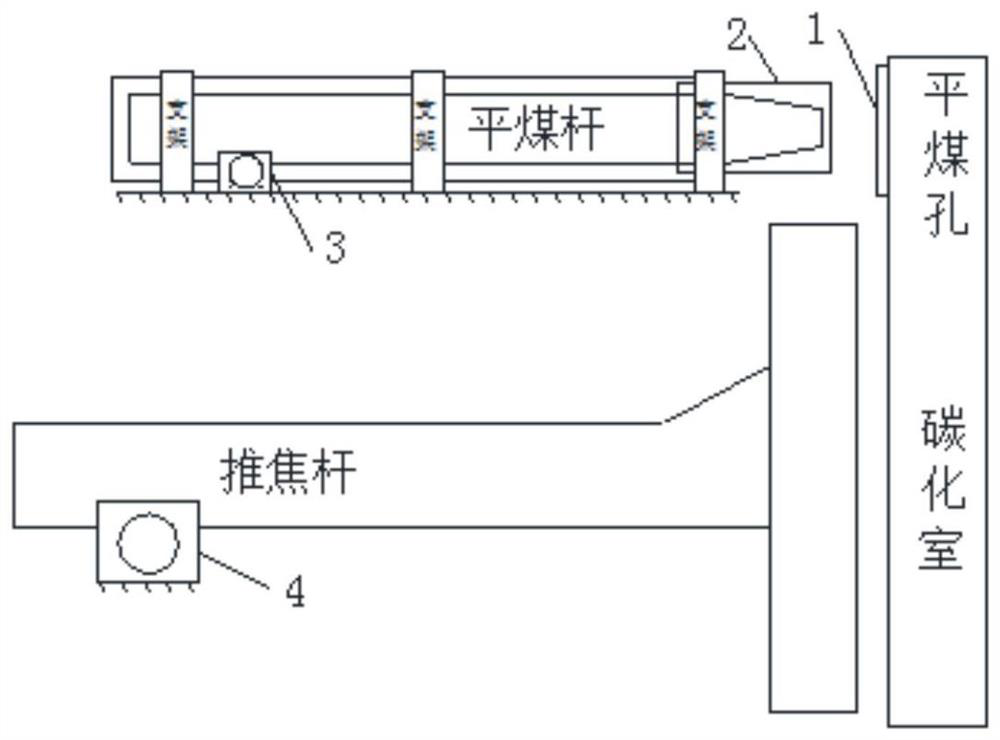

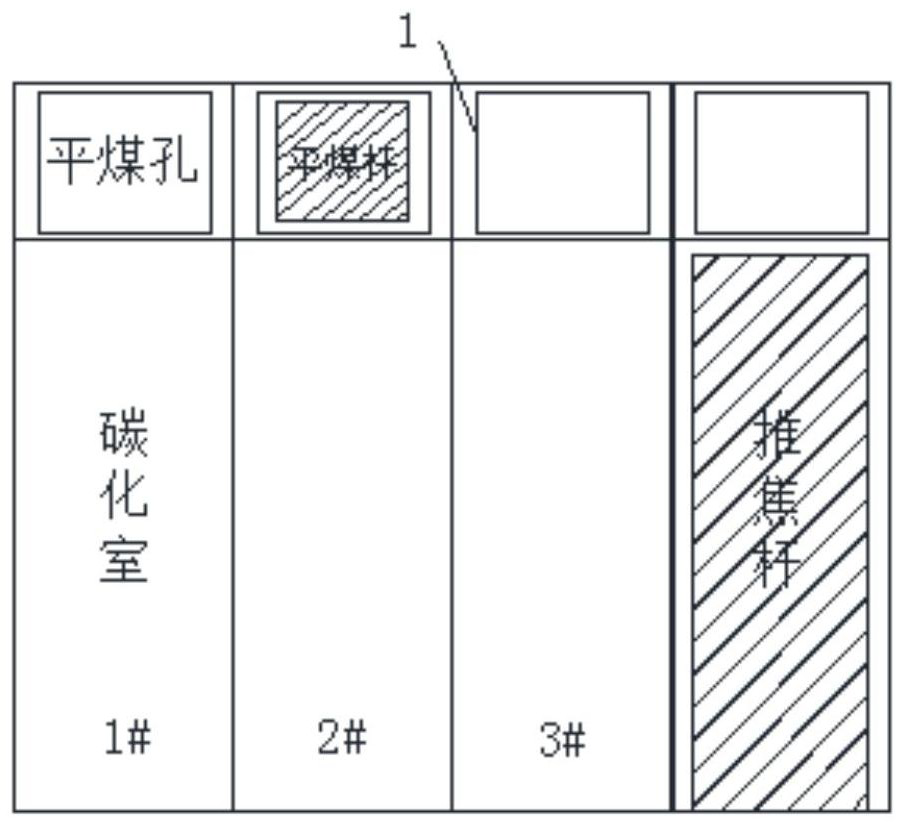

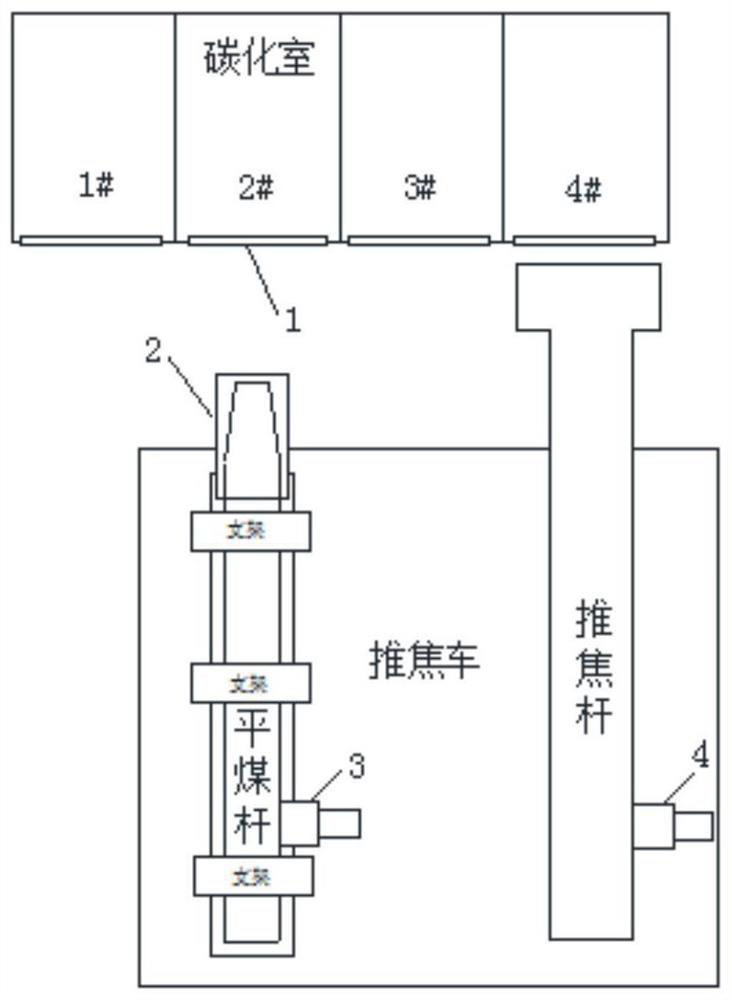

[0016] Example 1: see Figure 1- Figure 4 , a device to realize the accurate centering of the coke push rod of the coke pusher, manufacture and install the coke rod centering device, and the focus push rod centering device includes the carbonization chamber center line mark 5, laser irradiation equipment 6, front sight 7, ranging Device 8 , reflection device 9 , flat coal trolley 10 and flat coal rod moving mechanism 11 . In this example, the center line of the carbonization chamber is marked on the furnace doors of all machine-side carbonization chambers. After the machine-side furnace doors are installed in the carbonization chamber, a vertical white line is painted along the center of the furnace door with white paint for the coke push rod. Confirmation of centering position. The laser irradiation equipment is installed on the car body at the rear of the coke push rod, and is irradiated to the furnace door along the center line of the coke push rod. A front sight with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com